Question

I am considering building a slab saw to chop bundles of kindling. I have a 10 hp tefc saw-arbor motor, a #2 starter, and a semi-auto plastic strapper.

The trouble is, I've never seen one before so I don't know how to proceed. Does the saw move or the slab(s)? Conveyer to advance the slab? Is some sort of clamp for the wood required?

My slabs are typically small softwood (larch).

Forum Responses

I have a Rainier hydraulics chomper that uses a shear to cut firewood. I bought it to process slabs, and it does a fine job. Now if I could just get more customers. I think your desire to bundle is probably going to give you a more marketable product.

I made three sawhorses and a table that looks like a ladder without round steps. I used 2x4 oak for the runners and cross blocks. These cross blocks were added directly onto the runners. The spacing was 2' on center. On top of these cross blocks I mounted a roller. I got 7 or 8 of these at the local woodworking tool and supply store for about $6.95 to $9.95.

Next I built a special bracket stand to hold a chain saw lumber maker. You know, one of those things that you clamp onto your chain saw bar and slide down a 2x6 to rip logs into lumber. I mounted that to this special stand and at an angle to hold the saw up out of the way when not cutting slab. Then I added a fence to the front edge of the table to stop the wood from sliding off as being cut, as the chain saw would pull the wood towards the operator. To the top edge of this fence I pounded in roofing nails with the heads spaced out 16" from the chain saw bar.

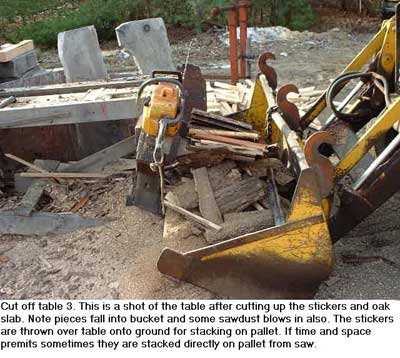

To use this cut off table, I would drop a piece of slab onto the table, slide it over under the chain saw bar until the opposite end lined up on a nail head. Then cut off a piece shorter than 16". This waste piece would drop into my backhoe bucket. Then slide, cut and drop. When the bucket is full, it's dumped directly into the dump truck for hauling away.

I'm lucky to have a bark mulch guy near me who has a tub grinder and will take my entire slab, with no disposal fee. But he doesn't want long lengths. Now he will take four to six footers. I only use the cut off table to cut hardwoods to save for my own stove or to sell.

The total cost was under $100 for rollers and chain saw lumber maker. I had the lumber for the saw horses, stand and table.

Make it safe for anyone to use.

I was thinking of some kind of adjustable stop for piece length that would retract as the saw engages. A table on the out-feed side to support the pieces, and a little rack to slide them into that would hold them for bundling.

My slabs are tiny so I think I'd stack a few on there before cutting the length. This, I think, means I will need a hold-down of some kind. A 3" nylon strap and spring over the slabs next to the saw, I think. A foot pedal could bring the strap down as well as the length stop.

Another thing I need to watch for is keeping sawdust and bark flakes out of the guts of the strapping machine. This might be the limiting factor for my plans.

An out-feed table or bundling station would work for you. You'll have to make one up and try it. I use a plastic strap on my grade stakes and it works well with a little metal buckle. This could be something you could use to hold your bundles together. Then you might need a handle of some sort.

Below is another shot of the table with the saw and backhoe bucket.

Each bundle goes for $5, which is equal to 22 bundles per rik, 66 per cord and $330 a cord. I move up to 10 cord a year if I want to, otherwise the small stuff goes into the chipper and I sell the chips for $10 yd delivered or $8.00 yd u-haul.

The larger slab wood goes into a jig that holds 1/4 cord of the material and is designed to be picked up with forms and dumped into my truck for delivery. The jig is designed so that I can cut it every 16" or 32" depending on the customer. I use most of the material myself for heating my kiln with a Taylor Stove or for the house, which is also heated with a Taylor.