Question (WOODWEB Member) :

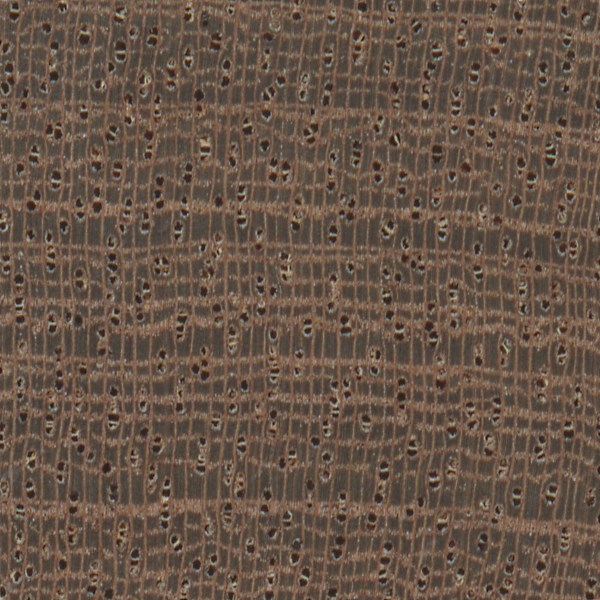

Iím curious if anyone is using a Brush Sander (such as Quickwood) and what grit you might be using on hard woods such as maple? I am sanding to 180g on a widebelt then through the Quickwood at 150g but the Quickwood 150g is leaving noticeable scratches which show up when stained.

Forum Responses

(Finishing Forum)

From Contributor W:

I worked in the brush sanding industry for the last eight years. What type of brushes do you have on your Quickwood? Are they Quickwood brand aluminum cores with Quickwood brushes and separate replaceable sand paper slashes? Is the paper black? The scratches are perfectly normal with new brushes. The scratches you get from a brush machine are entirely different than what comes from a wide belt sander. You need to break in the brushes to start. Put a bunch of scrap doors in the machine and set the machine height just high enough for the support brush (the yellow Tampico). Drop the height down another 8 to 10mm or 5/16 to 3/8" lower than the surface. Run the machine at 300 rpm for three hours. After this initial break in you will see a huge improvement, but more might be necessary.

For production, run the height of the support brush about 3/8" above the conveyor at the slowest rpm the hubs can be set, usually about 200 rpm. The carousel rotation is your only means of consistency. Look at the edge break all around and increase/decrease the carousel speed to get the most consistent edge break possible. It will usually be pretty slow. If the corners trailing the direction of the carousel travel are not as broken as the lead corners, slow the carousel down a bit.

As far as polishing, if the part isn't over polished going in, it won't be coming out if you run the machine as I described in my earlier post. The trick is slow head speed combined with a nicely open part going in. In Salt Lake City I fixed a color issue with a Slipcon brush sander by merely changing the first sanding head in the wide belt from a 120 grit to a 100 grit.

Also note that even an unbroken 320 grit will leave scratches that show in the stain. No matter the grit you use you will need break-in of some sort.