By Carl Hagstrom

Carl Hagstrom is the Systems Administrator at WOODWEB.com, and a

contributing editor at The Journal of Light Construction. Many thanks

to Gene Wengert, Professor Emeritus at the University of Wisconsin,

who has written extensively about wood movement during his many years

of participation at WOODWEB.

Most finish carpenters are aware that seasonal changes in humidity cause trim and flooring to shrink in the winter and expand in the summer. But few realize that the expected movement can be accurately predicted and potential problems avoided. It's my premise that with a moisture meter and an understanding of wood movement, most wood movement problems can be avoided. Plus, with this data finish carpenters can accurately predict how trim and flooring will behave after it's installed. In this article, I'll explain the importance of understanding wood movement, and how to use a moisture meter to measure the moisture content (MC) of trim, how to decide when a load of trim should be rejected, and how to accurately estimate how much trim will move after it's installed.

Wood Movement - You Can't Stop It

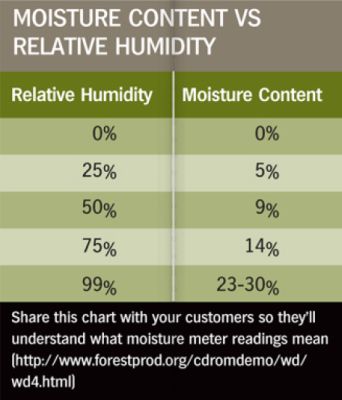

Wood is hygroscopic, which means its MC will fluctuate based on the relative humidity (RH) of the surrounding air. As humidity increases, the MC increases, and the wood expands, and as the humidity decreases, MC decreases, and the wood shrinks. This relationship is referred to as Equilibrium Moisture Content (EMC), and is accurately predicted.

Understanding Equilibrium Moisture Content

The moisture content of wood is tied directly to the relative humidity of the surrounding air. The higher the relative humidity, the higher the MC of the wood. Period. If youre installing wood thats recently been transported or installed on a job, it might take a little while for the material to reach its equilibrium moisture content (EMC) with the air in other words, for the wood to accommodate to the humidity level for the climate around the wood: the wood may take on more moisture or it may dry out. For example, if wood at 10% MC is exposed to 25% RH, the wood will dry to 5% MC (and shrink as it dries).

The EMC helps us understand the response wood will have to relative humidity, whether it will shrink or expand. For woodworkers and carpenters, the EMC is more helpful than RH. The simplified chart below shows the EMC values of wood when stored at the humidity and temperatures indicated.

Complete EMC levels for wood stored in unheated structures in your area of the country can be found at:

Equilibrium Moisture Content of Wood in Outdoor Locations

How Wood Moves

If the MC of the wood you install is too high, excessive shrinkage may occur, along with the risk of problems of unacceptable gaps and cracks in the wood itself. When the MC is too low, the wood may expand, and may buckle, bow, and distort surrounding material.

There are six key areas finish carpenters should be aware of when it comes to wood movement:

Width of Material

The wider the board, the more movement will occur (the term board technically refers to wood 1-1/2" thick or less, but for this article is used to refer to wood typically used by finish carpenters). It's a direct proportion: an 8" board will move twice as much as a 4" board, and a 12" board will move three times the amount as a 4" board. And it's important to keep in mind that a glued-up panel behaves basically as one wide piece of lumber.

Moisture Content of the Wood at Delivery

The only way to accurately predict wood movement is to know the MC of the material when you receive it. Moisture content is measured using a moisture meter. Failure to check your delivered material means you have no chance of anticipating movement problems. Further, material that measures outside of the acceptable MC level should be rejected.

Humidity Within the Structure Determines In-Service Movement Range

Homes in most of the U.S. that lack humidity control typically experience interior levels of humidity from 25% RH to 65% RH. This range of humidity will cause a 6% change in the MC of the wood. This change in MC will cause a 12" wide maple board to change 1/4". Exterior humidity levels range from 60% RH to 70% RH (lower in the SW, and higher near large bodies of water), and cause a 2% change in the MC of the wood. When material is installed that was delivered at an unacceptable MC, or the humidity range in the structure exceeds typical values, the amount of wood movement increases - and can cause problems even in well designed trim details. It's worth noting that panel material (plywood, MDF, composite materials) moves at about 1/10th the rate of solid wood.

