Message Thread:

Contemplating a cnc router

1/2/18

For about the last year Iíve kicked around the idea of investing in a cnc router. At this point Iím trying to figure out just how much it would benefit me in the long run. I build face frame cabinets, (in my area people just donít want frameless but the traditional look is what is popular. And for some reason, the more rustic the better) so I plan to continue with the face frames. So Iím guessing sheet goods would be the primary use for a router. I can definitely see it saving time with some of my components, and from different videos Iíve watched Iíd have quite a bit less waste. Iím a small two man shop, the only thing outsourced is turnings and anything with carvings. Iím ignorant on cnc but I do learn quickly so Iím aware that it would take some time to get the bugs worked out before it would actually be profitable. I design using kcd which is cnc capable but I donít have that unlocked since I didnít need it. So here are my questions.

How much time would it save me?

How long would it take for the router to work for me instead of me working to pay for the router?

Is it worth the investment if I only cut sheet goods, or would it open up a whole new realm of capabilities that would make things easier/faster?

If it does save time at the table saw am I going to be spending all that time at a computer?

Then there is the question, if it is a good investment which would suit my needs the best? Software? I know little about these but it looks like ShopBot or the legacy maverick is possibilities. Iím not looking to invest a great deal, if I canít do it for 20-25k then Iíll just keep things the way they are. Having no experience with these machines I really just donít know what all that it could possibly do for me. So any thoughts as far as pros and cons and brands and models that are in my price range would be appreciated

1/2/18 #2: Contemplating a cnc router ...

Mike,

Describe your current setup. cabinet software?

primary sheet saw: Unisaw, track saw, slider, panel saw?

cabinet box construction?

What drills the hardware/shelf holes?

1/2/18 #3: Contemplating a cnc router ...

Website: http://MCCWOODWORKING.COM

Website: http://MCCWOODWORKING.COM

If all you want to do is what you are doing, why add new equipment? A CNC could open up a lot of possibilities, too numerous to mention here. One obvious possibility would be European cabinetry, not Frameless and I do not think there is anywhere in the country that you cannot sell Euro.

Limiting yourself to a budget of $25,000 will limit the offerings. See what other shops are doing, talk to sales reps, they get into lots of shops. When I bought my CNC, I had no real need for it, but today it is the heart of my shop.

1/2/18 #4: Contemplating a cnc router ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

I went to a cnc in 07 after 20 years of self machining, Good due dligence will lead to a successful switch to a cnc, face frame or euro require boxes, boxes are cut on a cnc, this is the initial use, I found other streams of use and we are three times the size we were when we went cnc, I always advocate going to shops like yours and a bit larger in your area and see the machines see the owners, the time will come when you need an answer on a weekend or near the end of the day when a tech will not be available these friendships become invaluable. both Camaster and shopbot have forums and maps of owners all over the country, and whatever machine you purchase these visits will pay off. Don't buy quick, don't buy junk, don't buy and expect it to run a job at arrival, it will be a process, take your time it will be worth it.

View higher quality, full size image (1024 X 681)

1/2/18 #5: Contemplating a cnc router ...

Are you at capacity? When a CNC is up and running it is a brainless operation. Load sheet, hit button unload finished parts.

I don't know KCD but if it's setup correctly you should spend very little extra time at the computer.

The router is foundational to our operation. I can't imagine going back.

I agree that frameless will sell anywhere. Most people would not know the difference.

Good luck!

1/2/18 #6: Contemplating a cnc router ...

James how do you like the Cam Master router? I am in Georgia so Cam Master isn't that far from me. They seemed to be priced great compared to larger brands and machines like SCM or Weeke or similar.

1/2/18 #7: Contemplating a cnc router ...

Thanks for the good responses. Let me see if I can describe my process and set up a little more. I design and print drawings from kcd software. I process everything on a Unisaw. We do all the door building first, then face frames. At this point while one guy sands the doors and another guy sands the face frames Iím cutting all the other parts like running the crown, finished ends, drawer fronts, toe kicks, etc. By the time the face frames are sanded then Iíve usually got a bunch more done for that guy to sand. I mentioned previously that I was a two man shop but just now said that I had two guys sanding, thatís because one of my guys just quit right before Christmas. He had been with me for 16 years and finally had to give it up due to health reasons. I thought long and hard about who to hire to replace him and then decided not to hire back and I have peace about that decision. Iíve been doing this for 20 years now and Iíve worked way to many long hours and 6 day weeks. So I feel that if I donít have to pay that wage then I donít have to make as much either. Thatís actually what got my mind back on the whole cnc thing. Running a cnc might be like hiring another one of me instead of hiring another laborer. So I guess Iím like James, Iíve done it for 20 years manually, and I figure Iíve got close to another 20 before I think about retirement.

