Euro Hinges with a 1/4" Overlay

A cabinetmaker wants to switch to Euro-style hinges, but isn't sure how to work with his doors' one-quarter-inch overlay. Here's how he solves the problem. May 22, 2007

Question

I would like to change my existing old style hinges to concealed European hinges on my kitchen cabinets. However, I only have 1/4" overlay available on the doors and I can't seem to find any 1/4" overlay European hinges. Is there such a thing as a 1/4" overlay concealed hinge?

Forum Responses

(Cabinetmaking Forum)

From contributor M:

Use a half overlay and then use a 3mm plate. This will give you a 1/4 overlay.

From contributor J:

Use Blum Compact 33 hinges with 1/4" overlay plates. Compact 33s have hinge plates available that run from 1/4" to 1 5/8" overlay.

From the original questioner:

Thanks for the responses. Yeah, that Blum 33 and the 1/4" overlay plate just might be the ticket. However, I was also thinking of just adding a 1/4"- 3/8" shim strip of wood to the opening on the box on the hinge side. The protrusion thingy on the 1/4" overlay plate looks like it might cause problems. Any pros or cons on either method would be appreciated.

From contributor B:

One thing you have to watch on the compact hinges is what edge profile you have on the door. Many profiles are so deep that you actually have to bore through in order to sink the hinge deep enough. Another thing is that the hinge boring must be really close to the edge of the door to make them work right. Just replaced 24 pairs of compact 33's today with long arm hinges because the doors were bored at 4mm instead of 2.5mm.

From contributor G:

Be aware that the pivot point of euro hinges is different than your old hinges. With 1/4" overlay, when open, the door will not be fully out of the opening. It may interfere with rollouts unless they are spaced in to clear the door.

From the original questioner:

Are the compact hinges different than other European hinges? True, the placement of the hole will be crucial as there is a sloping profile on the inside and outside of the stile. I do believe that bored in the center of the stile the hole would work (just barely), unless the compact hinges are a different depth?

Contributor G, thanks. No rollouts. Sounds like a good idea, though.

All these problems are why I'm curious as to your take on lessening the width of the opening via a strip of wood as I mentioned above, thereby making it easier to find a decent hinge that will work properly.

From contributor B:

By sloping profile on the outside of the stile, are you talking about a finger pull edge? If so, I don't think you'll find a euro cup hinge that will work correctly. Compacts and long arm hinges both require the same hole boring, but the placement of the hole is a little different. If you're talking about the center of the stile, I think you're out of luck. Don't know what you've got now, but I'd look at a Youngdale #5 hinge. All things being equal, I think it would be your best bet after hearing all the facts you've presented.

From the original questioner:

Let's just assume that I can get the hole drilled. It will be tight, but as far as the tape goes, it will work. I just need to figure out the best way to mount the bloody things. As far as the profile of the stile, it is a basic raised panel door. Nothing too fancy. Just a little ogee slope on both edges. 2" X 3/4" wood. Am I the only one in the world who ever wanted to change out his old style hinges to European? I sure can't find much info about it on the web.

From contributor B:

One more thing and I'll quit. Remember that the compact hinge must be drilled 2.5mm from the edge of the door. If there is a sloping profile, it is 2.5mm from where the edge would be if there was no slope. You just have to be sure the door will swing all the way open without hitting the edge of the door. If it were me, I'd mimic a door with a plywood scrap, run a similar edge profile, drill it, and see if all will work before you commit to a door.

From the original questioner:

Thanks. A guy at one of the top hardware stores here told me 3/16" from the edge for the Blum 33 (we don't do mms in Florida yet). I have one door I can play with so I'm going to get a hinge and have it drilled tomorrow. The shop that will drill is a little leery also (but eager and willing). We'll see. There's got to be a way.

From contributor B:

3/16" will give you trouble. No more than 1/8" from the edge. I had to replace 48 hinges yesterday with a long arm hinge because the edge of the door was binding on the mounting plate. Doors were drilled about 3/16". Never had a problem boring at no more than 1/8".

From contributor C:

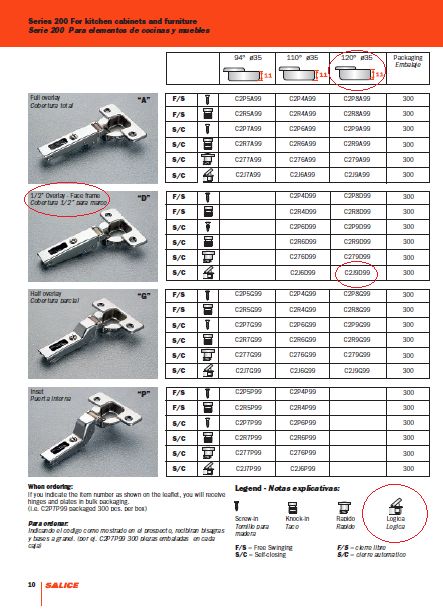

If you're still looking for a hinge, there's a Salice that sounds like it's made to order (if I understand the problem): SAL-C2P6G99-BAU3R49

1/4'' ol ff. The 6.35 mm (1/4'' in Floridian) distance from the edge of the door to the bore should help you miss the ogee profile.

From the original questioner:

If anyone's interested, I had a test door drilled. Seems to work. Got some hinges, seem to work. Blum, 71t5550/01 hinge 120D clip FO SC. 175L6660.22/baseplate clip FF 1/2 overlay. Don't know how or why.