CNC V-grooving

Suggestions for tooling and techniques. March 23, 2002

Q.

Is anybody doing any kind of v-grooving with their CNC machine? What kind of tooling are you using?

Forum Responses

We're making beadboard using a saw blade on our aggregate. Works great.

At Howard Miller we are using 4 diamond router bits supplied by Active. They work great.

Diamond file off the tip of the insert and that will clean up any fuzzies left at the bottom of the cut.

From contributor M:

For decorative V-grooving .09" or less deep, I use a V-groove saw blade in my aggregate. For mitre fold cuts or lettering, I just use a Leuco insert tool body with neutral pressure inserts. So far, I have been very happy with the results. I haven't yet tried to V-groove solid surface with anything. Does anyone have a tool they recommend for Corian and the like?

From contributor K:

Are you folding? Using vinyl or using tape?

From contributor M:

I don't mitre fold on a production basis, but the last job I did for a large lobby involved making column covers out of maple veneer with 3/4" MDF core. These covers were 78" high with either one or two returns. I removed all the material except for .015" of veneer. Just to be sure that the veneer did not crack, I applied pressure sensitive tape to the face of the veneer before machining. Saved tons of time by having our custom guys just assemble them rather than fabricate them from scratch.

There are a variety of tools you can use. To get a true point on a router bit, only an insert tool will do the job. A brazed tool will have a flat of about 8 thousands. If you have an aggregate head, a saw blade with the angle will work. But if you are required to mitrefold 3/4"+, weight becomes a problem. Usually no more then 8 pounds are recommended. You can then use a non-ferrous type insert body to do the V-groove, or remove as much weight of a carbide or diamond tool body.

From contributor K:

We have a saw that will run either X or Y direction. The parts can be made from 1/2".

Contributor K, what machine and model are you using? Are you using an aggregate or dedicated head? What is the maximum blade size and what materials are you cutting?

From contributor K:

We have a new Rover 27 with a 10kw router and a 4HP saw. I think the max diameter blade is either 160 or 180.

From contributor A:

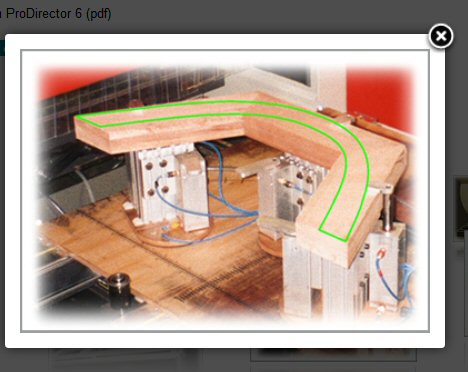

We V-groove on our p2p with a horizontal planing aggregate - we use a 100mm x 100mm cutter on the aggregate - we have diamond and carbide with insert tooling. We do all types of materials, from MDF to solid surface. We also do coved splases for solid surface, and try to do any "L" or "U" shape as a fold if we can. We just ran about a mile of p-lam tops with a 3" drop and about a mile+ of 5" wall cap with a drop edge. Solid surface is great as the glue joint ends up concealed. If you have a lot of volume, I would look at a feed through machine.

Contributor A, are you mitre folding the front edge of the top with p-lam already installed? If so, don't you have problems with the architect's specs, where they insist that the p-lam edge not be mitred? Also, don't you end up with a sharp and weak edge? I think that this is a wonderful thing if it can work but I have always thought it too scary to try.

From contributor A:

WIC custom grade allows the edge to be before or after the top is laminated, which allows us to use prebonded panels. We detail it as a mitered joint and you need to file it so it isn't sharp. We did the v-groove, draw bolts and grommets all on the p2p at one time. There were about 130 "U" shaped workstations, all different sizes. We have been doing this detail for close to 11 years when we have drop aprons.

We just started using a v-groove blade on our BP140. We kept the saw blade the same size and specs as our X-grooving saw, so all we have to do is swap blades (the machine doesn't know the difference). Actually, we just tried a dbl v-groove saw blade and it works great as well, and we've tried everything.

We machine small 1/4" panels with moderate success, but 1/2" or thicker works best. I am supposed to run 1/4"x4'x8' sheets but I haven't found a good way to hold it down. P2P is the wrong machine for the job, if you ask me.