Question

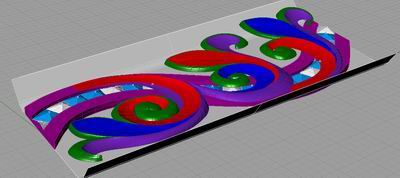

Is anyone else doing 3D work on CNC machines? Here is a picture of some of my work. Let me know what you think. I would be happy to answer any questions you might have about this kind of work.

Forum Responses

What brand of software did you use? What type of CNC? What is the material? Is it some type of foam? And last, what is the piece part of?

What markets are you after? Does your CNC have multiple heads or a single? Again, your piece looks great!

I typically use about 5 or 6 programs to accomplish any of my pieces. I only used 3 on this one..

I freehand sketched the layout in Rhino, swept and lofted the surface. I would normally take a design like this into Mastercam to build a more intelligent tool path that follows the sweeps, but this time I opted to convert from NURBS to mesh. I touched the mesh up with Z brush a bit and let Desk Proto raster it out with an 1/8" ball. Took a while to cut but I'm pleased with the design.

When it comes to 3D modeling, I try to use apps as far away from CAD CAM as possible. The problem with CAD CAM modelers is that they build the modeling tools around the limitations of the target machinery. I have found a lot of my best utilities in CGI and GIS.

The material is precision board that is typically used in Signage.

I used a Multicam A103. No tool changer, thus the simple tool path.

As far as markets go, I have been doing freelance CNC programming mostly in the areas of 3D and 3D art for CNC. I have been thinking of releasing some video tutorials showing the CNC world how to use lesser known applications that don't necessarily pertain to CNC and manufacturing.

Editor's Note: For imported machinery from Casadei, Busellato, Vitap, Bonacin and more, see JKL Machinery (website).