Question

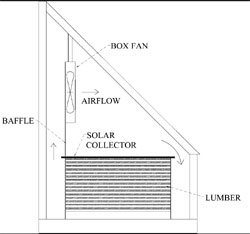

I thought I was ready to start building my solar kiln. I do have the exterior design complete. I was going to follow the design principals of the Appalachian State Solar kiln placing the fans in front of the charge and drawing the air through the collector. However, I see from almost all the kilns pictured here and all over the web, most have their fans mounted at the top of the kiln, pushing the air over the collector then through the charge, Virginia Tech style. It would be somewhat easier to place the fans at the top of the kiln. It appears to be a personal choice, since both designs appear to be successful. Comments on the pros and cons on the placement of the fans in front of the charge are appreciated. The drawing is of the VT style.

Forum Responses

(Sawing and Drying Forum)

From contributor W:

It would seem to me that that the Appalachian Solar kiln would be a bit easier to place fans into. Just build a wall, put the fans into it, and put in into position (on the floor). The Virginia Tech design is essentially the same thing, although, the fans are higher up. I am 6’3” tall, and don’t particularly want to have the fans/wall in the way of moving lumber around. I can foresee many a cracked noggin if I used that design.

The Appalachian State design uses the “fan wall” and the 12” rafters in the roof to pull the heated air through and force it through the pile. The Virginia Tech design uses the fan wall with a drop down baffle to pull the air through the pile. So, essentially, one uses the fans to push the heated air, and one uses them to pull the heated air.

I hope this helped in some small way. This is, of course, just my opinion, and I am sure that there are others out there with other (possibly more professional) opinions than my own.