Paul, I donít mean to limit myself. I really just donít know what all would be possible if I did have cnc. Iím sure when and if I do then I would see all the limitless possibilities. It may completely change the way I do things. You mention euro not being frameless? I thought they were the same thing? The reason that I say I couldnít see frameless is the responses that Iíve gotten through the years. ďI donít want any of that flake board in my cabinetsĒ. ďI want good strong cabinets, none of that flimsy stuff that is a box made of plywood, I want a frameĒ. I know the dispute of face frames vs frameless has been discussed to death here so I donít want to get into that argument. Right now I build face frame cabinets, use 1/2Ē prefinished ply for everything except shelves which is 3/4Ē. Actually I could see my market going to inset cabinetry before I could see it going to frameless.

Paul, you said you didnít need a cnc when you bought one and now itís the heart of your shop. Thatís one of the reasons that Iím contemplating it, I donít know what opportunities it would open up, I just know Iím making it without it. But wondering what could be.

James, I appreciate the good advise. I donít plan on buying quick, I tend to ponder and research maybe more than I actually should. It took me two years to buy a box truck once I started looking... the one thing I donít want to do is buy something and wish that I had gotten something bigger or better. I appreciate the pic, camaster is one of the machines Iíve been looking at, seems like itís very popular. I do have one friend that has a cnc locally. I agree that finding friends with the same machine would be invaluable. I do have a feeling that if I do get one then I will kick myself for not doing it earlier. Change is hard.

1/2/18 #8: Contemplating a cnc router ...

I am semi retired and bought a small CNC, it is amazing what you can do with them and some training. I bought a small one. this company has various different ones.

The company is DWC, and the sales rep is amazing, he is always available for help and answer all questions and will provide training.

Laney is not a 9-5 type person, he knows the software and the equipment, he doesn't just sell it and forget about you.

His phone cell phone number is 352-404-3951 ( he is located in Florida, and the company is in Indiana).

1/2/18 #9: Contemplating a cnc router ...

A cnc will change how you do and what you do. For an x-mas party. I cut 4'x4' musical notes out of 2" foam. Never would have done it without the router. There is just me and a part timer. I bought a router three years ago. I wish I had bought it sooner. When thinking about the router. I wonder how to put a price on my health. The wear and tear on my body. By lifting and totting all day. Now I slide sheets onto the scissor lift. Roll it to the router. Slide off. Then route. I can cut a kitchen in a day and still feel like going to play with the horses. While it's routing. I band, sand or whatever.

The learning curve. I had little experience with cnc. I kept going to forums. Reading everything. Watched you tube videos. When I decided what I wanted. I read their forum for a year. Everyday. When I got the machine it wasn't a total learning shock. Do I know it all NO. Learn every day. I do find it's nice with a 5' wide table. Take the time and go to the IWF this year. Look at all the machines there. Ask many questions.

1/2/18 #10: Contemplating a cnc router ...

Definitely following this thread. I'm in the same boat as you are Mike, probably a little closer to pulling the trigger on a purchase though. I'm at the requesting quotes stage and comparing options which I don't mind admitting is overwhelming. My main fear is the learning curve not being a "computer guy"

1/2/18 #11: Contemplating a cnc router ...

Website: http://MCCWOODWORKING.COM

Website: http://MCCWOODWORKING.COM

I bought my router in 2000 and I had all the fears mentioned above. I felt great relief when I hired someone with experience on the router I bought. He quit after three months. He knew how to run the router, but he did not know how to build cabinets or what I wanted to do with the machine. I had to start to learn from scratch. I tried a few other people, and then took a class on AutoCAD. In two days, I was cutting parts. I paid $75,000 plus another $5,000 in bits and tools. I bought an AXYZ, with a working table of 144" x 80". The machine was designed to do counter tops.

