Woodshop Heating Options

More thoughts on the many ways to heat a woodshop. August 31, 2005

Question

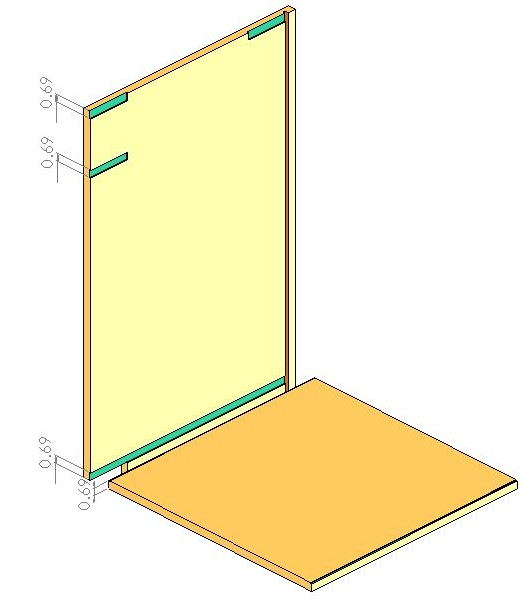

My question concerns heating for my woodshop. The building is 20’ x 12’ x 8’ on a concrete slab. I live in Maryland where the winters vary in temperature. I would like to keep the overnight temperature just above freezing and the daytime temperature in the 60’s. Last year I used a kerosene heater, but the smell and fear of combustion has me looking for an alternative. I am considering electric baseboard. Any suggestions?

Forum Responses

I use a propane "hot dawg" made by Modine. My shop is roughly equal to a 4 car garage with 10 foot ceilings. It is ceiling mounted, so it saves floor space and is easily vented outside. I have had mine for a year and a half and it works great. One problem - the relay switch from the factory that signals the fan to start went bad. My repair guy said he has seen it before - put a new one in made by another company and no problems. If you are going to be spraying, be careful.

In my home shop, I have a ceiling mounted electric coil heater from Grainger. It is on a thermostat, works like a big toaster and has worked great for 11 years now. It is in a 1000 s/f well-insulated building with lofts above, heated to a fine 68 degrees. Blow it out well in the fall is all I've ever done. Heat bill in central Indiana was about $50 a month on average.

I have a used oil furnace that heats a building that is 32'x 80' with 12' ceilings. I use 5 to 6 barrels per year, all free for the hauling and replacement with an empty container. Electric for the whole building averages about $50 a year for all fans and shop equipment.

Don't forget about your finishes and glues. Most will not do well if they are brought down to cold temperatures. Even if you keep them from freezing, it takes a long time to bring a bottle of glue or a can of finish back up to a useable temperature. The materials should also be above the minimum temperature before using glue or finish on them. I would recommend keeping these in your basement or someplace heated. Or you can do what I do up here in sunny Boston - keep the heat at 50 overnight and tack a few extra dollars onto your winter jobs.

You may want to rethink your plan to allow the temperature to drop to just above freezing, as that will cause condensation to build up on your tools and create rust problems.

Sshcinc.com sells a woodshop series of ceiling-based radiant heaters that seem to work very well. I know of one shop in the Hartwood area of Virginia that uses these heaters.

From the original questioner:

Thanks for all the good advice. I have installed an 8' radiant heat baseboard heater, which works fine for me. At night I turn the thermostat down to 45 degrees, which stops my paint, glue, adhesives, etc. from freezing. The heater is wired for 220 and I'm anxious to see what effect it has on my eclectic bill.