Species Affects the Amount of Movement

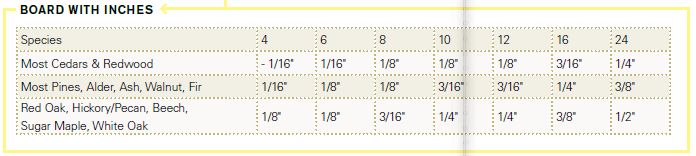

Knowledgeable carpenters realize that wood movement depends in part on the species. A 12" wide western red cedar board will fluctuate 1/8" while the same size maple board will fluctuate 1/4".

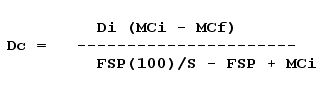

The formula for calculating wood movement is accurate, but tedious:

One simple rule of thumb serves as an approximate guide to predicting

wood movement: Most species of flat grain material will change size 1% for every 4% change in MC. Applying this formula to a situation where the seasonal EMC ranges from 6% to 10%, a 12-in. wide board will change dimension 1/8 in.

Below is a rough chart that offers approximate movement values for various widths and commonly used species of wood. These values are based on flat sawn lumber, and offer a general idea of anticipated annual in-service movement. The movement values for quarter sawn lumber are approximately 1/2 the flat sawn values.

If you want to know exactly how much the material youre using is going to shrink or expand, use this online shrinkage calculator. Simply enter the high and low MC values and the width and species of the board.

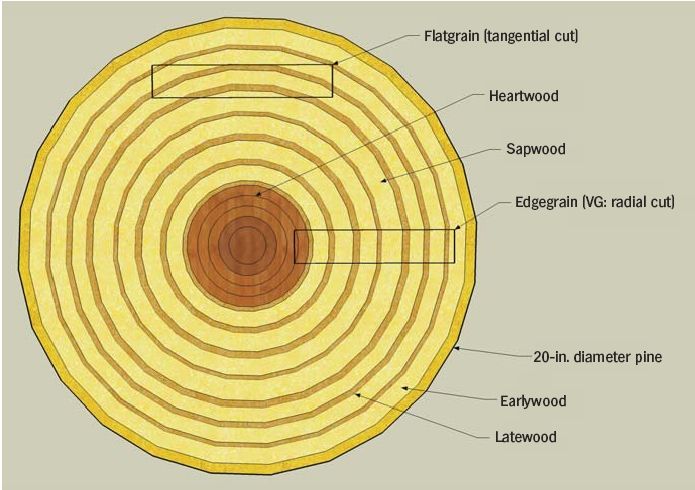

Grain Orientation Matters

Boards are characterized as being either flat sawn or quarter sawn. Quarter sawn lumber (also referred to as rift sawn or vertical grain) shrinks and expands roughly half as much as flat sawn. Most over the counter finish material is flat sawn, and you should assume flat sawn values unless you're sure your material is quarter sawn. Quarter sawn lumber has annular rings that are oriented between 45 and 90 degrees to the board's face. Flat sawn grain orientation falls between 0 and 45 degrees to the board's face.

Applied Finish Does Not Stop Movement

While it's true a high quality finish will slow the rate of moisture exchange, it will not stop it. Material finished on all surfaces will expand or contract at a slower rate then raw wood, but make no mistake - finished wood will eventually acclimate to EMC levels.

Events That Increase Movement Risks

There are many events that can contribute to excessive wood movement issues. Nearly all of them can be prevented before they cause a problem by measuring the MC of the wood as soon as it's delivered, and also by considering the in-service humidity swings of the structure. As soon as wood is delivered, it begins to acclimate to the surrounding environment. If wood movement becomes an issue, it's important that you document delivered MC so that site acclimation compromise the readings.

Excessive MC in delivered material

Optimum MC for interior millwork is 6-8%. In the real world, your material may arrive around 9-10%. For installations in unheated areas, the preferred readings are in the 12-14% range, assuming an area that is protected from the weather. In most cases, you can deal with material that's a couple of points high, but keep in mind that the wider the stock, the greater the movement. Ideally, wood movement should not exceed 2% when put in use.

Think through your trim details, and consider how they will react when the wider assemblies shrink. With wide glued up material, slightly higher MC levels may not be acceptable. If you'll be installing wide material, it's a good idea to be up front with your supplier and let them know that the material's MC must be within the range you specify.

