Cabinet Door Clamping Options

From shop-built jigs to specialty clamps to clamping tables, there's a range of solutions for clamping doors when gluing up. March 25, 2007

Question

We outsource our doors, but we are set up to make them for little jobs or when we order one wrong. We clamp the door together with pipe clamps and then have to check for square and shoot. I don't want to give the money or the shop space for an actual door clamping system. Is there a better way, maybe some jig that can be built that will clamp the door and square it too, while not taking my wallet or my space?

Forum Responses

(Cabinetmaking Forum)

From contributor F:

I have the Taylor door clamp and it works great. It clamps and squares the door in one second. I think they are around 2500 for a new one, which is not too bad. The movable cylinder ones are way too slow compared to this one when changing from one door size to another.

From contributor K:

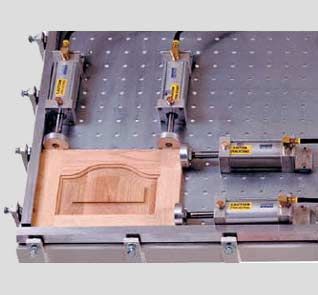

For a few doors, this simple jig works great. Screw it to a bench, glue up the door and lay it face down in the jig. Use two quick clamps to pull the joints snug, then use a block that spans both stiles and a pipe clamp to pull the door square into the jig, pin the corners, remove the door from the jig and clamp with two clamps. Works great.

Click here for higher quality, full size image

From contributor T:

I own a JLT door clamp. I think it is the same one that contributor F alludes to. It clamps and squares the door just fine but does not necessarily keep the door in one flat plane over the whole length of the clamp. The way the metal frame is produced, there is nothing to assure that the right side is in plane with the left as you get wider. We press the door on this frame and then lay it onto a Blanchard ground steel table we harvested from a printing press.

If I had the $2500 to invest again I would probably spend a day + $1000 worth of air pistons and do something along the lines of what contributor K suggests. My fantasy clamp would have a UHMW table surface for easier glue cleanup and there would also be air clamps that exert pressure down while exerting pressure sideways. My current clamp lives at about a 30º incline. I would probably make this a flat surface so I could use the space for other purposes as well.

From contributor A:

Ditch your pipe clamps for four Bessey or Jorgensen cabinet clamps. Bessey sells a set of four "stands" that hold the four clamps perpendicular. Pipe clamps tend to roll the pattern and you can end up with cupped doors. This is the $200 answer to your question.

From contributor K:

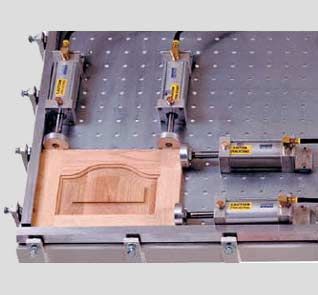

I agree that bar clamps are better. You can build a clamping table that has slotted rails to hold your clamps in position (had one of these in high school shop class), making life much easier. You would still need something to square the doors first. The ideal (or Unique) solution is the picture below. For just a few doors a month, I use the jig shown above. It is all about how many doors you are doing.

Click here for higher quality, full size image

From contributor A:

Either I didn't describe the setup correctly or you are not aware of these clamps. They have been selling them for 6 years(?). Bessey K-Body door clamp kit (kbk2450). Jorgenson calls them Cabinet Master clamps. They are not bar clamps. The Bessey kit is (2) 24" and (2) 40" with (4) grooved blocks. The blocks keep everything square. At the end of the day if your panels are square, the door should be square unless you rack it.

Your clamping jig is beautiful. However, it would take a lot of doors for that amount of effort to pay off.

From contributor K:

I have seen the clamps you are talking about but I never thought they would be as good for squaring a door as clamping the door into a fixed 90 degree corner. I don't really know because I haven't used them.

My door jig is the shop made one at the top of this thread, so I can't get too snooty. The other picture below is of the Unique door clamp which would be the way to go if I were doing a lot of doors. I don't own one. I have a very backward shop.