Flatsawn to Quartersawn

Cutting both types of lumber. December 17, 2003

Question

If I rip a flat sawn board down the middle, will I end up with two quartersawn boards?

Forum Responses

From Gene Wengert, forum technical advisor:

No.

From contributor A:

I guess Gene is suggesting that doing this may leave some undesired effect to the boards. I am familiar with Qsawn on swing mills but bands are unfamiliar territory for me. The core must have to remain.

From contributor A:

Oops, I assumed that you were talking about a flat board cut through from the centre of a log. Not simply ripped in half.

From contributor B:

If the board in question comes from the center or near the center of the tree, the wood on either side of the center will be quartersawn. If you remove the center section, the two boards left will be quartersawn. I would suggest you buy a copy of Bruce Hoadley's book "Understanding Wood." It is an excellent reference.

From the original questioner:

That's exactly what I was wondering... It seemed to me that as long as the flat sawn board was near the center, either side of center is quarter sawn grain, thus allowing you to rip the board to achieve quarter sawn results, as long as the center is removed.

From contributor C:

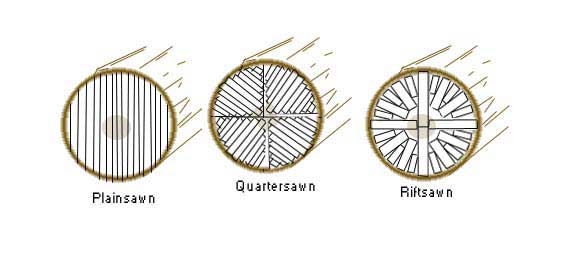

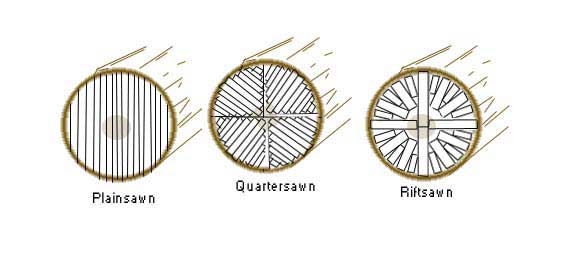

If the board in question is near the center of the log, it is not flatsawn, it is Qsawn or rift sawn depending on the angle of the grain. You cannot take a flatsawn board and split it to get two Qsawn. What you are doing is splitting one QS board and getting two QS.

From contributor B:

Actually, a center cut board will have a flat sawn section near the pith.

From Gene Wengert, forum technical advisor:

There seems to be some difference of opinion here. In truth, a wide board going to bark to bark that comes from near the center of the log is q-sawn on the edges, riftsawn further in, and flatsawn in the center section. Because of the flatsawn section, the piece cannot be classified as quarter or rift. That leaves flatsawn, although some people would call it bastard sawn. Contributor B is totally correct that by taking two rips at the appropriate locations (perhaps 3" either side of center), you will end up with two rift (or q-sawn) pieces and one flatsawn piece.

Rift is often applied to pieces with the rings at 45 to 75 degrees to the face, while q-sawn is 75 to 90 degrees. However, sometimes q-sawn means 45 to 90 degrees - this is not the preferred definition. This confusion is also why most lumber is sold as "quarter and rift."

From contributor D:

If you rip a flat sawn board, you end up with two flat sawn boards and some sawdust. If you turn it on its edge and take thin slices, those slices are wonderful quarter sawn strips. They make great crack covers, like when you butt two pieces of plywood together and whatnot.

From contributor E:

If you take these boards from the middle of this log, they are Qsawn. You should leave it together and dry them, then straight line rip them into good boards. By leaving them together they will bow less.

Yes, there is a small bit in the very center that would be flat sawn, but it would be low grade and trimmed off anyway.

You will know when you get it right.

From contributor A:

Leaving the board intact through the drying process would tend to increase your chances of the ends splitting, wouldn't it (apposing tension from the heart, in some cases the core, is very prone to shrinkage)? More so the hardwood.

From Gene Wengert, forum technical advisor:

Contributor E has given excellent advice... do as little processing as possible before drying. If you rip before drying, side bend warp is common. If you do not, some end checks may form in the low grade, but that is not a problem usually.

From contributor A:

One technique would be to make some sort of lathe that has spikes at each end to stab the core so the log can rotate. You could cut vertical boards on each turn to increase the quality of Qsawn (the first few cuts where you enter would have less grade but the remainder would be top grade). The lathe configuration would need a lock system for each partial rotation. I've seen easy lathe gadgets that can achieve this.

A simple solution to reduce bow in qsawn is to steel strap your pile down with 4x4 all the way round flush so no stress can happen.

From contributor E:

The wide qsawn boards may check but will do it at the pith most of the time and not be a problem. I have several of these air drying that are 28 inches wide. Like the Doc said, save the trimming till they are dry and you will get wider and better boards.

If you look at my first picture you will see where I took 4 boards from the middle of this log. I rotated all of it 90 degrees and removed the 4 boards and clamped the 2 halves back together and made 5 more cuts that produced 8 boards this time. Then I saw the pies (4 of them) if they will make 6 inch boards. If not, I clamp them in and flat saw them to the deck to save on waste. On my Wood-Mizer it is easy to center the pith on each end and that makes for good rays from end to end of the boards. If you have a log with a knot put it in a pie.

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).

Comment from contributor K:

I am providing an illustration to help show the appropriate cuts for flat, rift and quarter-sawn lumber. Notice how a board cut directly across the center bark to bark meets the rift cut qualification after the core or pith (center of the log) is removed.

Click here for full size image

In theory, simply putting it, if you do not rip the lumber prior to drying the grain will have a better chance to dry evenly as the bond moisture evaporates from the cells. Really this is all a matter of opinion and luck. Depending on species and origin of the timber, the lumber may even bend after removing the core and after even reaching 0% MC.