Question (WOODWEB Member) :

On a bandsaw mill with 30” wheels, that takes 1.5 to 2-inch blades, cutting red oak, white oak, and maple in the Northeast, what blade seems to hold up the most? Also, how many sharpenings can one expect to get out of 1.5 to 2-inch blades cutting the above hardwoods? The average log would be 22” to 29” diameter log average.

Forum Responses

(Sawing and Drying Forum)

From Contributor P:

First I have to say I am not so good in English to explain all I would like but here is a try. I have some experience, my saw has 23" wheels, we use 1,5" blades. On each blade we have a "card" to make notes about all we have done with the blade. I have blades, grinded 28 times, adjusted the set 12 times. That blade has cut about 110 logs. If you have bi-metal blades the tip of the tooth (with the hard steel) is not more than one or 1,5 mm. That means you can’t grind more than, say five times until the hard tip steel is lost.

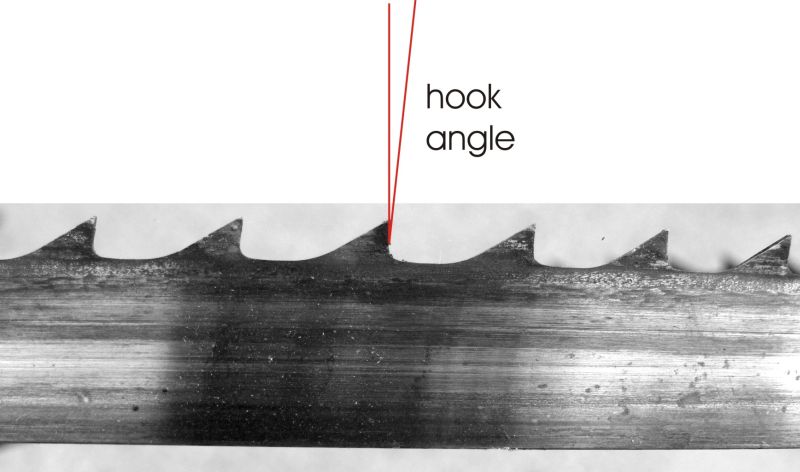

If you have wheels 30" diameter you do not have to be worried about fatigue because blades are bending around the wheels. The old books says the wheel diameter would be 1000 times the thickness of the blade, to be safe. The steel used today is better from that point of view. In my opinion the most dangerous for the blades is too high feed force caused by dull blade, wrong hook angle, blade guides far out from the log, big log diameter, to low blade tension, to small gullets.

All actions that will bend the blade hard (in the wrong direction) by the guides flanges, have to be avoided. The result of such bad handlings is that the steel in the bottom of the gullets is over stressed. If the grinding also is performed to hard, (signs of blue color in the gullets), the blade will crack/break very soon. Every point of the blade passes the guides about five times/sec. The aim point is to have the blade to cut it self-free and be so aggressive that it nearly feed itself. In such good case the blade will go straight (between the guides) through the cut and the steel in the gullets will be more happy. The alignment of the saw and how the blade tracks is also important things to take care of to give the blades a long life.