I suffered through six months, totally learning on my own. I was 50 at the time and when I took the AutoCAD class, I did not know how to turn on the computer. I asked and asked again. The instructor thought I was a pain in the ass, so I spoke with him after a class and he then understood that I need that class and everything worked out.

You will have a lot to learn. Like, where do you make your start point and which way do you have the router cut. Do a climb cut on solid wood. I had problems holding the parts down. What sequence do you run you groups and why?

When I bought my machine, AXYZ was just getting into using tool changers and they were very slow, so I had drill heads mounted on the side of my router. One drill for the 5mm holes and one for the 8mm holes for my dowels. There is a learning curve to everything. If you have been doing cabinets for 20 years, a CNC is like magic.

I read your comment about Frameless being junk. I felt the same way until I went to a few shows. I call it Euro because that's what sells. Everything about cabinetry that is new and exciting is Euro, coming from Europe. I found that when I started to build Euro style cabinets my material costs went up but my production doubled.

My machine was made for countertops. It has a digitizer on it and I can trace a template, down load it to my computer, make my drawing from the template, down load a CAD DXF file from the sink manufacturer, Kohler, American Standard, etc, insert it into my drawing and that takes about 20 minutes. Then, I down load it to the router and I can cut parts for the top. I cannot tell you all the details of how I do it, but you get the idea. We usually cut at 350 inches a minute. That might be slow, but that is pretty good when you are cutting out a blank for a laminate top. Solid surface is cut at about 60 IPM.

Ever need a corbel for a shelf? How about an deco toe for a cabinet? What about a curved wall? How about a tapered column for a builder or a dozen of them? How about a curved stair? The list is really endless. I do things no one else does, it is great fun.

Visit my Web site. Curved handrails, don't stop while you are running it because it will lift up and "Oh shit!!!". How about an arched molding? We cut stair stringers as well. Cheaper than a builder can do it and perfect if you know how to build stairs. Every part for the curved stair on my web site was cut with the router. But, I am not a two man shop and I have an excellent drafts person to help with drawings.

Anyway, good luck. It will be stressful, but once you learn the basics you will see many more opportunities. I didn't even mention working for sign companies. In my area, most of the signs made with Signfoam were done by us.

1/2/18 #12: Contemplating a cnc router ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

