Cleaning Spray Tips

Advice on cleaning the spray tips of air-assisted airless sprayguns. April 2, 2013

Question

When I clean my AAA fluid tips with the little metal needles, I think sometimes small pieces of the needles break off inside the fluid tip. Anyone have a way of getting them out? Where can I see a diagram of these fluid tips so I can see how the interior is machined?

Forum Responses

(Finishing Forum)

From contributor D:

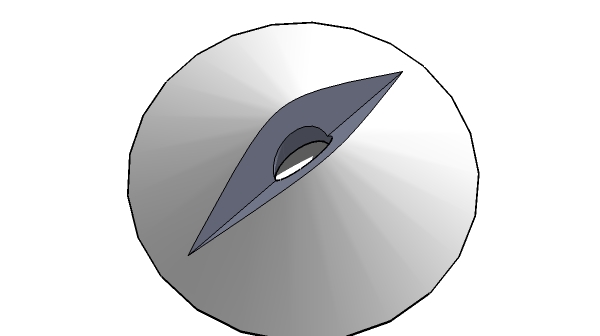

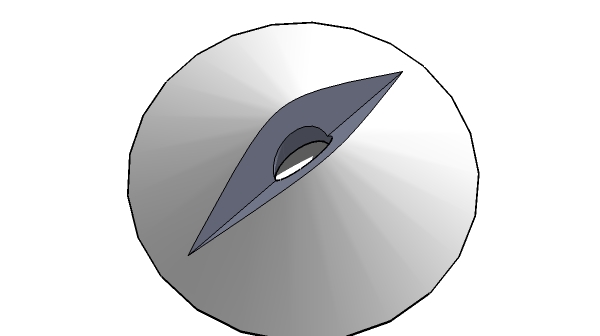

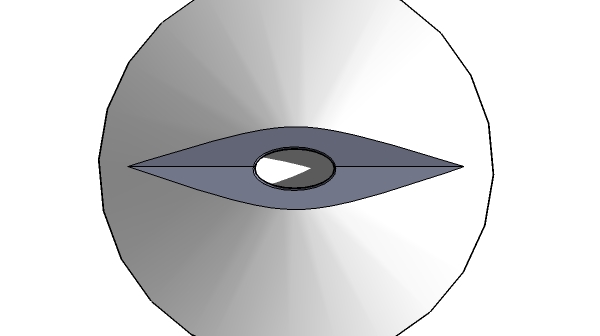

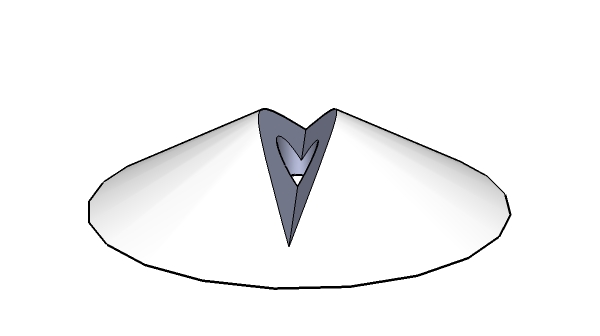

The hole is actually an oval and the cleaning needles can get caught in the small ends of the oval. I would use those cleaning needles as a last resort. I usually blow the tip with air to get the liquid residue out and then soak the tip and cap in gun wash. Not lacquer thinner, because it does not clean as well. You can also use a toothpick to kind of swab along the groove because it is much softer than the needle. That said, the tips are carbide, but I have reamed one out and it was junk after. Look through a jeweler's loupe.

Click here for higher quality, full size image

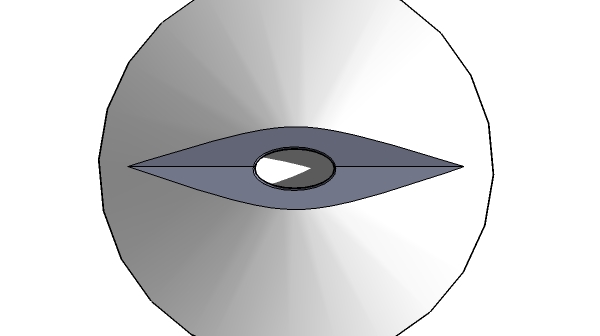

Click here for higher quality, full size image

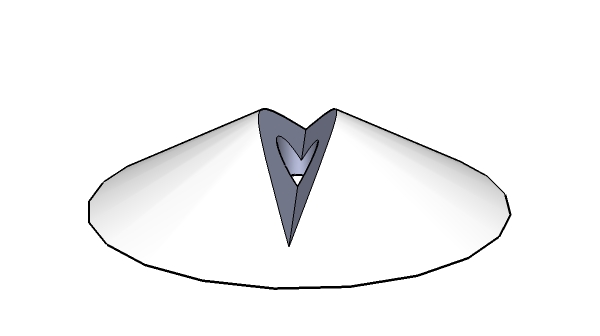

Click here for higher quality, full size image

From the original questioner:

Thanks. As for the diagrams, what I'm trying to find out is how the inside is made. If you look from the back side, the opening looks tubular. Is it a tube shape that ends in the oval opening, with no other hollow area inside the fluid cap?

From contributor R:

We use a heated ultrasonic cleaner for ours.

From contributor D:

That's right - the tubular shape is usually larger diameter than the oval orifice, but it is smooth. The oval necks the orifice down which creates the atomization. We are talking thou of an inch here, though. If you roughen that edge of the oval you will ruin the smooth spray pattern, then toss the tip in the garbage. Contributor R is right in that the best way to clean tips is with an ultrasonic cleaner. I don't own one but I will need to get one too.

From contributor W:

How does the ultrasonic cleaner work? Do you put solvent in it with the tip or is it dry? What kind do you have?

From contributor B:

I've had good results by just keeping a set of tips soaking in a can of thin liquid paint stripper. Before using it I'll give it a few blasts of air to clean it off. This seems to work quite well for the water based coatings too.

From contributor D:

Ultrasonic cleaner works by sending ultrasonic waves through a liquid which literally makes the deposits on metal explode off the surface. The waves of energy pass through the metal. It's a container in which you put your gun parts and it cleans them. Look them up on the internet and you will find there are many manufacturers. A good one may cost you 1K and up.

From contributor R:

We have the SRA TruPower UC-100D. We are pretty happy with it. We have a smaller one also but it is very noisy and not very well built.

From contributor H:

Here is the one thing that I try like heck to get my painters to do. Once they flush, put tip and aircap back on, crank up the pressure, and blow the tip. Since doing that I have no clogging issue.

From contributor O:

Faced with about 10 plugged Kremlin nozzles and no ultrasonic, I bought a can of SmartStrip paint remover from

Sherwin Williams, soaked the nozzles overnight, and brushed them off this morning. The nozzles were still plugged but the stripper softened everything up enough that a good blast with shop air cleaned them out.