Bandmilling short logs safely

Other Versions

Spanish

Some ideas for cutting short logs on bandmills. March 21, 2002

Question

Many times I get nice compressed stump sections or crotches that are less than 4 feet that I'd like to cut on my bandsaw mill, but I've been told it's very difficult to cut these lengths. Is this true?

Forum Responses

Yes, it is true, but I do this on my WM by using a combination of manual dogs and a jig to keep it from falling through the deck. You must be careful, as dogging short pieces can be dangerous and break equipment if it gets loose. Most of my short stuff is at the request of bowl turners, who find a lot of their wood in the firewood pile.

I set up something similar to a clamp. I use 2 3x8x8 and center the log. I notch 2 corners in the bottom of the log about 4 inches wide, 3 inches deep. Then the log will sort of match together like a cradle on the 2 3x8's. Then I clamp the 3x8s together. It would be a little trickier with a crotch, but I wouldn't be afraid to try it. Just be careful and make sure it is clamped tight.

I lay a 2" thick board on top of the deck for the short to lay on. Then I stand a scrap up between the short and the log stops and dog it into place. If the short doesn't have a flat side on it, I turn it 90 degrees after the first cut so it will rest against the scrap. I then flat saw the log, usually turning it over about half way through and lowering my dog. I just saw through the scrap with the short.

From contributor A:

I am glad to hear that I am not alone in the re-sawing-of-firewood market. I have been asked to saw as short as 14 inches. I charge them by the hour and they could get better wood for the money from my stash, but it has to be from that piece of wood they saved from the fire. But 34 inches chucks in my mill fine and I saw away.

Contributor A, don't you use a WM? I have a local sawyer that has a WM LT40SH and he tells me that anything less than 48" can't be done. What setup do you use to saw shorter pieces with your WM?

A 36" piece will catch the 2 manual legs and I just chuck it in. Others I set on a scrap 1x4 and put a scrap 2x4 for a backer on the manual legs. It is no real trick but a lot of guys will not mess with you. A few I have never seen again but most become very good customers. And I really like them because they have a love for wood.

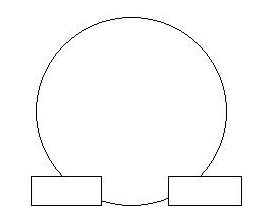

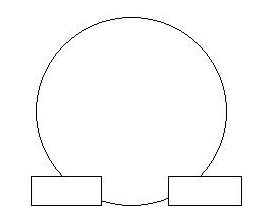

Here is a shot of a plywood table I add to my WM to cut odd shaped or short wood. This shot shows me cutting 22 1/2 degree posts for a deck.

I often cut stuff that is shorter than my two center rails on the HD40. I just use whatever scraps are lying around and so far haven't lost one. I charge by the hour, too.

From contributor A:

I've sawn a few 16" lengths of firewood on my T.A. Schmidt - advantage of movable bunks. Takes about 10 minutes to change. In this situation, however, there's not any real weight holding the wood down, so it's all up to how tight the dogs can be clamped.

Editor's Note: T-Tool (website) supplies quality CNC tool holders and accessories, including collet chucks, milling arbors and drill chucks.