Question

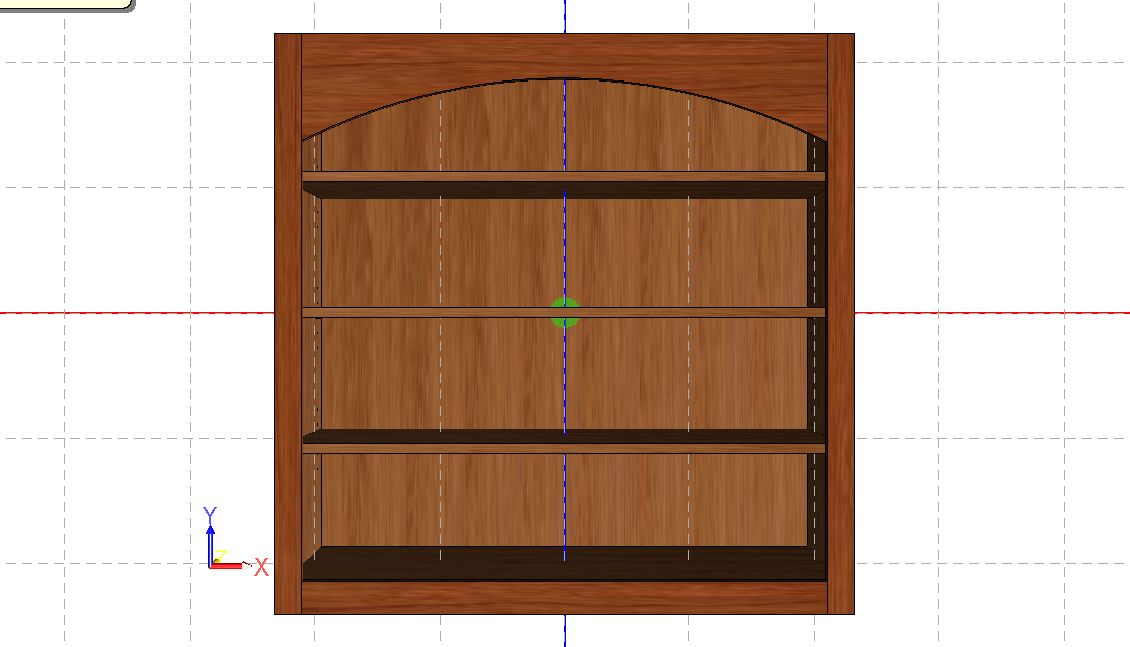

My main market is building kitchen cabinets and with the market slowdown I am getting more and more calls for built-in cabinets such as entertainment centers. I have one bid I need to put in and am kind of scratching my head a bit. This is for a cabinet that is 43" x 43" x 24" deep. This cabinet goes in a niche and will be encased with door moulding, no crown, adjustable shelves and no doors, stained using white birch. Its pretty basic but I am not sure how to price this. I am in central CA.

I have done several of these in the past and basically bid by material cost and what I wanted to make on the job. I definitely don't want to undercut but am worried about overpricing and losing every job in this market. Can someone help me out here? And I do know about overhead and figuring out what my costs are. I just would like to know what someone else normally charges for this.

Forum Responses

(Cabinetmaking Forum)

From contributor S:

I wouldn't be able to touch it for under $1,100. I know it's a simple design, but by the time you measure, meet the homeowners, draw plans/design, price materials, go over stain colors, and negotiate details "standards shelf pins, etc." I would say your vested time is already at eight man hours. Unfortunately, that's just to maybe get the job. Many people have unreasonable expectations, and usually people intend to spend right around what materials will cost. I battle myself constantly and would mentally talk myself down to about $900 and maintain my trade as an expensive full time hobby.

One other thing I failed to mention was the door casing surrounding this would have to be modified a bit to fit around the fire place and I would have to cut out the existing baseboard where the casing meets the bb. Not a whole lot of work but that is what I was looking for. I was figuring no more than $250 for materials and was looking for about $1,000.00. It may be a hard sale because the homeowner can see it is not that elaborate.

When building entertainment centers make sure you take into account wire runs and ventilation for the electronics. When these elements are incorporated into the design, the project will be better suited for its intended purpose.

Since you already know what your costs are, then you know what you need to charge and still make a profit. Do not sacrifice profit just to build something. If you do, you will soon find yourself out of business. Ask yourself this question - is it better to bid ten jobs at or below "cost" and get all ten jobs, or bid ten jobs with "profit" built into the price and get one or more jobs?

Even though my market is different than yours (northern New Jersey), here is what I would estimate:

Design: $375

Material: $375

Fabrication: $1,125

Delivery & Install: $500

Total Estimate: $2,375

The estimate includes a detailed description and the total project cost of $2,375 not an itemized list of costs. To move forward to the design and proposal stage the client signs the estimate and pays the non refundable design fee of $375. They then receive a drawing and proposal. To move forward to the engineering and fabrication stage the client signs the proposal and pays the progress payment. Upon completion of fabrication the client pays a progress payment and a delivery and installation date are scheduled.