Designing a Corner Sink Cabinet

Cabinetmakers put their heads together on a cabinet-building problem. October 26, 2005

Question

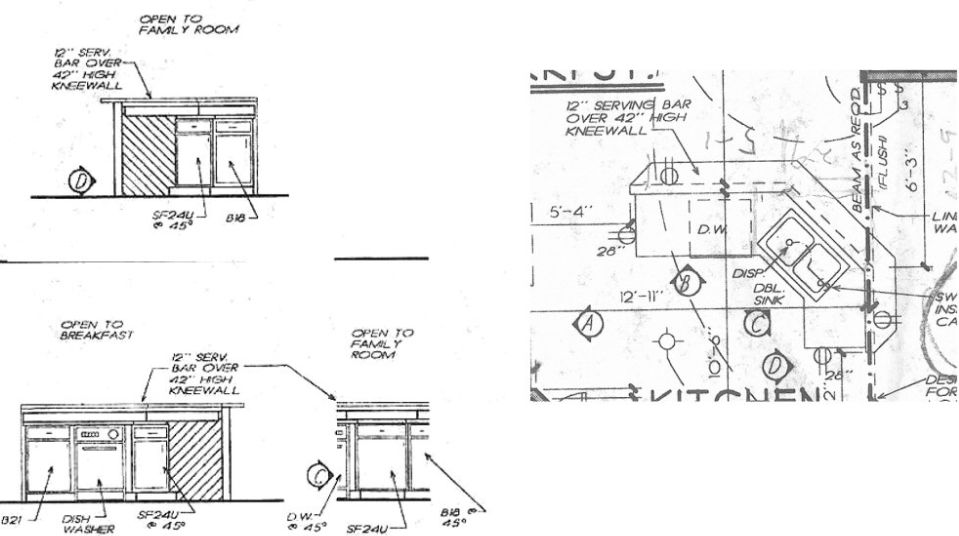

Here is a print of a kitchen bar that has a full size sink. The trouble is it's labeled 24SF and it's on a cut corner... I have an idea, but thought I'd ask the experts.

Click here for full size image

Forum Responses

(Cabinetmaking Forum)

From contributor L:

It looks like the builder intends for you to build a trapezoid shaped cabinet so the sink will be confined within the cabinet. The cabinet to the left of the DW is a simple standard cabinet. The cabinet to the right of the sink unit is another standard cabinet. The sink cabinet would have to have an extra piece of face frame on a 45º angle to make it look like the DW has its own cabinet to sit within. If you make the sink cabinet a standard rectangular unit, I fear the sides will have to be cut to accommodate the sink. This would be fine unless you can see it within the DW area. Otherwise, you need to build a special cabinet or use a smaller sink. Sometimes you have to explain to the customer/builder that you can't stick a 6" block in a 5" space.

From the original questioner:

That is my opinion, too. (An additional 45 degree wing on each side. Now how to figure out how big to make that wing. I think 2 1/2 inches will do it.) I would love to talk the builder into expanding it a few inches, but I don't think there is space in the room. I will have to look at the print again. I had to draw the thing out full size to figure out the dimensions. Even now I am not 100% sure if my figures are correct. I guess I'll find out when I build it.

From contributor G:

Rather than make this thing more complicated than it should be, figure out what you would do if you had to use a factory cabinet. My bet would be that they would use a 24" sink base and cut the sides for the sink to fit in the corner. If you build that trapezoid shaped cabinet and the framer has framed the kneewall at a strange angle, you will have a hard time making it fit. We do this type of setup regularly. All of my builders know to make the sink kneewall 60 in long (which will manage a 36" cabinet just right).

From the original questioner:

In this case, I told the builder I would build the knee wall, just to avoid that type of problem. Plus, being that I claim to be a custom cabinet builder, I better make one that fits correctly.

From contributor L:

As I looked at the drawing closer, I notice that a trapezoid cabinet wouldn't fit because of the knee wall. It would need to be a stretched out hexagon. Build it rectangular and cut out the sides.

From contributor K:

