Question

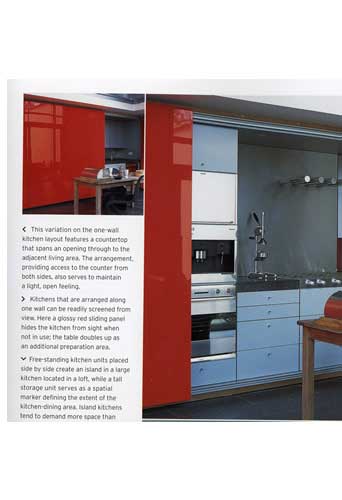

I have a number of questions and need some advice on getting started with a project. I want to make a high gloss panel that is similar to the one in the image below. I am planning on using high quality plywood for the basic material, and then finish to a high gloss covering. The finishing I am thinking of would consist of priming, and painting which I would then finish with a polyurethane clear gloss.

I would like advice on material choices - is there something better than using plywood? Also I would like some insight into the steps needed to create the finish in the image. For example is lacquering a better approach?

Product advice would be of great help as well as equipment. I have looked through the forums, and have done some research in books on woodwork finishes but nothing came close to giving me advice on creating a high gloss finish over a painted medium on such a large flat surface.

Forum Responses

(Finishing Forum)

From contributor J:

Although I use plywood on almost all of my cabinet jobs I think I would be careful in this situation. MDF would be much flatter and also easier to get a good finish on. If the panel is going to be firmly attached to something which will keep it flat you may be ok but you will need quite a few coats of primer and/or pore filler to get a flat surface.

Another option could be to laminate a thin sheet of 1/8" hardboard to the plywood for a very smooth surface. Also with either material you will have to make the edges smooth. I think I would probably not use edging as this could swell/shrink over time under the paint.

As for actual painting I will just throw out one possibility. I use ML Campbell water-based lacquer primer for my paint grade projects and it is very easy to work with. You may also want to look on the car restoration sites. Those guys have a lot of knowledge on getting perfect painted finishes.