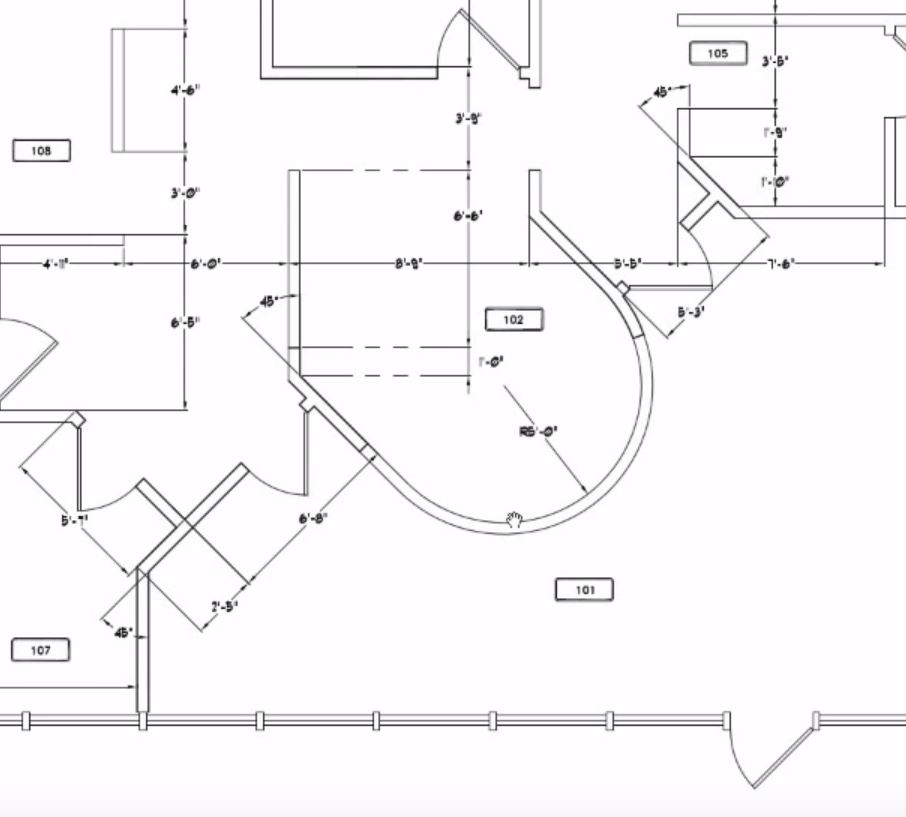

I had not seen this Video for a while but thinking of this post i looked it up, i did this a good 5 years ago and I have excelled far since then. Yet i was really tickled at how overall easy it became !

View higher quality, full size image (906 X 817)

View higher quality, full size image (1024 X 683)

View higher quality, full size image (960 X 720)

https://www.youtube.com/watch?v=5APCVuxhxOM

1/2/18 #13: Contemplating a cnc router ...

Mike,

You actually can do it for $25k. Check out Omni CNC. It's chinese. You can get a decently equipped router for about $20k, and you'll need another $5k to upgrade KCD to the CNC version and get a post processor for your machine. Then you're off and running.

I use KCD too. It's kind of a no brainer. In this economy, you'll earn your investment back in less than a year.

1/2/18 #14: Contemplating a cnc router ...

Mike,

I'm going to weigh in on the opposite side of this somewhat. I did what you did and examined all of the data. CNC is awesome under the right circumstances. If you are doing quantity, trying to cut labor costs at certain quantity levels or do a wide range of radius, cut outs, etc.

But I'm never going to cut out music notes and I have no desire to get into radius work that a CNC would speed up.

At the price point you are looking at I can do at least double, possibly triple, the amount of cutting and milling of parts with manual equipment versus the CNC of that price point in the same time frame. Certainly racing one of the bigger machines is a fool errand in the long run. Of course the machines are going to be more accurate, but not enough to make a difference to those in the field. The installer won't be able to tell, let alone the client.

There is no doubt at a certain quantity level a CNC is a no brainer, hands down or if you want to do some of the things the other gentlemen are talking about and wanting to expand your product line. So in other words I think it comes down to what you want to do quantity wise and range of work you want to do.

Much like when I'm working on something I want to focus-loading a sheet and walking away for a couple minutes to sand, band, etc would drive me nuts and lower my efficiency- I also like to focus my product line.

I know it's a minority opinion. CNC are great. They just aren't for my business. Perhaps they are for yours. Good luck with your decision. Hope it works out for you.

1/2/18 #15: Contemplating a cnc router ...

Hi mike, I am a small mom and pop shop that is in the same boat as yourself. I have been subbing my CNC work to another local company and so far it has been going well. I bring this up as you might want to try this first to see how things go and how efficient things can be. Why, at your age, it might not be worth it to buy a machine, but just sub out to other shops. I have found that with my lifestyle, itís better to not take on debt and overhead, but to ride the economic work waves as they come. Just another thought.

Hey Paul, where are you in NorMich? Iím up in Harbor Springs, good to meet someone close on Woodweb

1/2/18 #16: Contemplating a cnc router ...

Have you considered a pod and rail machine? Most have a router spindle and stand alone machining software that can be programmed right at the machine.

I have a Weeke BP 60.

I cut sheet goods on a Striebig then machine for dowel or confirmat screw assembly.

It does construction holes, line bores for adjustable shelving, bores attachment holes for slides and hinge plates and can saw the groove for the back (though I build frame less and confirmat the 18 mm back)

I would second that you could sell

frameless ... you just have to sell its benefits to yourself first...

I honestly haven't been asked about construction method in 20 years, but most homeowners are impressed with the strength of the confirmat screw assembly.

I have been asked about material used for cases.. (I use 18 mm veneer core birch- sides, top, bottom, back and shelves, also requires stocking just one sheet product other than finish species)

Most homeowners have a phobia, justified or not, regarding particle board, and 1/2" wouldn't work with frameless

Going frameless would lend itself to less assembly labor (assuming you have an edgebander), allow you to lose the face frame material and labor, and standardize assembly and hardware installation

1/2/18 #17: Contemplating a cnc router ...

