Finger-Joint Miter Joinery

Thoughts on a finicky joinery detail. February 27, 2015

Question (WOODWEB Member) :

How is it possible to finger joint mitered cabinet doors, like the ones done in large shops?

Forum Responses

(Cabinetmaking Forum)

From contributor K:

We use a Bacci Miter Door Machine. It cuts the miters, drills holes for dowels and cuts the splines.

From the original questioner:

I was wondering how it could be done with a shaper? I tried and canít seem to get everything aligned once I pass it in the shaper to do the finger joints.

From Contributor K:

I do faux fingers on the tablesaw. I have a sled with a V carriage, into which I set the corner of the frame, (quick-glued with CA and accelerator) and use the fence to set spacing in successive kerfs. Glue splines into kerfs and voila, mitered (fake) finger joints.

From contributor G:

A million years ago I worked at a shop that did this with a heavy metal jig run on a bearing on a shaper. Of course I don't think this would pass OSHA today. Not sure what you are trying to do. You might consider using two dowels that run parallel to the stiles and perpendicular to the rails, using a simple boring machine.

From contributor L:

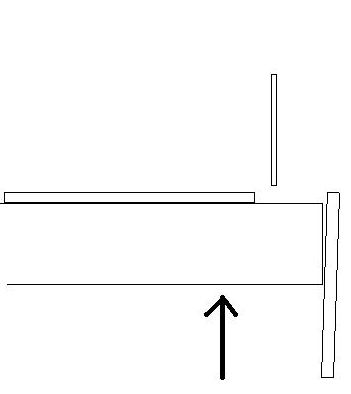

With single cutter face up/down cutting, material thickness consistency and cutter height are critical. If the cutter height is off by n, the faces will be offset by 2 x n. Splines are a lot more forgiving.

Click here for higher quality, full size image