By Ed Ferri

Ed Ferri is the founder of Quality VAKuum Products, Inc. and has more than fifteen years experience working with vacuum applications. QVP specializes in vacuum pressing and clamping equipment for the woodworking and plastics industries. For more information visit the QVP website at www.qualityvak.com or call 800-547-5484.

Outside bag forming is a proven technique to save time and money in the production forming of anything from simple curves to complex spiral staircases. There are several advantages:

- The form does not have to be as strong.

- The form can be used with several bags without waiting for the glue to dry.

- Less flat spots.

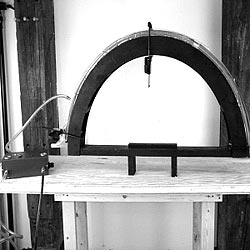

Here are the steps to make a curved arch or jamb.

1. Glue the laminates.

2. Stack the laminates and tape together using fiberglass reinforced tape. Apply the tape so that the sticky side is away from the work. You want the laminates to slide when being bent over the form. The tape also holds the mesh in place.

3. Wrap the laminates in plastic window screen material. The mesh is required to allow air to get out of the bag. Without the mesh, the bag would seal around the vacuum connector and prevent the bag from being fully evacuated. The fine mesh also helps protect the bag from sharp corners. Tape the sharp edges of the ends or cover with cardboard.

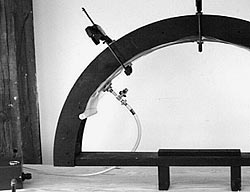

4. Slide the assembly into the bag, making sure the vacuum connector hits against the mesh.

5. Bend the bag over the form and apply clamps to hold the shape. The bag does not do any bending - you do. The bag does all the squeezing.

6. Evacuate the bag. It is now squeezing with 1800 lbs/sq.ft. of even and uniform pressure.

7. If you have multiple bags and a manifold, remove the bag from the form and hold the shape with a bar clamp across the bottom if the laminates are so stiff that they spring out.

8. Repeat the process for multiple bags.

Tips

A. Use a piece of fiberglass reinforced tape to hold two pieces together for a spliced joint.

B. For a small or tight radius, push the bag into a female form. The top of the bag is smooth and without wrinkles. On smaller arches, the wrinkles can make a dimensional difference.

C. Use VAK Bond 2000 urea glue for a rigid bond and no or minimal spring back.

Ed Ferri is the founder of Quality VAKuum Products, Inc. and has more than fifteen years experience working with vacuum applications. QVP specializes in vacuum pressing and clamping equipment for the woodworking and plastics industries. For more information visit the QVP website at www.qualityvak.com or call 800-547-5484.