Delivered material that's too dry

This is seldom an issue for interior trim, but can be a real issue for exterior trim. Material delivered at 6% MC, and installed outside, will acclimate at 12% in the more humid months, resulting in a 6 point MC change. This swelling of the material can cause significant problems in situations where installation creates accumulated movement (more on this later).

Long term storage of trim material

If you plan on storing trim material for any length of time in an unheated area, keep in mind that in most parts of the US, the material will acclimate to roughly 11-12% MC. This value is lower in SW parts of the country - a chart listing the monthly EMC values for your area can be found at:

If MC is too high, lower readings can be achieved by moving the material into a heated area. The amount will depend on the temperature and humidity of the storage area. The change in MC won't happen immediately, and the material in the center of a pile will change at a slower rate than the material at the edges. Spacing the material so all surfaces are exposed to the air helps, as does good air movement throughout the pile. You'll need to take sample readings with your moisture meter to determine when the material reaches your intended MC.

Higher temperatures result in a more rapid change in MC when the humidity remains constant (roughly speaking, moisture moves twice as quickly for every increase in temperature of 20 degrees). And despite what you may think, moisture gain or loss does not stop when temperatures fall below freezing. The moisture in wood is chemically bound in the walls of the wood cells and cannot freeze.

Typical on-site humidity

At certain points during construction, such as plastering or drywall, a tremendous amount of moisture is being added to the air, causing the humidity to spike as high as 80-85%. As framing lumber dries, it also increases the humidity at the job-site. If you are storing finish material on-site during these periods, be sure to keep them wrapped in a vapor impermeable material (plastic) with as few gaps as possible. Wood stored in this manner will not pick up any appreciable moisture.

Interior trim should not be installed until the temporary construction humidity has subsided. Use an accurate digital hygrometer to measure RH ($40). Generally speaking, interior trim should not be installed when the humidity is above 60%, or the material may climb above acceptable MC levels.

Humidity in unheated areas fluctuates about 10%, and while in service wood movement is low, dry material (6% MC to 8% MC) installed in unheated areas swells significantly. It's important that the MC of exterior trim be within 2-3 points of the EMC values for the area before it is installed.

In-service low humidity issues

In heating climates, older, drafty homes may see humidity drop to the low 20% RHs in the winter. The MC of trim and flooring in this environment will vary nearly 8%. Homes with wood stoves and no humidity control can see MC swings in the trim of up to 11% in areas near the wood stove. In extreme low humidity situations, consider using cabinet grade plywood for wide panel application instead of solid wood.

In-service high humidity issues

Typically, high humidity (constant levels above 60%) are not an issue. But if you find yourself working on a project that includes a room with a heated pool, proceed with caution. At 85% RH, trim will acclimate at 18% MC. A 12" wide piece of birch installed at 8% MC in that room will swell in width over 3/8". Letting your material acclimate to the high MC levels before installing is one approach, but keep in mind that if there is ever a period where the pool is drained for a significant period, and the humidity drops to typical levels, the trim material will experience severe shrinkage. A carefully worded disclaimer regarding wood movement would seem to be in order.

Understanding Accumulated Wood Movement

Glued up solid wood panels behave as though they were one wide board - a 24" wide panel will shrink and swell four times as much as a 6" board. But what about a series of boards installed side by side (T&G flooring, for example)? While it's true that each board can move independently, accumulated movement can cause significant problems, typically when the newly installed material gains moisture.

If the material in non-glued assemblies (flooring, for example) is installed "tight", and there's no gap to absorb expansion as the material gains moisture, the increase in width of each floor board becomes cumulative, and causes the entire floor to "grow" by the sum of each piece's individual movement. In cases of excessive shrinkage, unacceptable gaps can result between each floor board.

For example, random width oak flooring is delivered at 8% MC. The width of the room is 12 feet, and the floor acclimates to a high level of 11% MC, the cumulative movement is about 1-3/8". In the real world, a lot of this expansion is "lost" as the fit tightens up, and in some cases the wood fibers compress (this fiber compression can cause ridges to appear). But by using a moisture meter, and predicting the movement, you can decide whether you should install the material as tight as possible, or "loose" to absorb what you know will be an increase in material width.