Great video James. I was watching a YouTube video earlier today of an IWF video on the CAMaster router where they were talking to a Jim Mcgrew, I thought that had to be you, to big of a coincidence.

Wondering if you cnc owners could give more info on table size. It seems that the difference Iím seeing on many brands is only 1k to go from a 4x8 to a 5x8? I donít know why a 5í wide would be needed unless you process 5x5 sheets, which I do occasionally.

Also, in my learning process of bit changing it appears that an automatic bit changer is an option but expensive, or what appears to be a main spindle and two additional routers which hold different bits. This seems to be the best option to me or is it?

Sorting through brands is like trying to get the pick of a litter of pups, some are pretty but will it be a good dog or lie on the porch and want you to scratch his belly? The CAMaster at this point looks like a good option but which one would I want is up in the air, itís hard to know what your needs are when you donít know yourself. I have a history of getting a piece of equipment that I can afford only to wish six months later that I had gone bigger. I donít want to make that mistake on this. The ShopBot is another option, it kinda looks generic compared to others but I realize that has nothing to do with performance. The Legacy machines looks like itís full of options also, Iím not sure Iíd want to do the turnings, looks like even with a cnc there would still be a lot of sanding to do. Is it still better to outsource some things even though you have a cnc that can do it?

Anyway, at this point my plan is to read and research, learn all I can until August and go to the IWF and look first hand. I think Iíll know a lot more about what Iím looking at and the options available and what I plan to do by then.

1/3/18 #18: Contemplating a cnc router ...

Family Man, this same question was posted earlier this past year and my reply to it was almost identical to yours. I can cut a pretty big kitchen worth of sheet goods in a days time and line bore, etc. but then another reply on that thread someone mentioned it was like hiring another worker that knew what I know to do my job while I went and done something else. That made a lot of sense to me. I canít tell you at the times when Iíve told potential clients my time frame and they have told me that I need to hire more help, to which my reply was, I donít need more help I just need more me. So with me being short handed now I see this as a possible opportunity to hire someone with my knowledge and not have to pay them like they know what I know. I really think it will help with some of the time consuming things that I do. I try to be creative in my designs and this would open up new possibilities. Not to mention the older I get I could possibly do some things on it to bring in income that is not back breaking work.

Matt, I have let another shop do some cnc work for me before, wasnít any problem with it, just took me a while to get there and get back. I try to keep as much in house as I can. As far as my age goes, Iím not in my prime but not over the hill either. Iíve been a fairly smart businessman I think. Iíve never financed or leased and equipment, Iíve grown as my wallet did. Iím not in debt other than a Kubota tractor that will be paid off in June, which would be about the same payment as a cnc would be. Plus Iím not talking about an investment thatís going to take forever to pay off, if we are realistically talking about 20-30k you canít hardly buy a new truck for that anymore?

1/3/18 #19: Contemplating a cnc router ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

My first machine was 4 feet wide, my 2nd thu the current 5 x 8 have all been 5 feet wide, i neede the 5 feet for a lot of reasons as we now cut commercial at 61 x 97 sheets, well worth the extra money, to me a cabinet maker needs 5 x 8 table 5 zone vac plenum, good vacuum hold down and an ATC of 5-8 tools

1/3/18 #20: Contemplating a cnc router ...

This is probably not what some want to hear but I will say it because it needs to be said.

Before we had a router we had the saw guy. I was the saw guy for years. There is a lot of knowledge in the saw guys head. He also likes to cut standard stuff. When something custom or unusual comes up he slows down a lot. Sometimes he cuts the normal version before he cuts the correct custom version. He also goes on vacation, gets sick, takes another job, has a bad day and may have an issue that makes him miss weeks of work. A saw no matter the quality no matter the operator is not perfect every time.

Right now my newest employee can run my router cell, rout all the parts, edgeband and bore. I did not set out to have him do it and he is not my main guy but he can run the machine. As can I, as can the shop manager. I have 4 people that can run that machine efficiently. It is faster than a sawyer could ever be. It can do things that can not be done easily on a saw. It can do complex things over and over and it comes out the same. If a part is damaged it can easily be redone quickly. There are no special setups or fixtures.

I can't really speak for a two man shop, I did not approach it that way but a router is a way for any shop to be much more efficient, flexible, accurate and creative.

