Converting Bitmap Images to CNC-Machinable Files

Advice and show-and-tell examples of machining curves when starting with a simple drawing to import. September 15, 2011

Question

I have a drawing that I need to make larger in order to cut on my CNC. I have Biesse Works software and AutoCAD. How can I cut this piece from 1/4" material? 4' X 6'.

Click here for higher quality, full size image

Forum Responses

(CNC Forum)

From contributor S:

Is this for a job you accepted?

From contributor D:

You just need to insert that picture into AutoCad (Insert - raster image), and trace it, then scale your traced lines up to the size you want. Rhino has better line tracing tools, and you could download a free trial that will allow you to make 25 saves; you could export it as a .dxf, .dwg. or any other type you need for cutting.

From contributor J:

The image doesn't appear clean enough as it is. You could scan it, import into AutoCAD, vector it, put it in your CAM program and cut it.

From contributor M:

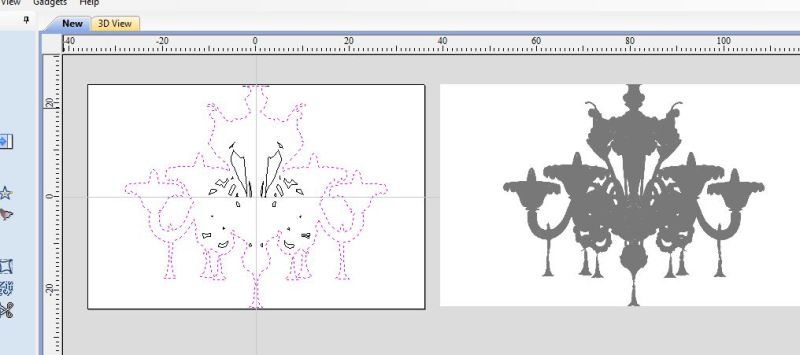

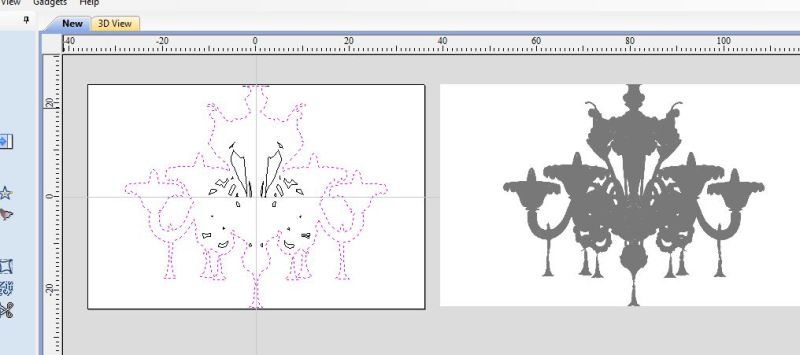

Aspire or Vcarve pro (along with any software with a raster feature). Once you obtain machineable vectors, you are on your way.

Click here for higher quality, full size image

Click here for higher quality, full size image

From contributor O:

What is "raster"?

I have been thinking of VCarve for awhile, just not sure how much use I will get from it.

From contributor M:

Raster is to take a shape (bitmap, jpeg, etc.) and convert it to pixels or vectors that can be read by a printer or, in our case, CNC cam software. Vectric provides all of their software and training videos free online for complete demo. There are some included files so you can test the post processors on your CNC and learn the software before you purchase. I am building a fairly complex set of trophy stands for a national trophy (college baseball) and the architects sent me the full scale dxfs. I will show it after install. This is another piece I have done recently. The rope border is 72" in diameter.

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

From contributor Z:

That trophy is incredible! What was the total machining time on that bad boy?

From contributor M:

I got 12 hours in the initial run.

From contributor G:

I'm not getting the best from my machine, looking at that work.

The machine is a Camaster and as far as I am concerned has taken all comers and passed all test. However, most CNC machines can do this in one form or another.