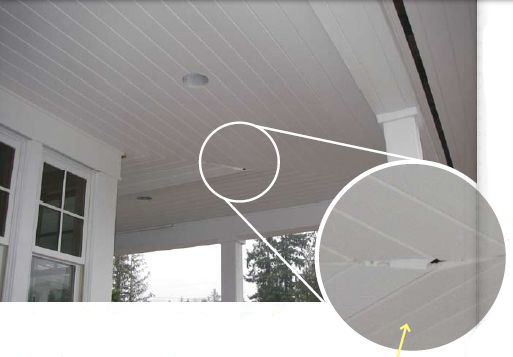

The porch ceilings below are examples of cumulative movement.

The moisture meter readings for the ceiling shown in the lower photo ranged between 12-15%, which is an expected EMC value for material installed in a protected but unheated location.

If the ceiling material (spruce 1x6 T&G) was delivered at 9% MC, the cumulative expansion for this 7 foot wide ceiling would be 1-3/8". Even if the fit of the each board accommodated 1/16" of this movement, there would still be enough expansion left (approx 3/8") to cause problems, including buckling, fastener withdrawal, etc.

Common Movement Issues

Paneled passage doors

Experienced door hangers know that a paneled passage door with a tight reveal in the winter will swell and possibly stick in the summer. But basing your door gap on the time of year you hang the door can be a mistake if you don't know the MC of the door.

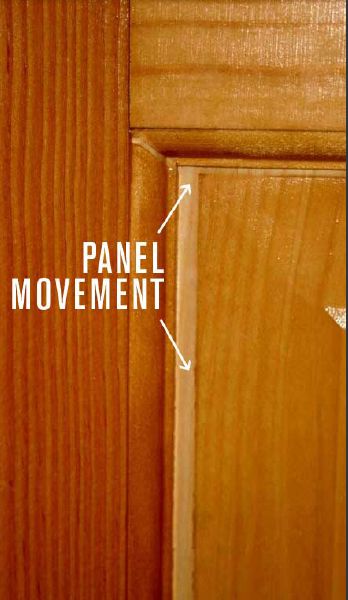

The seasonal width changes of a door are controlled by the MC change in the door's stiles.

If that fir door you're getting ready to hang in the winter has been stored for 6 months in an unheated building, the MC of the 5" stiles may easily measure 12-13%. After that door is hung, the MC of those stiles will drop to 6%, and the door can easily shrink 3/16". Your tendency to hang that "winter" door loose will be a mistake, because it's going to shrink even further after it acclimates.

And keep in mind that the door panels in this example will shrink significantly after installation. This won't effect the fit of the door, but if the door finish is applied at the MC noted, there will likely be unfinished wood exposed as the door panels shrink to their in service width. This is particularly noticeable when a light wood is stained dark.

By measuring the MC of the door stiles, you can base your door gap on established movement values, not guesswork, and avoid call backs when the fit becomes a problem.

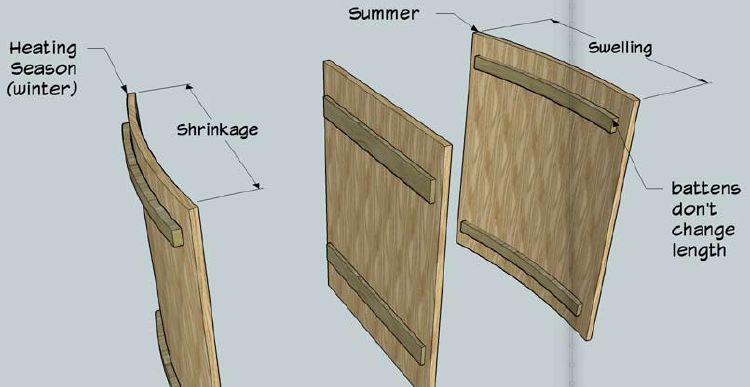

Doors with horizontal lines

Unless you're set up to build these doors properly, avoid them. The typical horizontal batten door is built using T&G material for the door face, and then battens are fastened to the back of the door to hold things in place. As the seasonal MC of the T&G material rises and falls, the boards expand and contract, and the door will cup inward or outward depending on the direction of the movement.

Kerfs absorb seasonal wood movement. This is one method used for cabinet batten doors that successfully allows for seasonal wood movement.

Captive panels

Resist the temptation to "picture frame" a solid wood panel. The miter joint will always fail when the panel expands and contracts. Instead, use a breadboard nosing design so that the wide panel can shrink or swell without destroying the surrounding joinery.

