Drawer Slides for Inset Through Dovetail Drawers

Cabinetmakers consider how to rig drawer slides for inset cabinet drawers with through dovetail joints on the drawer fronts. September 27, 2008

Question

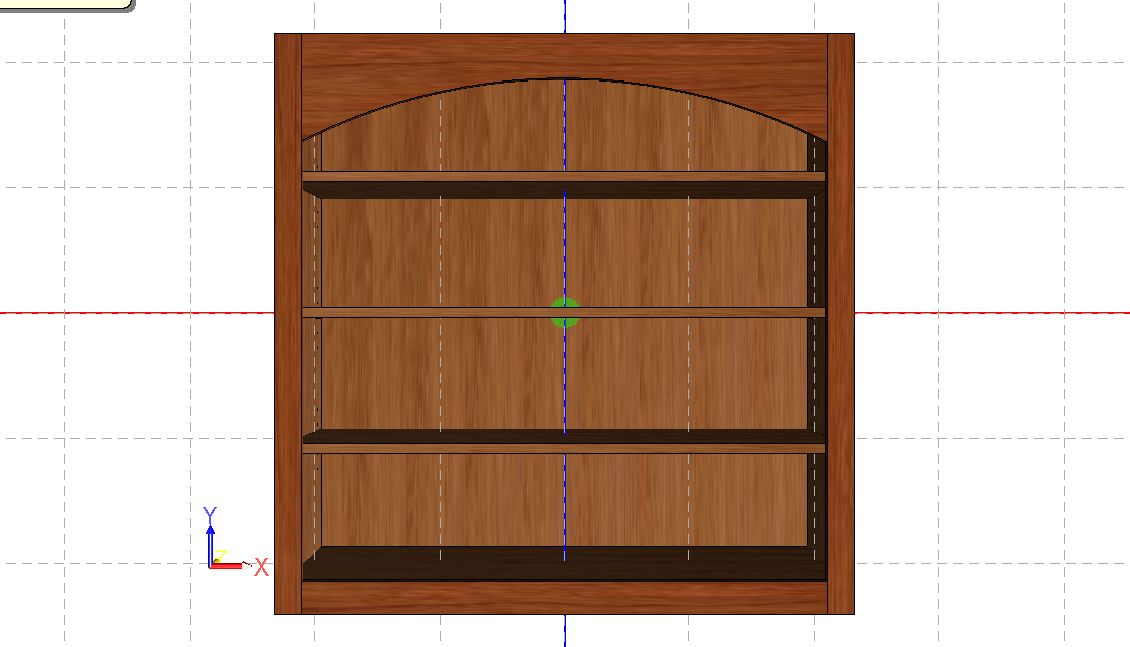

My customer wants through dovetails on an inset kitchen job. What type of undermount hardware can be used without a drawer front - like what is pictured below? I don't usually use undermount drawer slides so I want to make sure that I won't be able to see the drawer hardware.

Click here for full size image

Forum Responses

(Cabinetmaking Forum)

From contributor A:

Blum Tandems require 9/16" room beneath the drawer plus 1/2" room below the bottom. They also require 3/8" of room in width which is another problem. You could use Accuride slides mounted horizontally. However, this substantially lowers their weight loads.

From contributor B:

You can't get that look with Blum type undermount drawer slides. The Accuride type slides are not designed to work on the horizontal and will fail if they are used that way. The only option is a center mounted (furniture type) center slide which is not durable enough to use for kitchen cabinets.

From contributor C:

Why not make a drawer front with the through dovetail look, with a drawer suitable for undermounts?

From the original questioner:

I have been thinking the same thing. My only concern is whether or not those pieces will stay in place over time.

From contributor B:

It would be better just to tell them "no".

From contributor D:

Could you use a stopped dado in the side of the drawer box for a side mount bb slide, and maybe use a 20" slide in a 22" drawer box and set it back in the carcass so it would not show? Obviously this is a high end job. I can't think of any way to use undermounts without unwanted gaps or hardware showing. Could you let your front drop below the sides a half inch to hide hardware?

From the original questioner:

I have been thinking of telling them "no", but I like to be innovative and at least try to meet the needs of my customer to a point. To contributor D: I think you may be on the right track. I just need to think more about what you posted.

From contributor C:

I would think with good glue this would not be a problem. But the key will be getting nice fitting pieces. With sloppy fits nothing will work.

From contributor D:

If I went with the attached drawer front, I would just make the sides a couple of inches long, glue them up, and then buzz them off a few thousandths strong and then flush sand. I believe this would be the easiest way if it satisfies your client. Charge for a full mockup if possible. Turning down work in this economy is a tough thing to do and might bite you later. I know that for the first time in 15 years I am starting to get concerned with my backlog and work coming in the door.

From contributor A:

Accuride does make ballbearing slides that are designed for under drawer horizontal applications. They do not have the same substantial rated weight loads. They are center mounted and have a rating of 35 lbs a piece. A pair should handle any typical drawer load in my opinion.

From contributor E:

KV or Hettich makes a heavy duty ball bearing slide that should work for you application as long as you can put the bottom up far enough to conceal them.

From contributor F:

Any piece of hardware would be a disservice to this project, if you are building what is in the photo. Why not make traditional wood runners? If done correctly they will function better over time.

From contributor G:

Wood is the only way to go. You can even make full extension wood guides.

From contributor H:

You can use Blum Tandem slides for this with inset adjustable locks. The drawer box will need stopped blind dados for the bottom panel set at 1-1/16 in. up from bottom. The drawer box needs an extra 5/8 in. length. The sides and back are cut down (up from the bottom) by 9/16 in. This will give you 1/2 in. under the bottom panel on the sides and back and 1-1/16 in. at the front. A 5/8 in. x 1/2 in. filler is used behind the front for the locks. The slides are set back from the face frame, in this case 5/8 in. Looking at the drawer side, the front is extending down by 9/16 in. and will be in front of the slides. The inset locks will allow you to fine tune where the drawer stops and move the right or left side up and down in the back of the slide. You can move the drawer up and down also. The side clearance is 3/16 in. and by overhanging the fixed part of the slide you can make it as small as you like. For a full kitchen of drawers this works very well.

From contributor I:

I've done this before using wood slide of sorts. I made a stopped dado in the side of the drawer and made a strip of wood to mount on the sides of the cabinet. Put a drawer stop on the back of the drawer so the drawer does not pull all the way out.

From contributor J:

The Blum tandem slides work great and you can make them work. From the back side of the drawer front the lower tenon will be partially cut off, however the front will still look good. Judging by the look of the cabinet you would be able to make this work.