Question

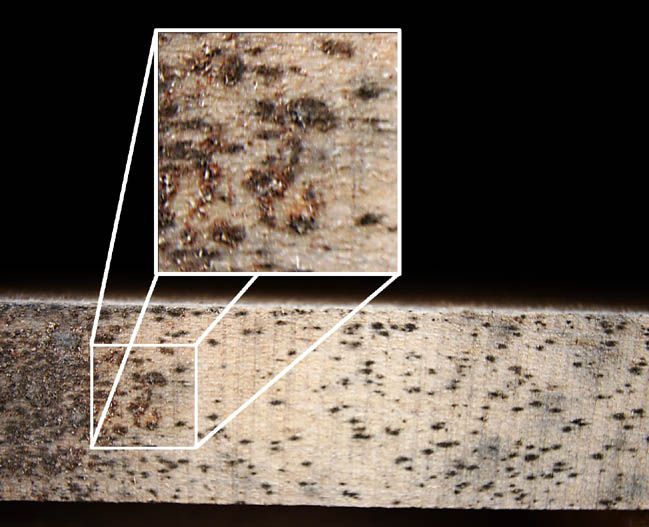

I have 3000 BF of white oak, pecan, sweet gum and pine air drying in SW Arkansas. Within the last four weeks, a blue-black mold has attacked all of the hardwoods, but not the pine. It seems to be confined to the outer edges of the stack. I noticed the bottom two rows of one stack are 2” inside the rows above, and have no signs of the mold.

Trees were cut mid-October 2011 and milled into lumber the first week of December. The weather has been cool and humid with rain approximately every two weeks. The stacks are 20” off the ground, and are covered with an overhang of approximately 10”. The oak and pecan stacks are protected with 50% shade-screen all around.

I have read everything I could find on this forum, and Dr. Wengert’s many publications. But now that I’m stuck with this problem, I am not sure what to do. I would really appreciate any advice.

1. Is this blue mold, or something else?

2. What is it likely to do to the lumber? Is there any hope to mill off the affected areas?

3. From what I’ve read, it seems impractical, ineffective and dangerous to chemically treat the wood now. Is there any other method available to treat the mold?

Location: SW Arkansas

Date Cut: 05 Dec 2011

Mold appeared: 10 to 12 weeks after being stacked.

Depth of mold discoloration as of 19 Mar 2012: approx. 1/32"

Forum Responses

(Sawing and Drying Forum)

From Professor Gene Wengert, forum technical advisor:

I would guess that low air flow and high humidity are combining to create conditions for mold growth. Perhaps that row of trees on one side is a bit too much restriction on air flow. Otherwise, the way you are stacking is great. I assume you are using 3/4" stickers. I cannot tell your pile width, but is it 5'?

The mold can indeed get into the wood and cause inside color problems. The issue here is what is ideal for mold is also ideal for other color loss fungi and chemical stains. So, faster drying is the solution. Maybe you will have to get some portable fans if natural air flow is poor.

Would you recommend removing the shade cloth on the two stacks of oak and pecan? Perhaps that would improve the air flow through the stacks. After being stacked for 12 weeks, my MC meter shows over 30+% in all the hardwoods, and 16% in the pine.

While the current weather is solid rain (estimating 5”-6” before it stops) it should warm steadily in the next few weeks into the 80s, with lowering humidity. If these improving conditions are not enough to arrest the mold, perhaps I should find a kiln and have it dried right away.

Did I err by cutting so late in the autumn?