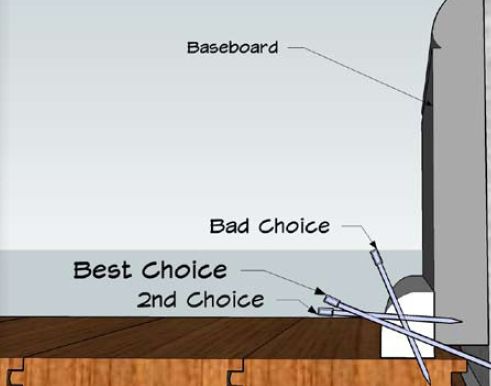

Inside corner trim

When installing trim that covers an inside corner, fasten the trim through the corner and into the substrate so the adjoining finish material can move independently as its MC changes. A typical example is base shoe moulding. If you fasten it to the baseboard, it will lift off the floor as the base shrinks.

Common Myths

Wood is stable at below freezing temperatures.

The moisture in wood is chemically bound in the walls of the wood cells and cannot freeze, and expansion and contraction continues at below freezing temperatures. Wood does acclimate more slowly at lower temperatures.

Wood will expand on warmer days, and contract on colder days.

For all practical purposes, thermal expansion and contraction of wood is not an issue. That said, warmer temperatures speed the exchange of moisture within the wood. Moisture exchange will happen more rapidly at warmer temperatures, but there is no thermal movement of wood worth measuring.

It doesn't matter if lumber is kiln dried.

Kiln dried hardwood lumber typically leaves the kiln near 6% MC (softwoods at 10-12%). But all kiln dried material will acclimate to the surrounding EMC levels. The significant advantages of kiln dried material is that it is typically heated to at least 130 degrees in the kiln, which will stop any insect activity, and also "set" the sap in resinous softwoods (sap in resinous air dried material can bleed from the board after it's installed, especially when interior temperatures rise in the summer).

They don't make wood like they used to.

It's true that most of the old growth timber is gone, but properly dried vertical grain material has highly desirable movement characteristics. If you're seeking material that will move the least, choose one of the more stable species, and specify vertical grain (and be sure to check your wallet before ordering).

Moisture Meters and Their Use

Owning and using a moisture meter is an inexpensive way for finish carpenters to predict and avoid wood movement problems that could require costly repairs.

Two types of moisture meters are suitable for finish carpenters: pin-type and pinless. Both types measure the electrical properties of the wood, use the electrical values to determine the MC of the wood, and can be purchased for around $200.00.

With pin-type meters, their needle like pins are driven into the wood, and the MC is calculated based on the measured electrical resistance. Non-pin meters typically have a sensor plate that projects an electric field when placed on the wood surface (a flat surface is required), and offer a measurement range a few points lower (30%-4% MC) than pin-types (30%-7%). Non-pin meters display average MC readings of a board's cross-section - up to about 2 inches thick. With both types, there will be natural variation in the readings, but this variation is typically well within acceptable ranges.

Detailed instructions are included with the purchase of a moisture meter. Typically, temperature corrections are made when the material is below 50 degrees, and slight MC corrections are made based on the species being tested. Wood surfaces must be dry, free of any moisture when testing (rain, snow, ice, beer, etc.).

If material is delivered a few points below the low end of the target range, the dimensional expansion - particularly wide material - will likely cause problems. This event is rare for interior material with a target range of 6-8% MC. Pin-type meters are accurate down to 7%, non-pin meters down to 4%, so it's difficult, if not impossible, to recognize overly dry material below these levels. If a delivery of interior finish material consistently measures at the lowest reading for the meter, it may make sense to learn more about environment where the material was stored prior to delivery. Since the target range for material used in unheated areas is higher (12-14% MC), overly dry material can be easily recognized when metering.

Which meter is best? Non-pin meters don't work as well with woods under 1" thick, and the sensor plate needs to contact at least one square inch of wood surface (which can be tricky when testing a molded profile). Pin-type meters do a better job reading isolated areas, but leave pin marks. Either meter will provide the needed readings, but I'd recommend the pin-type since finish carpenters often work with moulded profiles and materials that are less then 1" thick. The ideal is to have and use both.

Carl Hagstrom is the Systems Administrator at WOODWEB.com, and a

contributing editor at The Journal of Light Construction. Many thanks

to Gene Wengert, Professor Emeritus at the University of Wisconsin,

who has written extensively about wood movement during his many years

of participation at WOODWEB.