Frameless Sink Base for a Farmhouse Sink

Tips on constructing the base cabinet for a farmhouse sink. January 13, 2009

Question

I have to do a frameless sink base for a farmhouse apron type sink, a small Rohl fireclay sink, 24w x 18d x 10h. Top edges flat, to be lapped by granite top for "undermount" look on sides and back. The job is all frameless. The sink specs give dimensions as approximate, saying sink should be on hand before cabinet is built.

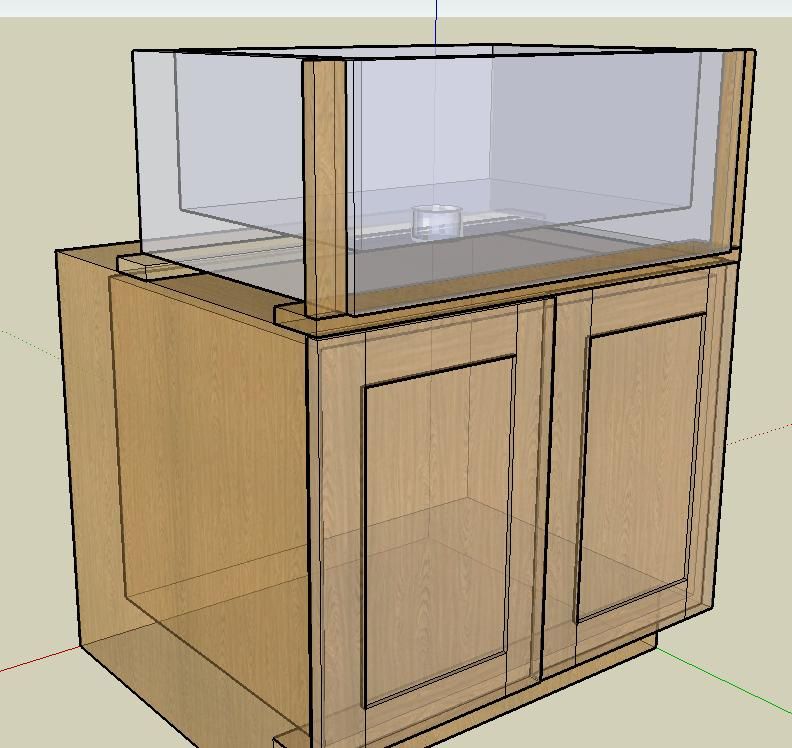

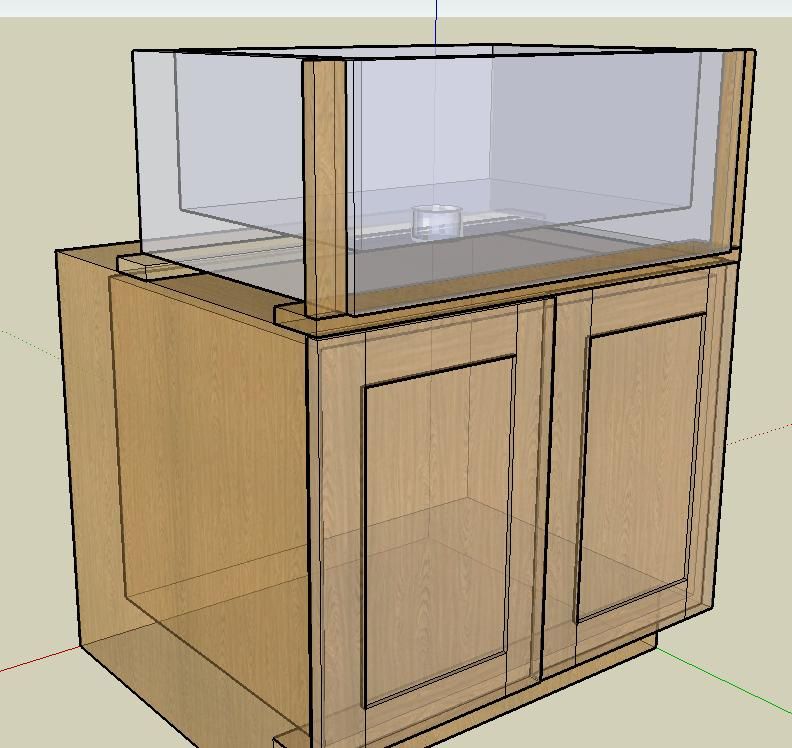

I am thinking of doing it like shown in the picture below. A simple full-top box below, wider than the sink, with 3/4 thickness species stock to do the crossboard under-seat and stiles, both mounted to be flush with face of doors.

The sink has rounded edges all around the corners and bottom, so the stiles will be coped to join tight to the sink. It is mounted so that its apron front is proud of the cab fronts, and just about flush with the stone countertop edge. Suggestions for a better way are greatly appreciated.

Click here for higher quality, full size image

Forum Responses

(Cabinetmaking Forum)

From contributor J:

I've done a few, frameless as well, and I make the inside width of the cabinet the width of the sink + 1/8". I run my sides full height (30.5") and run a full deck for the sink to set on, set down the same height as the sink for undermount. I never cope the sink - they're so irregular, they look better to me sitting apron proud, in a square opening. Besides, I've heard the clay sinks expand when hot and would be concerned with it breaking if it was tightly coped.

From contributor A:

Do not - and I repeat, do not - build that cabinet until you get that sink in hand.

From contributor R:

We do it similar to your picture but turn the bottom rail on edge. The bottom of the sink won't be flat and you will have to trim it to fit.

From contributor D:

We build the cab about 3" wider than the sink, then build a three sided frame the same width as the doors. The frame has 1 1/2" stiles that can be fit to the sink. Place bumpers behind the frame to keep the face of it flush with the face of the doors and you are all set.

From contributor E:

I've only built one frameless and it was basically the same idea you're thinking of. One other thing to look out for is the top of the sink. Mine was off by close to 1/4" and was a real pain to fit to the countertop. The bottom was flat enough, but I didn't realize the top was out until I tried to fit the top. And because it curved up at the center of the sink, I had to carve out the bottom of the countertop. So like the others have said, don't do anything until you have the sink in hand.

From contributor B:

The weight for some of these farm sinks can get close to 200 pounds. Make sure that the cabinet below has some extra support built into the design. If the sink has a good flat bottom that spreads the weight across the entire top, you might be okay. Usually these sinks have a bow in the bottom that concentrates all of the weight in the center.