If you are in the $30K range ask yourself a question. Who could you hire for $30K for the next 10 years to cut all your sheet goods (plus other things you don't realize right now). Even if you are the saw guy your time is best spent elsewhere.

An example that might resonate would be the thinking "I am not using that new circular saw, my hand saw is tried and true it took me years to become an expert." Another example is when sheet goods were created and the cabinet maker said solid wood is the best solution, that plywood is not real craftsmanship. Sounds ridiculous now but I am sure that thinking was prevalent.

The market has changed, the technology has changed. Routers are affordable. Do you really want to stick with the handsaw?

Our first router was the best investment I have ever made in anything. I bought a stout European machine, I sweated the purchase price. In hindsight I should have gone larger. Eventually I did and now we run 2.

Some things that have been mentioned and some things that have not.

A router has nothing to do with radius work. Sure it does that well but that is not the point.

Our router saves money on tooling. We can cut more sheets with a less expensive tool that cost less to sharpen than a saw.

Your yield will go up no matter the person on the router.

Your creativity will be enhanced not taken away.

Your ability to solve problems will be taken in another direction not taken away.

There is less scrap to throw away.

Get a toll changer, I always want more tools.

Get a drill head if at all possible.

Some downsides.

You must have a company with excellent service.

You must have a company with excellent service.

Saving money on the front end will be lost if the machine is not reliable. They must have people in the field that can help. Not a guy but a company that will continue to function for years for sure. If you can't afford the machine you know you should buy wait. Don't buy a no name router. I would stick with known names, companies that have been around, proven.

Once a company reaches critical mass it is time for a router. I do not mean to offend anyone but this to me in hindsight is obvious.

Good luck to the OP.

1/3/18 #21: Contemplating a cnc router ...

Website: mcgrewwoodwork.com

Website: mcgrewwoodwork.com

Bill, That was well written and some damn good advice.

I am going larger this year, trying to make a new building decision and incorporate machinery installs on that

1/3/18 #22: Contemplating a cnc router ...

We have had our router for 8 years now.

4x8 Omnitech and Cabinet Vision software.

Best thing I ever did.

We are a 3 person shop and can now take on larger projects then I ever would have tackled before.

Another option is to find a local shop with a CNC and have them cut for you.

We cut for 3-4 shops right now. For one of them we cut all of their work.

He emails me his cabinet list, I enter into our software and send him simple drawings of each cabinet. He signs off on the job, we machine, band and assemble for him.

He now has the supplier drop his plywood at our shop.

View higher quality, full size image (1632 X 1224)

1/3/18 #23: Contemplating a cnc router ...

Website: http://MCCWOODWORKING.COM

Website: http://MCCWOODWORKING.COM

Some great posts here. Bill said it all as did Jim. One comment I noticed. "At my age". The CNC is a lot of fun. I just turned 68 and I have no interest in retiring. I work for people that have retired. A lot of them set up little wood shops in their garages or pole barns. Most of them watch way too much TV. I cannot imagine anything more fun than what I am doing now. And, the CNC makes that possible.

1/3/18 #24: Contemplating a cnc router ...

If I was a two man shop, using KCD, I'd send a few jobs to Cabinotch to test how much speed you would gain by outsourcing the boxes. It's a lot cheaper than a CNC, you know the exact cost of the boxes to the penny, and you won't loose any time while learning software and machine operation. Also no time on the phone with tech, with both the software and CNC machine company. Then if you don't see the advantage of outsourcing, then shop for the CNC. You can really make some time with the prefinished plywood box parts.

1/3/18 #25: Contemplating a cnc router ...

More good points and info that I appreciate.

Jim Herron, I didnít even know what a pod and rail machine was, had to watch a YouTube video to know what you were referring to. It appears to be similar to a router but I just donít know the difference. Iím in kindergarten on all this stuff.

Bill your comments make perfect sense, and I agree with James, itís good advice. I guess I just always assumed that these routers were for the bigger shops bringing in more revenue and it was out of reach so I never gave it much thought, much less researched the possibility of owning one myself. Your comments make me realize that I probably should have done this several years ago.