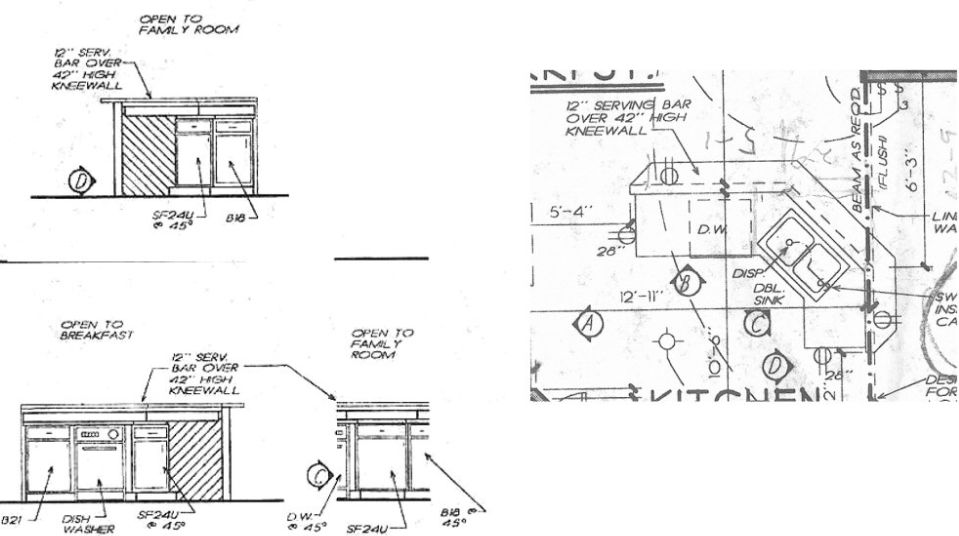

I would do something like this. I hate to see the sides of a cabinet cut out to make a sink fit.

Click here for full size image

From the original questioner:

Nice drawing. What did you use ?

Also, is it 24 across the front? It looks wider than that. The only solution I can see is to add 45 degree wings to the sides. Not fun, but if you're space challenged, you do what you have to.

From contributor K:

Sorry, you are correct - I misread the print. It made it easier to get the sink in, though. LOL.

Okay, here it is with a 24" front. It looks like you could just squeeze in a 33" sink but I think I would draw it out full size before I should trust it. Also, it would depend on the sink bowls.

These drawings were done using eCabinet Systems software.

Click here for full size image

From contributor B:

Build a pony wall for the back side, then just use a false gable for the dishwasher with 45 degree fillers on each side of the sink cab. That way, you can use all standard cabinets and be done with it. Unless you have quoted it out as a one piece item, do the same, but put it together in the shop.

From contributor D:

Attach 45's, as said earlier. Build cabinet with sides dropped down 10" or so to clear sink - no cutting (butchering) on job.

From contributor V:

I think contributor L hit it on the head. Put some wings on the face frame sides and cut your deck to match - this will give enough room for the sink to fit without cutting into the sides of the carcass. If you have CAD, draw it out first and look at it - it will come to you, I'm sure.

From contributor M:

I did one of these layouts a while back (there were blueprints on it, also) and the customer ended up paying me to relocate the dishwasher further from the sink. They were freaked out by the fact that to load the dishwasher, the racks actually rolled out behind them when they were standing at the sink. I actually consider this an advantage in loading, but they didn't. You might want to call this to the owner's attention.

From contributor R:

Is there a set of French doors to bring it in one piece? If not, I would just build a modular sink base the same length as the short point on the knee wall. I would glue and screw knee wall together, then screw the 12'' tops core to knee wall, then laminate it.

From contributor P:

I would build the cabinet to properly fit the sink in width. Then I'd knock off the front corners at a 45 degree angle far enough back to clear the DW and the other side cabinet. Depending on the sink, the 45 degree corner may be as wide as 8" and go back as far as the corner of the sink bowl. A ply side on the 45 and you have an enclosed base without dealing with the hex issues.

From contributor W:

Too bad - you could put the sink centered where the dishwasher is and put the dishwasher in the angle or, better yet, in the far right of the island.

AI enhanced answer (added Jan 17, 2025):A corner sink cabinet maximizes space in a kitchen or bathroom by utilizing the often underused corner area. Here's a simple design:

Dimensions: Typically, the cabinet would fit into a 36-inch by 36-inch corner space, but this can be adjusted based on room size.

Structure:

-

Base: Construct the base from 3/4 inch plywood, ensuring it's level for the sink installation. The base should extend slightly beyond the cabinet's footprint to accommodate plumbing.

-

Carcass: Use 3/4 inch plywood for the sides, back, and front frame. The sides are cut at a 45-degree angle to fit snugly into the corner. The back panel can be full or partial, depending on access needs for plumbing.

-

Doors: Install two doors, each hinged on the outer edges, allowing them to open outward. A lazy Susan or pull-out shelves can be incorporated for better access to the corner space.

-

Sink Cutout: The sink cutout should be centered, with enough space around for the sink's rim. Ensure the cutout is reinforced to support the sink's weight.

Features:

-

Shelving: Include adjustable shelves or drawers for storage.

-

Finish: Apply a water-resistant finish or paint to protect against moisture from the sink.

-

Hardware: Use soft-close hinges and handles that complement the kitchen or bathroom's aesthetic.

This design not only makes use of the corner space efficiently but also provides ample storage and a functional sink area, enhancing the room's utility and appearance.