Choosing Wood for a Shop-Made Hand Plane

In the olden days woodworkers made their own planes. You can still do it. Here are some thoughts on the appropriate wood.June 28, 2013

Question

I donít like the planes I have and I decided to make a few of my own. I have white oak, red oak, ash, walnut, cherry, and hickory. Which of these do you think would be best for making an 18-24 inch hand plane? Iíve already made a 4 by 4 by 18 inch from black and red oak (test case). Itís fun, easy, and not expensive so I will make some more.

Forum Responses

(WOODnetWORK Forum)

From contributor V:

I would guess that white oak would be the best of those. Walnut is too soft and I have no experience with hickory, although I know it is tough and shock resistant.

You could check and see what woods the English/European or American plane makers were using for the most part back when planes were the only tool used. It seems to me that hornbeam springs to mind.

From contributor W:

Walnut is not uniformly a soft wood - Carolina walnut is actually pretty hard. That said, I think hickory is harder. White oak is very good for many projects, but planes have been made out of many different kinds of hardwoods.

From contributor V:

Come to think of it, a lot of the old planes in my collection used beech.

From contributor Z:

Any straight grained hardwood should work fine. I agree with Contributor V on the white oak. I wouldn't use hickory because the grain might cause a problem.

From contributor B:

Historically, the most common wood used for making hand planes was beech and birch but those aren't on your list. Prior to the 1800's, all working craftsmen made their own planes and they made them out anything at hand. Don't feel bad about doing the same if you want to.

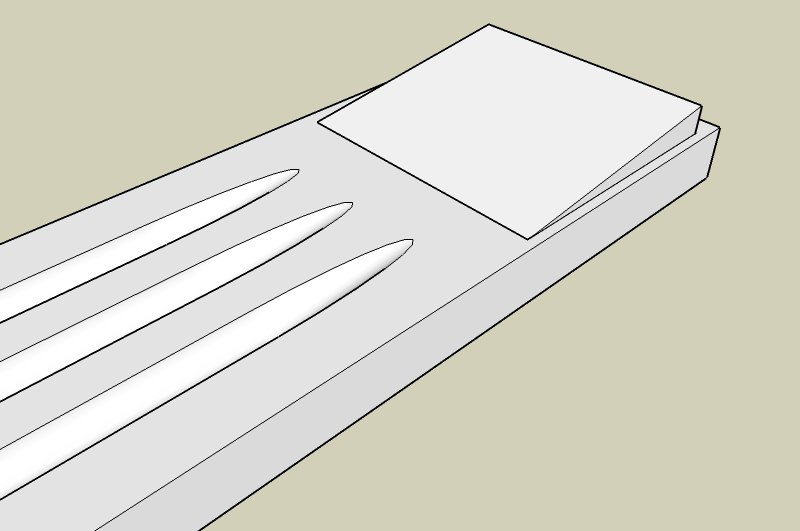

I think I would make the body of cherry because it's smooth to the touch and moderately hard. It won't splinter with wear or age like oak or hickory. Try laminating a hard, dark tropical sole to the bottom, like wenge or Brazilian cherry or just about anything that's really hard, smooth, and tight grained. Both the body and sole should have the grain set vertical or perpendicular to the face.

There are generally two types of guys making wooden planes today. The first guy is a real artist who cares more about the beauty of his homemade tools then any work he might ever do with them. His tools are fun to look at and don't have any scratches on them. The second guy is the one who cares more about the work and how to get it done. He's the guy who would reach into the dumpster, pull out a chunk of wood and have it made before I finish writing this blog. I am definitely the second type but I can still appreciate a well-made hand tool.

From contributor L:

As suggested of the woods you listed I would go with white oak. The Japanese make wonderful planes from it. The most important criteria is stability with humidity change unless you want to be flattening the sole every time the humidity changes for a while. The second most important criteria is hardness - at least of the sole. I'd rule out the cherry for both these reasons. I've used white oak, hard maple, padauk, and my favorite: cocobolo. Another consideration is a little heft so the cocobolo is good for that and provides some oil self-lubrication. Of all my planes itís the only one that I've not had to re-sole or add an insert to after wear and itís the one I use the most.

From contributor A:

I've made wooden planes on and off over the years, both for my own shop and as gifts. They're fun and not terribly difficult to make. I have a Japanese plane with a white oak body and it's perfectly ok. My own preference is to use a walnut body with ipe on the sole and sides. The reason for the walnut is stability. Walnut is prized for gunstocks because of its stability. Since walnut isn't hard enough to use on very hard Brazilian woods, simply glue on ipe. This adds a step to the process, but otherwise, no big deal. One last note, use a thick plane iron, like the Japanese do. Otherwise handmade wooden planes tend to have too much chatter.