Attaching 3/4-Inch Plywood Cabinet Backs

Cabinetmakers describe alternative ways of fastening cabinet backs to carcases. April 9, 2008

Question

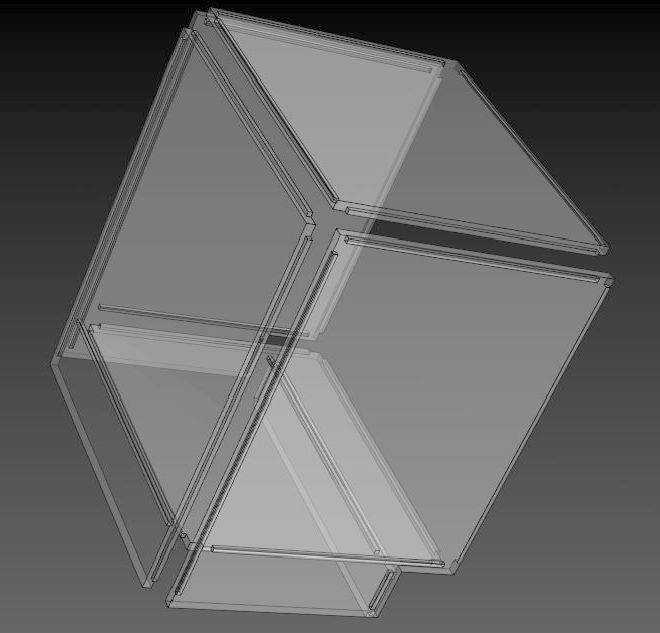

Our regular backs are 1/4 sheet stock, but we've got a job that requires all-ply boxes with 3/4 thickness all around. Carcass parts are CNC cut, and we like and are used to blind dado joinery. All cabs have applied ends, so cab sides cannot be seen. Wall cabs get skins under, so nothing is seen there either.

Here is a first cut at the way we might do them. All four sides are joined, then the back is applied and screwed on. All four joints are blind dado. Is there a more preferred way?

Click here for higher quality, full size image

Forum Responses

(Cabinetmaking Forum)

From contributor P:

Nice, sturdy design, and very sleek appearance to be sure, but wouldn't the back be better off set into the boxes and through-fastened with screws or staples and glue through the gable sides, tops and bottoms? Then you would only have to use the veneer overlay on the exposed gables and I'm sure the cabs would be less likely to come apart from the weight of years of overloading.

From contributor D:

Why not set the back into the box and blind dado into the sides, top and bottom?

From contributor B:

I know you said you're a dado guy... What about pocket screws? Cut the decks, tops, and backs the same width, pocket from the back, top and bottom, and pocket screw the face frame on from the sides, since they get covered. Just a thought. If it's a one-off job that might be somewhat small, you can go buy a Kregg jig and have at it. If you don't like pockets, just screw through the end panels and cover.

From contributor K:

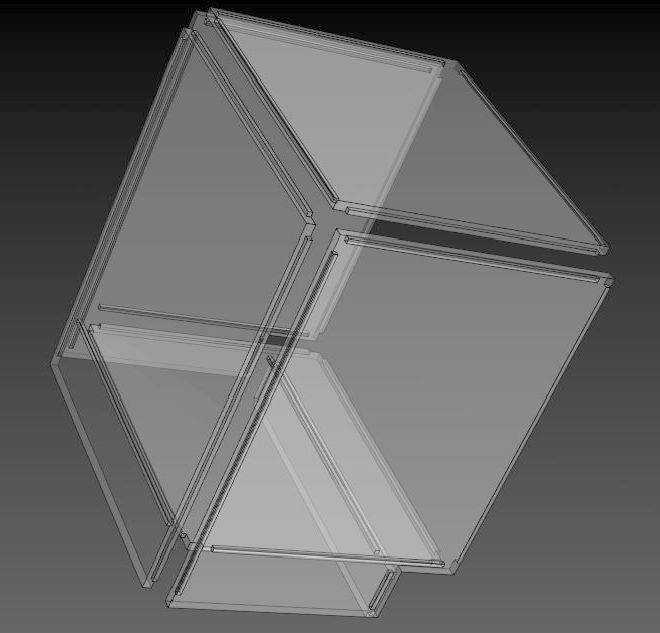

I would capture the back with the sides and top using blind dado instead of planting the back on. It makes a better box and if for some reason you don't have an applied end (say a tall cabinet exposed on the countertop side), you won't have the edge showing

Click here for higher quality, full size image

From contributor N:

Compromise. Make a very shallow dado. Inset the back and pocket screw from the back for strength. The shallow (1/8") dado will hide the joint in case it is not perfect. Nothing ever is. Always another way to skin that cat, huh?

From contributor V:

Cut a 1/4" deep by 1/2" wide dado 1/2" in from the back edge of the sides, tops, and bottoms. Cut a 1/4" deep by 5/16" wide rabbet on the back side of the backs. This allows you to capture the 3/4" backs inset 1/4" from the back edges of the boxwork (allows 1/4" of scribe if needed) and the 1/2" inset of the dados is more solid than the 1/4" that would occur if you cut 3/4" dados inset 1/4". If you typically use 1/4" backs they are probably captured in a 1/4" dado inset 3/4" from the back edge of the boxwork allowing for 3/4" thick hangstrips. By cutting a 1/2" dado inset 1/2" your boxwork depth inside will be the same as it is with your 1/4" backs. For added strength you can place a bead of hot glue around the perimeter of the backs.

From contributor A:

You definitely want to capture the backs in a dado, especially if the 3/4 back serves as your nailer. I wouldn't trust anything else, especially for wall hung cabinets. I'd pocket the back in, too. Be sure you use shorter screws!

From contributor B:

Just went to the Atlanta Woodworking show today and the Sommerfeld guy was there showing off his dado cabinet system. You should check it out... pretty good system. Does it all with dado router bits.

From contributor U:

I use all 3/4" backs. They are the same height as the cabinet (decks cut short) and mount between the end panels (same width as the decks). I use comformat screws. Way strong, way easy, no dados!