Cabinet Back Strategies for CNC

A discussion with drawings of ways to machine cabinet backs and sides for convenient and strong assembly. May 15, 2011

Question

We'll be receiving our first CNC router in a couple of weeks. I'm planning on blind dados for tops and bottoms, but I'm wondering what the prevailing opinion is on cabinet backs. I'm interested to know what thickness material you're using, what joinery, and if you are using nailers. If yes to nailers, how are you building them?

Forum Responses

(Cabinetmaking Forum)

From contributor M:

Seems obvious to me... Dados. Your main choice is whether or not to cut the top short so the back can slide in after the case is assembled. As for the nailers, I do not use them except on very tall pieces (>1200mm). If you glue in the back, the nailer adds little in the way of strength - the dados should be plenty. For hanging wall cabs you might want the nailer; I use Euro cabinet hangers. I prefer the nailer on the back of the back, but that means the back is inset 3/4".

From contributor D:

As you say, blind dado top and bottom, inset back dado left and right, top and bottom screwed through. Material either 16mm or 18mm melamine. Too easy (nobody uses plywood in Australia anymore, except in specialised applications).

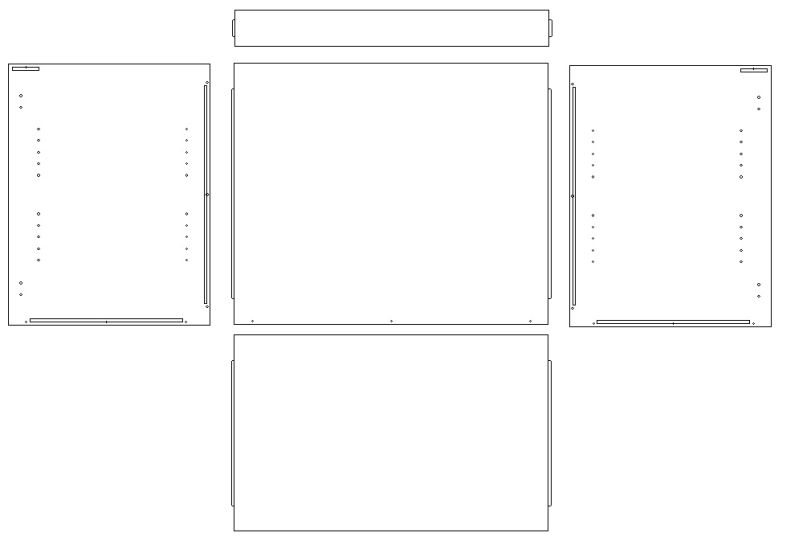

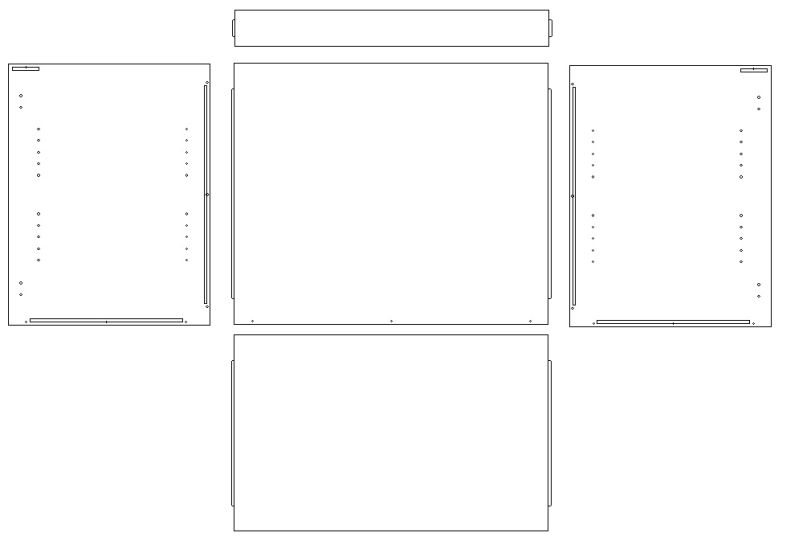

Click here for higher quality, full size image

From contributor K:

I will be using 5/8" plywood backs with barbed dadoes, no nailers.

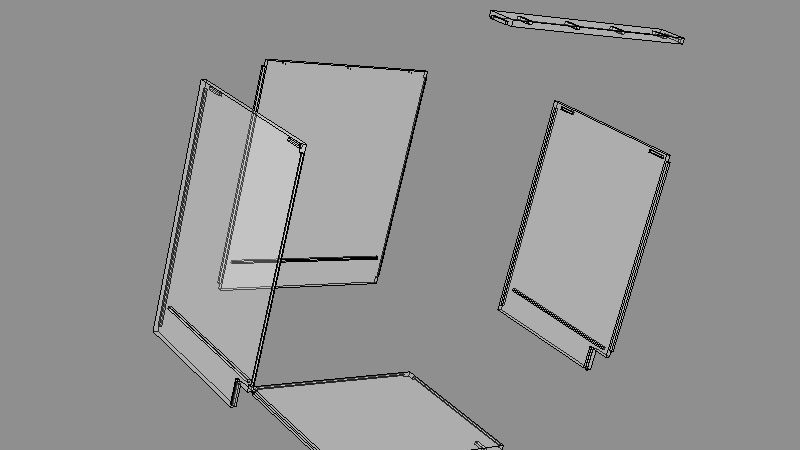

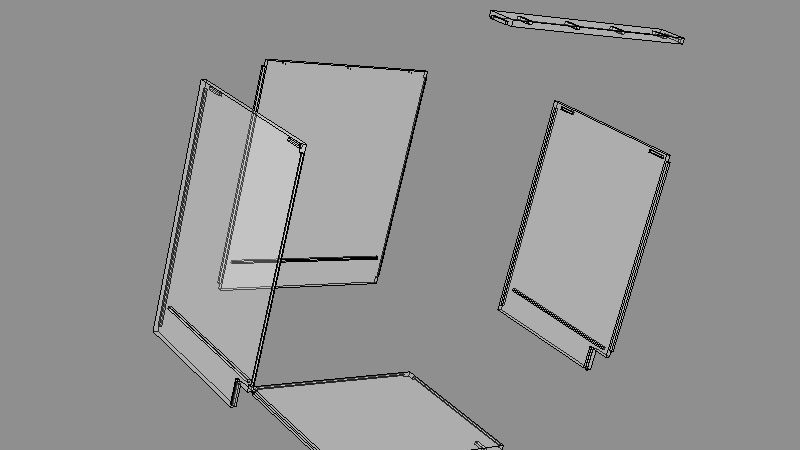

Click here for higher quality, full size image

From contributor O:

I use a 3/4" top nailer dadoed into the sides of the cabinet back for base cabinets. The back is 1/4" material that is dadoed into the back 1/2" into the left and right side. This gives me plenty of overlap in the material to put staples in to hold the back in place. For uppers I do basically the same thing except I have a 3/4" thick top and bottom nailer dadoed into the sides outside the 1/4" back of the cabinet. The top nailer is set up as a French cleat, so it is much easier to install the uppers. Mount the cleat on the wall, hang the cabinet, put in a couple of screws.

Click here for higher quality, full size image

From contributor W:

1/2" back inset 1/2". Full dado on sides, top and deck.

Click here for higher quality, full size image