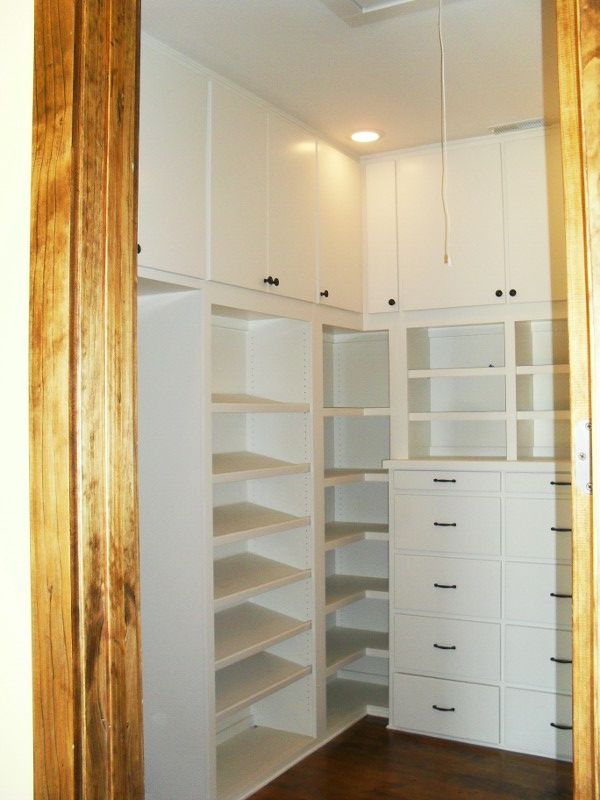

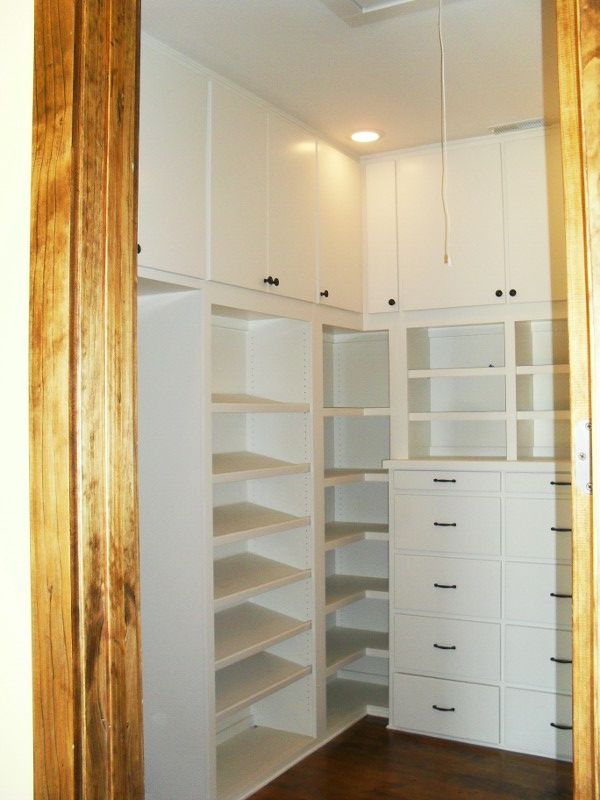

Cabinet Pocket Doors and Adjustable Shelves

A construction problem: how to build a cabinet with adjustable shelves, inset into a wall, with doors that open out and slide back into recesses next to the cabinet. August 30, 2010

Question

This cabinet is about 42 wide by about 46 tall. It is totally recessed into the wall 23.25 inches. What do you do when you have pocket doors with adjustable shelves? I have an interior skeleton with shelf holes drilled. Is there a better way? I know if the hardware fails I will never be able to replace it without tearing the cabinet apart. The hardware is the KV that uses the wood stretcher, with Grass half-inch overlay hinges.

