Accurate Resawing with the Bandsaw

Tips for scribing or kerfing wood in order to keep bandsaw cuts precise and accurate. December 14, 2009

Question

I'm setting up a Jet 18" bandsaw. I've put on a new 1/2" blade, tensioned according to Jet, all of the guides are right, and the fence is parallel to the miter gauge slot. I'm resawing a poplar board 3' thick and 9" wide into 1 1/4" wide by 3" thick boards. The board keeps creeping away from the fence and I can't keep it tight to achieve a constant thickness through the 8" length. I'm using roller stands to support the outfeed end of the board but believe it to be level with and parallel to the table on the saw. Where am I going wrong? This is so frustrating!

Forum Responses

(Furniture Making Forum)

From contributor J:

You're going wrong by setting the fence parallel to the miter slot. It's normal for bandsaw blades to want to cut a line a few degrees one way or the other from the line you'd expect; the phenomenon is known as "drift."

Instead of setting the fence relative to the table, set it according to how the blade actually cuts. Gauge a line onto a stick of scrap wood, and cut alongside that line (freehand) until you're about halfway through the length of the piece. Make a couple of marks (pencil, tape, etc.) on the table to record the precise orientation of the scrap piece of wood, then set the fence angle to those marks.

From contributor B:

Blades wander - that is the nature of bandsaws. A better fence is a semicircle that allows the sawyer to compensate for blade wander and hold the cut to the line. Trying to use a flat fence will create a lot of waste.

From the original questioner:

Thanks, contributor J! That did the trick, or at least I know which direction to go. I've just learned that the Jet fence isn't worth a d@#$ and that I need a better one, or more adjustable one at least. Any recommendations?

From contributor W:

I have the same Jet 18" saw. There should have been a heavy duty steel bar that can be bolted to the fence. It works okay for the times I have needed to resaw (a rare event). There are two options -

Rockler (I think) has an elegant resaw fence with the curved face, or make a tall point fence and clamp it to the table. In all cases, set the nearest point of the fence to be at or just in front of the cutting edge of the blade.

From contributor R:

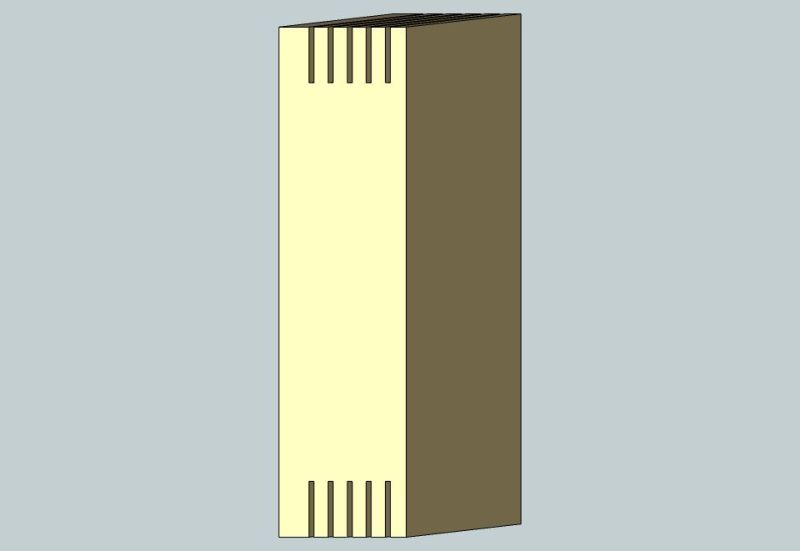

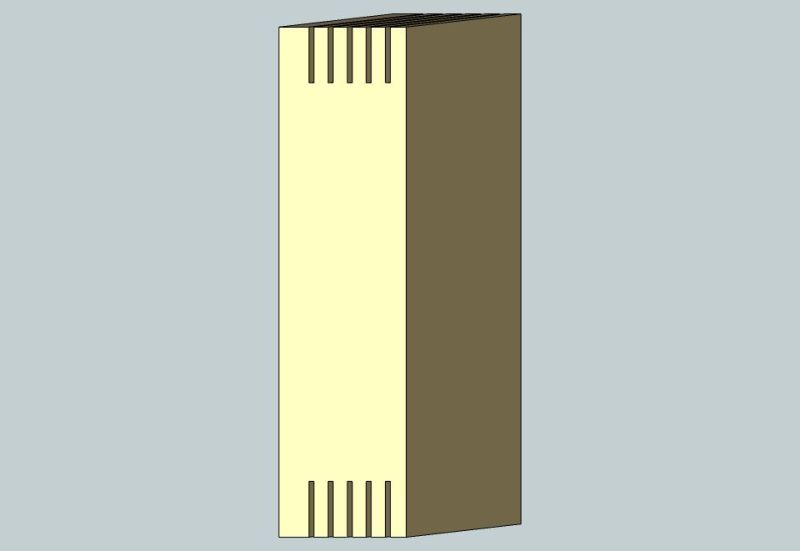

A good technique for most re-saw work is to ditch the fence and guides altogether. Take your stock to the table saw and flipping the board to keep the same face fenced, kerf it top and bottom a comfortable depth, cut a pair for every piece the stock allows. This is very fast - much quicker than scribing lines. Then simply freehand the board through the bandsaw using the center of the kerf as a guide. As the bandsaw blade will naturally want to take the path of least resistance, it is also somewhat “self guiding” and the blade will not be prone to wander out the path at the bottom if pushed too hard or if it is a bit dull. I would also recommend a blade sold by Hiland Hardware called the Wood Slicer - it is the most free cutting and straight tracking blade I have found.

Click here for higher quality, full size image

From contributor O:

I agree completely with contributor J - it is your fence set up because of the drift. I just get to the end results a little different. Use whatever is best for you. I set up my fence then take a scrap board and run it through the saw as contributor J said, maybe halfway. Then look and see if the blade is tight against one side of the board, and if so, move the fence in the direction needed to center the blade in the cut. You should have an equal space on both sides, or as close as you can get. You should be able to do what you want with no problem.

The comments below were added after this Forum discussion was archived as a Knowledge Base article (add your comment).

Comment from contributor A:

Once you start a rip cut and establish a kerf, the blade itself has a direction of travel in the same sense that the fence does. The fence won't guide you where you want to go if the blade is pointed in another direction. The correct procedure is to get the blade and the fence going in the same direction; by whatever means. It doesn't matter how you do it; align the fence, re-orient the table, or re-track the wheels; it's all the same and whatever's easiest is ok. Incorporating extra cuts with other shop tools is going in the wrong direction and only serves to prolong the problem and add unnecessary complications. In the time it takes to set up a point fence you could most likely have determined which direction your blade is headed and pointed your fence in the same direction. It's that simple. If you're going to use a tablesaw, why not just turn the board over and cut it from both sides? (If they don't meet in the middle, you've got a tablesaw adjustment problem as well, and I'd attend to that problem too).