Drawer Slides and Stock Thickness

Can drawer slides standardized for use with half-inch material work if you build your drawers from 3/4-inch stock?June 16, 2014

Question

Can these be used together? I realize I'd need to adjust my drawer box width, but can't find it in the literature whether or not they work with 3/4" material.

Forum Responses

(Cabinetmaking Forum)

From Contributor S:

Yes use the 563F Series. Deduct 7/16 from the opening.

From contributor D:

You can use the standard 1/2-5/8" ones if you trim the lip down to 5/8". It's not something I would normally do, but it works.

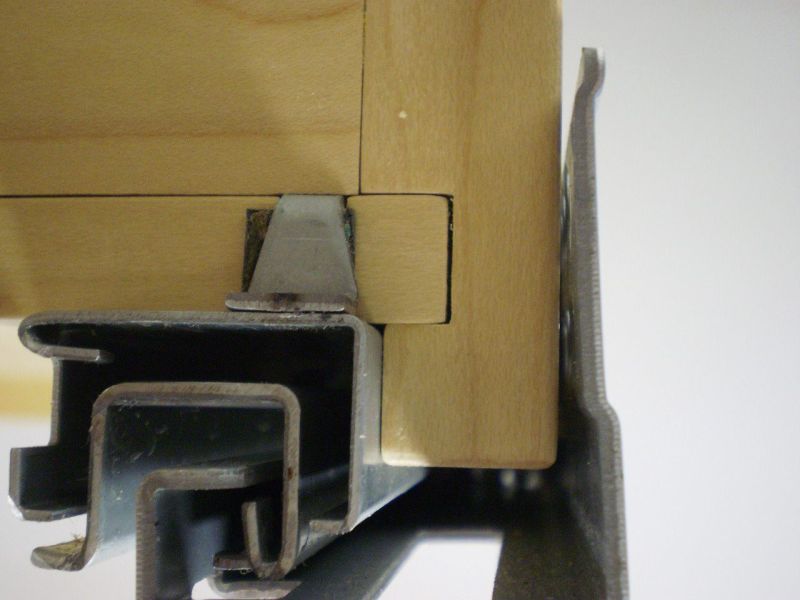

Click here for higher quality, full size image

From contributor V:

The slides that are made for 19mm (3/4") material are substantially more expensive than those made for 16mm (5/8" or less) material, so I often use Contributor D's method and it works just fine. You may have to see if you can conveniently do this with your construction method.

To contributor D: How do you build your drawers and why is the back (and presumably the front) of the sides and bottom edgebanded?

From contributor M:

If the face is also 3/4", and you build a 21" deep drawer - won't you also have to cut down the thickness of the face for the clips? I wouldn't think the

Blum slides work with material over 5/8". Correct me if I'm wrong.

From contributor B:

The 563F for 3/4 is only $0.81 more than the 563H for 5/8. I wouldn't mess around modifying the drawer for that.

From contributor V:

To contributor B: Where are you getting your slides and what is the cost of a 21" length for 5/8" material? Grass DynaPro is 25% more for the 19mm (3/4") version and I seem to recall that the difference was similar for the Tandem's when I was using them.

From contributor V:

To contributor M: With the DynaPro slide the front of the drawer does not need to be reduced in thickness like the sides.

From contributor M:

Sorry - I thought we were talking about

Blum (per OP post) slides here, my questions refer only to

Blum.

From contributor D:

To contributor V: I'm pretty fussy about banding edges that might get seen. That particular drawer is unique. There's no sub-front (because of the scooped face pull), the face is doweled to the sides and has a stop dado for the bottom. To get the clips butted to the face (not necessary with a 1/2" bottom, but it looks better and I needed the extra space behind the drawer). I shortened the slides with a metalworking notcher.

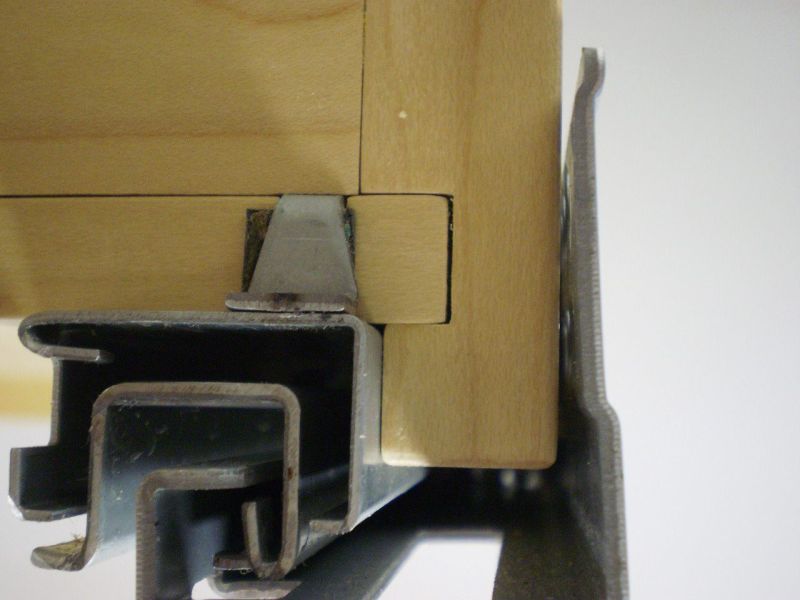

Click here for higher quality, full size image

From contributor V:

I just checked my sample

Blum Tandem with soft close in the 16mm (5/8") variety. It is being used with a 3/4" pre-finished plywood box and while I reduced the front, it was not necessary. The reduced front allows the drawer front to be pulled tight to the cabinet and if it wasn't reduced there would be about 1/16" space between the DF and the cabinet, which would be equal to or less than a bumper. I urge anyone who is thinking of doing this to run samples for themselves to confirm that this will work.

Note: There is no difference between the 16 and 19mm DynaPro slides except the width of the cabinet member and I believe the Tandem is the same way.

From Contributor Z:

I used the

Blum "H'S" with 3/4 pre-fin ply and it all fit perfect until I installed latches and then blinking boxes that extended 1/4" past the frame. I was going to notch the front but the

Blum rep said to go with the "F" series.

From contributor V:

It sounds like something is hanging up and not allowing the drawer box to seat on the slides properly, especially since everything worked before the clips were installed. I have had this happen with the slides that have the side-to-side adjustment. I would double check everything carefully before proceeding.