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

Forum Responses

(Cabinetmaking Forum)

From contributor K:

You could run a stop dado in the top and bottom of the vertical panels and then drill in some shelf pins that the dados slide over, and then the panels will slide in and out.

From contributor G:

What he said, except instead of shelf pins, use Swedish shelf standards and stop dado the dividers accordingly. It works nicely, and assuming an accurate cut/fit, is completely unnoticeable and a much stronger construction, I feel, because of a more even distribution of stress on the divider itself - should it receive any laterally. Or perhaps the solution could be as simple as - just don't use glue, and screw the divider from the top/bottom?

From the original questioner:

I don't really know what you two are talking about - I can't visualize it. If you are talking about the skeleton with the shelf holes in it, they are dadoed in. But they also have a face frame in front of them. I have little blocks in the dados to keep them from showing.

From contributor G:

I did not notice that, however I would ensure the face frame is made to fit flush to the inside bottom of the case in order to make those dividers removable - if I felt the urge to. That is something I do with most of my face frame cabinets anyway. Speaking about that particular cabinet, and not the hypothetical "next"? I dunno, hope it doesn't fail?

From the original questioner:

If the face frame was flush, the dadoes would sit below the face frame and the dividers would not be removable.

From contributor G:

We are saying to dado the edge of the dividers to accept an indicator of some sort attached to the case itself. You could leave one side's face frame high in order to hide the dado in the divider. Install and remove the dividers from the other side.

From contributor R:

Why couldn't you design it as "two" separate cabinets? Build the outside case with the pocket door hardware mounted. Next, make a separate case, with the shelves, to slide inside that first case, like a component. The doors would conceal the joints when closed, or at least line up with the top and bottom lines left by the inserted second cabinet.

If you need to get to the pocket door hardware, you simply unscrew the inside cabinet, slide it out, replace the hardware and reinsert the interior cabinet. Of course, you would have to remove the outlet cover plates and unhook the electrical wiring, but how often are you going to be replacing the pocket door hardware anyway?

I use this method when someone wants to add a stack of drawers into a base cabinet that has doors. I build a component with the drawers inserted, then take it to the site and install it inside the opening. Drawer fronts then cover over everything when closed.

From contributor E:

I probably would have run stringers at the top and bottom behind the inner stiles and a vertical dado in the back and attached a removable panel (with the shelf holes) to stringers, just behind the inner stiles out of sight, with two screws.

From contributor Y:

When we build a retractable door cabinet with adjustable shelves, we drill the top and bottom with 2ea 5mm shelf peg holes positioned under the L & R panel being used to hide the retractable door. These holes would be in about 2" from the front and back, more if you choose. These panels would be drilled on the inside for your standard shelf drillings. On the outside of these removable panels (the side where the retractable door is) we drill in a plastic clip designed to keep shelves snapped on to their shelf pins. These clips are readily available, and allow you to remove the shelves, pull the L & R panels off the clips and access the retractable hardware, yet they are totally hidden under and behind the panels.

From contributor M:

I think I might be missing something, but have you looked at the KV 8091? It's made just for this application.

From contributor G:

Oops. My last response was treating the cabinet as if it were a pass-through... My apologies for being too careless in viewing the pictures and having flashbacks of doctors' offices/hospitals!

Assuming that the hardware does not mount on the dividers... Keep face frame flush to inside of case, and use locators (mounted on the inside top, bottom, and possibly even the back of the case) which nest into the edge of the vertical dividers (stop dado, or some such), as previously mentioned. You could then slide them in and out without issue. The entry cut(s) would be on the bottom/top/rear edge face of the vertical dividers, and would be completely unseen, yet allow them to be removed at will to access the hardware.

This could even be achieved with 3/4" tall wooden location cleats milled to the dado width in the edges of the dividers minus 0.02 as well. No real need to purchase additional hardware or drastically change the construction method other than that.

From contributor L:

We use the "box-inside-a-box" method. It uses more material, but for us it is the fastest to make and install.