Building a sawmill shed

Tips and designs for building a sawmill shed

Q.

I am planning to build a shed to store and operate my Enercraft 30M in and am looking for design ideas and suggestions.

Forum Responses

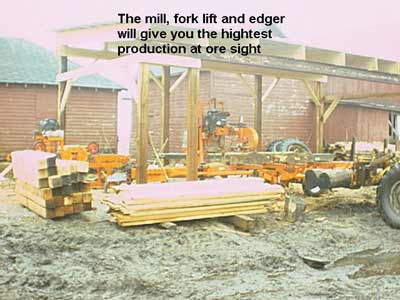

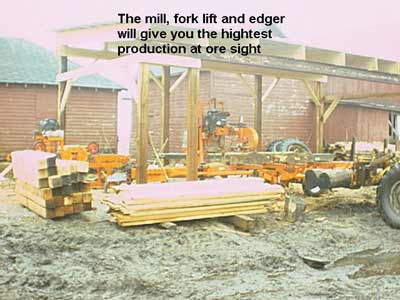

Here is a picture of my set up with my Peterson and lt15 52’ x 27’, a great place to dry the lumber. I winch the logs in with a capstan winch, thus no log brow. I pipe out the exhaust, and in the summer the end plastic comes off and the sides roll up four feet.

I’m including a couple of other pictures showing some alternative ways to deal with logs.

I have my Enercraft 30Mset up in a shed with a 100 ft long log deck. I fill the log deck with logs during the winter. It holds about 800, and then I saw part-time throughout the spring summer and fall. My shed is 22 ft long by 12 ft wide, and mill sets to the side. The log door is 14 ft wide by 4 ft high.

From contributor M:

I made a mill shed from the wood from my Woodmizer mill. I used a I beam to span the 21'opening for the logs. I left all the sides open for now, until I decide where the walls and doors should be.

From contributor O:

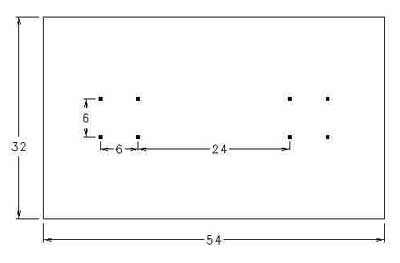

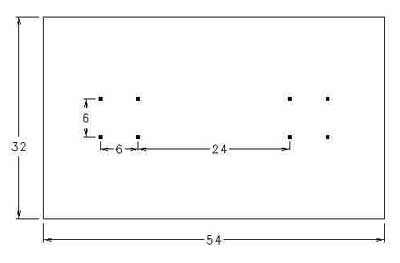

I am in the process of building my saw mill house at this time. I came up with a design that will allow me to move around the mill so that I could load/off-bear from both sides and not have to dodge post. It is 32 x 54 ft with 12 ft clearance overhead. All of my sides are open because here in north Arkansas, winter is not a problem. There are 8 upright posts of 6 x 6 x 18' white oak set in groups of 4, 6 feet square 24 feet apart (2 feet set down in concrete). The cross members are 3 x 8 white oaks 24 and 16 feet long that make up the upper frame work. The rafters are 2 x 6 pine on 4' spacing and the nailers for the tin are 2 x 4 pine.The pitch would be flat for in a snowy area. It is open so that I can drive in and out and store logs under the roof.

To contributor O:

Is this how your posts are arranged in relation to the size of your roof? Dimensions are to centerlines of the posts. Is this correct?

How are the other major structural members placed? I can't come up with a combination to use the 3 x 8’s that would result in a 32 x 54 unless the 2 x 6 rafters overhang and make up the total width and depth.

From contributor O:

Yes, you are right. The two 16 footers and the 24 footer are notched so that a foot is lost at each one. The difference is made up in the first rafter on each end. The 3 x 8's are cut into the 6 x 6's at 12 ft and at the top of the post. The bottom of the rafters sit across the top of the 12 ft 3 x 8's and the top of the rafters sit on top of the top 3 x 8's. There are X braces from the top 3 x 8's to the bottom 3 x 8's and 6 ft cross braces.