Paul Miller, I like your outlook. When I say ďat my ageĒ Iím saying that itís not like Iím nearing retirement even if I did want to. I think a previous poster was saying ďat my ageĒ I might want to think about not investing. I was thinking at my age it would be safe. If that makes sense, I plan on working for a long time yet. As far as the fun part goes, I think itís fun now, I enjoy working and creating the things that Iíve done, and evidently Iíve been going about it the hard way. I can see a router letting me get off my feet a little more also and not constantly walking back and forth between a table saw and a plywood rack. I do have some back issues.

rich.c

I understand what your saying, Iíve checked out cabinotch a little. There has always been a debate on here about outsourcing and whether it is profitable or better to build in-house. I guess itís all about what we want our end game to be. I outsourced doors until about 3 years ago and then I bought the equipment to do it myself and it paid for itself in no time. So I guess if one wanted to they could outsource the doors, let cabinotch or as some of the others have said another Shop could cut the parts. I think it was Bob that said he even bands and assembles another shops cabinets for them. If you sub out the finish work as well then youíre no longer a cabinet shop but a middle man. And thatís fine if thatís your end game and what you want to do to make your living, nothing at all wrong with it. I know a guy right now that has amazing talent and was doing good in his shop, then just quit and started buying rta cabinets and assembling. His reasoning was that he could buy a set of cabinets and put them together cheaper than he could buy a set of doors for. He still does it and has done well. As for me, itís not all about the money. Iím like Paul, I thinks itís fun and I like doing it. Main thing is be happy at whatever you do, life is to short to work a job that youíre not happy in doing. That just my opinion on it.

1/3/18 #26: Contemplating a cnc router ...

I'm not in business to make cabinets, I'm in business to make money.

1/3/18 #27: Contemplating a cnc router ...

I know a lot of folks don't like outsourcing, saying they want to keep the craftsmanship in house. But the difference between having someone else pushing a button to cut boxes out, vs. you pushing a button to cut boxes is pretty thin in my opinion.

1/3/18 #28: Contemplating a cnc router ...

We have a decent sized shop with a cnc router, a larger bander and dowel/insert, we run a lot of commercial casework and lots of corian I am getting ready to get a cnc saw for our stone shop @ the end of this year for the automation

We own two forklifts, the Blum machines we added 20 years ago came with the same " why did we wait so long ?" same as the edgebander, wide belt and then the cnc. We run CabinetVision, again beating our heads against the wall we just went to CV10 and hear the what took so long ? We have 5 seats and 2 s2m keys. All of the upgrades and all the equipment has been great, but hands down the cnc, soft ware, bander and forklifts have saved us years on our bodies

So my friend runs a hi end residentail shop and would never buy a cnc, I cut a house full of cabinets for him with mine in 4 hours, And I am talking 40 plus cabinets He bought my older edgebander, a cnc and now uses prefinished plywood, outsources his doors with Walzcraft, does all his own finishing and pays one of my installers on the weekend to help him goes through guys like water, but the cnc keeps cutting

1/21/18 #29: Contemplating a cnc router ...

Get a auto toolchanger. Unless it's just a hobby machine, you're going to be really really glad you did.

CNC is bunch of money to a new buyer and a bunch of learning and messing around at first. You will probably change some things on how you build your boxes.

4/3/18 #30: Contemplating a cnc router ...

Website: http://www.hicasmachinery.com

Website: http://www.hicasmachinery.com

The cnc router is a very versatile function. For engraving purposes, efficiency is not to be discussed because of patterns, textures, and graphics. Both limit efficiency. Used to make panel furniture production, atc cnc router, will be the best choice. High efficiency, low labor costs.

This video will be more clearly expressed.https://www.youtube.com/watch?v=PUQvXA_ZC6s

View higher quality, full size image (1000 X 1000)

View higher quality, full size image (1000 X 1000)

ATC CNC Router

9/28/20 #32: Contemplating a cnc router ...

Website: http://forsuncnc.com/

Website: http://forsuncnc.com/

If you are looking at buying a CNC Router, please consider these insights:

1. Choose a suitable CNC Router model with an ideal working size

2. Choose the Right Type of Spindle

3. Get to Know More about the Transmission

4. Know the Servo Motor and Stepper Motor

To learn more, you can check this article: What is a CNC Router? (Buying Guide)

View higher quality, full size image (942 X 621)

View higher quality, full size image (510 X 510)

What is a CNC Router? (Buying Guide)

|