Euro Hinge Bore Locations and Door Reveals

Detailed advice with drawings on laying out hinge locations to achieve the desired door gaps. May 4, 2011

Question

I'm tooling up for a large inset cabinet job. I would like to use all the same hinges that give me equal overlay to make this job less of a cluster. Blum is my choice. Iím looking at getting your opinions using the 9mm plate or going with a shorter bore hole distance of 3mm. The door thickness equals 13/16".

I'm looking at a 4mm in some instances with a 3mm reveal. I can get away with a 3mm bore distance for most everything without the use of 9mm plates, etc. These hinges get me that 107 clip top full crank, 100 full crank, 95 thick door. With 120 I would need 9mm plate, same with a 170 with an odd 3.5mm bore distance for both. Any tips or suggestions for this would be great. Is there a safer/more controlled method?

Forum Responses

(Cabinetmaking Forum)

From contributor B:

You stated this to be an inset job, and are asking about overlay? If youíre asking what hinge would be preferable, go with 170.

From the original questioner:

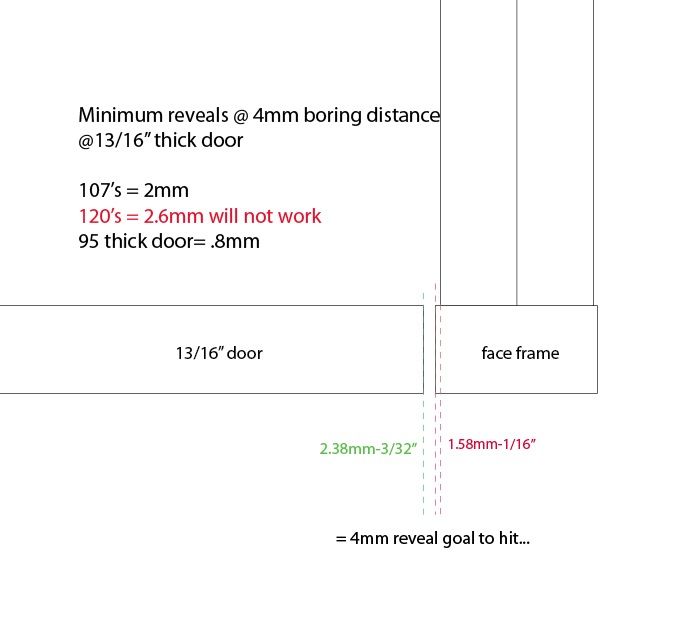

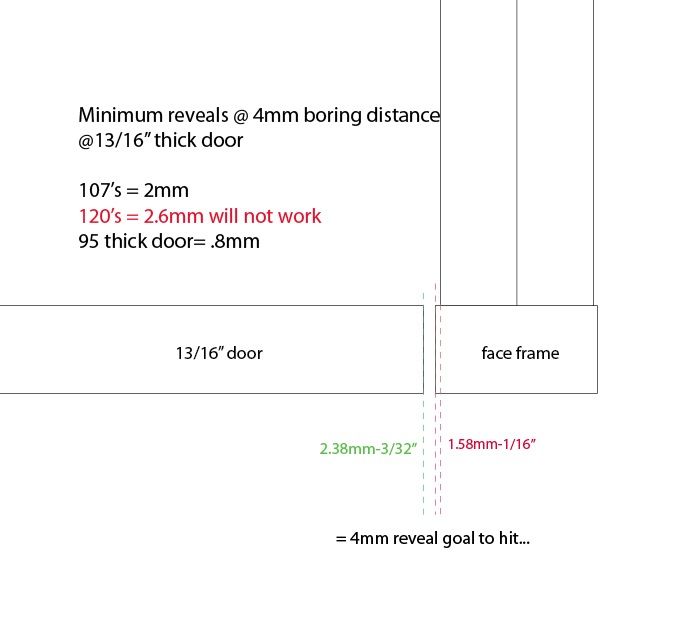

Lets replace the word overlay with reveal and in some instances bore distance. Why do these euro hinges have to be so unexplainable? I have posted a drawing of what hinges will and will not work. The hinge in red would be a tough sell.

Click here for higher quality, full size image

From contributor D:

There is a much simpler way to accomplish this using the same hinge, plate and bore distance for all of the doors. You can also reduce the gap from 4mm down to 2mm which would be much more aesthetically pleasing. The

Salice 110 degree, inset hinge will accomplish this using a 3mm mounting plate and a 4.5mm edge bore distance for all doors. You can use the 165 degree, inset hinge for corner cabinets with the same mounting plate and edge bore distance.

From contributor D:

Your edge bore distance should be set at 5mm. This hinge, plate and bore distance combination will hold true for all of your doors with this detail. It sounds like you may be in Minnesota somewhere since you mentioned HDL.

From contributor C:

The hinge I use is

Blum 71T5650 with a base plate 175H5030.21. You have to have 1/2" clearance on the inside of the face frame with this baseplate. The same hinge with a 6MM height means the carcasse has to be flush with the faceframe opening.

From contributor D:

You are correct. In this application the side is nearly flush (-1.5mm), hence the 6mm plate.