Finish Defect Spots on Outsourced Doors

Contamination during handling is an occasional problem with doors shipped unfinished. September 16, 2008

Question

We have just received doors from a new company. When we finished the doors several of the doors had spots that the finish would not cure on. We used ML Campbell Magnamax and have never had this happen before. Does anyone have any ideas?

Forum Responses

(Finishing Forum)

From contributor P:

Did you sand the doors prior to finishing, or were they stained? Maybe the problem is in the stain not totally drying. If you let them sit does the finish eventually dry?

From contributor F:

Sounds like some type of surface contamination but I need more info. What type of wood – solid or veneer? Were the doors stained, and what type of stain if so? Does it seem completely random or is it in a particular part of the grain or darker stained areas?

From the original questioner:

The wood is solid maple - no stain, just clear coat. It seems completely random. There were no visible discolorations or contaminates. We did not sand prior to the first coat, but sanded after the first coat. The same thing happened on the second coat.

From contributor J:

That could be anything including grease from the French fries the delivery guy ate for lunch. You probably need to let the door company know about the spots. We outsource our doors too, and from time to time get contamination on them.

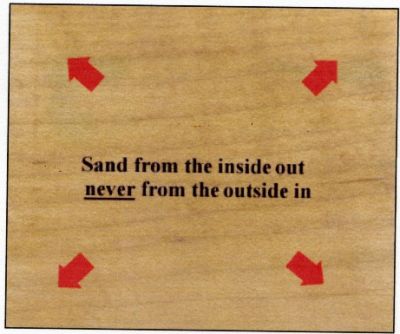

I always try to lightly sand the doors before they go into the finish room. Invariably, if I'm not in the shop, that step gets skipped. On a couple of occasions we've regretted it. I put the word out that the next guy who does that will get water-boarded

From the original questioner:

Contributor J - I let the door company know and they are trying to figure out what might have happened. I will know more when we finish an alder set that was delivered at the same time. We will lightly sand prior to the staining.

From contributor A:

I have seen the residue from adhesive tape cause that.

From contributor R:

The only time I've had that problem is on VG fir- where pitch was involved. It doesn't make sense with maple though. It took a couple of days but eventually dried.

From contributor S:

Try swiping the affected spots with a clean cloth wetted with naptha and then letting it sit for an hour. Don't rub the spot or the finish will come off. See if that does the trick.

From contributor M:

If the naptha trick doesn't work try a rag just dampened with water (not soaking wet) and just lightly wipe over the shiny area. It usually will dry in a half hour or so.

From contributor E:

This appears to me to be an "amine blush" problem. These blemishes seem associated with defects in the wood that may have been filled with epoxy. Most epoxies will leave a waxy layer at the surface as they cure. This layer (called amine blush) will seriously retard finish curing. With heat and time you may get it to cure but it is unimaginably slow (days to weeks).

It can be prevented by wiping the blush away with a damp rag (previous to finishing). Sanding may remove it but it's best to use the damp rag treatment first as the sanding could just smear it out. I have had some experience with this type problem. Experienced epoxy users (boat people mostly) are familiar with this.

From contributor O:

It could be a lot of things. Tape adhesive as suggested, oil from chips, silicone are all things not allowed anywhere near my veneer parts and doors. There are even times where the doors are sanded and we still have a problem. Some soaps will also have the same effect as they are oil based.

I've had the same problem so I tried talking to our supplier about how they handle the doors during packaging and shipping. They stated it could not be them. To find out where it came from we started the process of elimination. I had my sanders/finishers wear gloves. That did not work. I then had my receiver wear gloves and still no change. Then I was able to get my supplier to ask the wrappers/shippers to wear gloves. I have not had a problem since.