Glass Table Top Connection Methods

Thoughts on how it might be possible to structurally fasten glass to wood for a custom table design. July 29, 2014

Question (WOODWEB Member) :

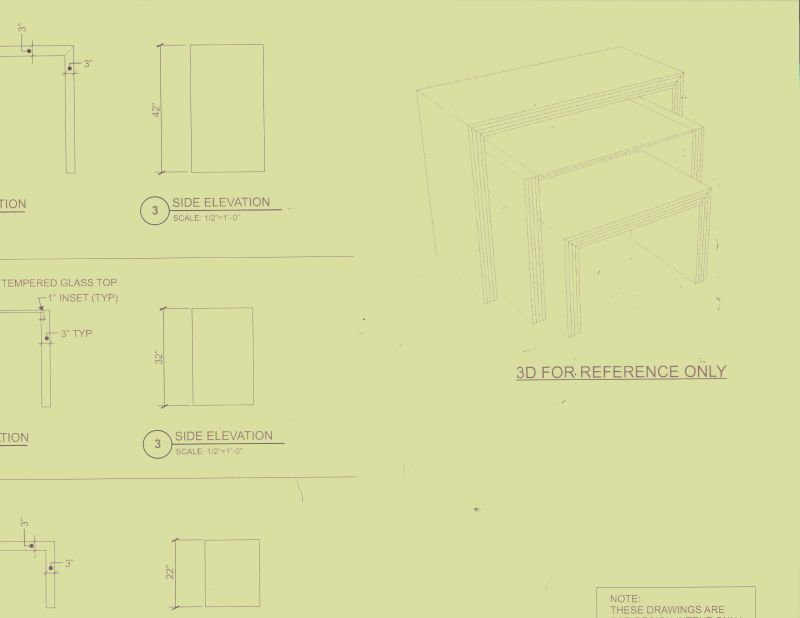

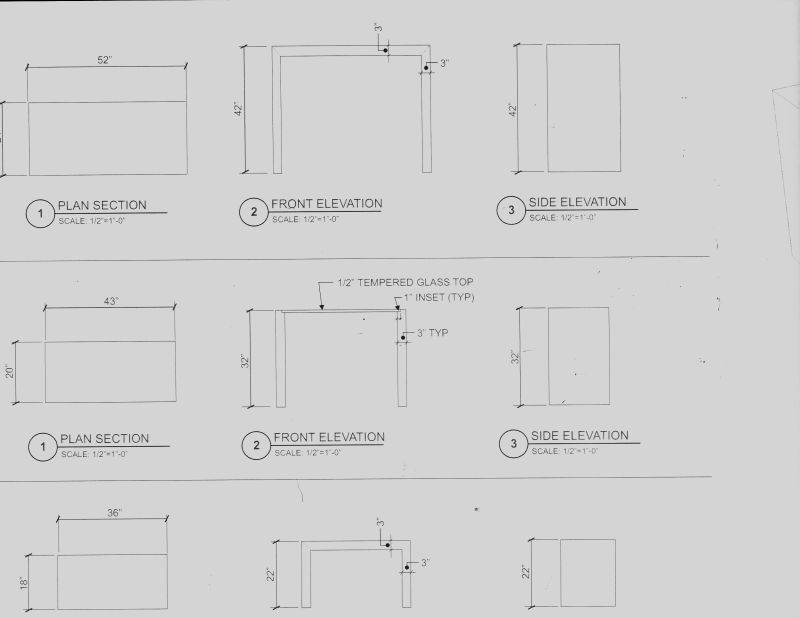

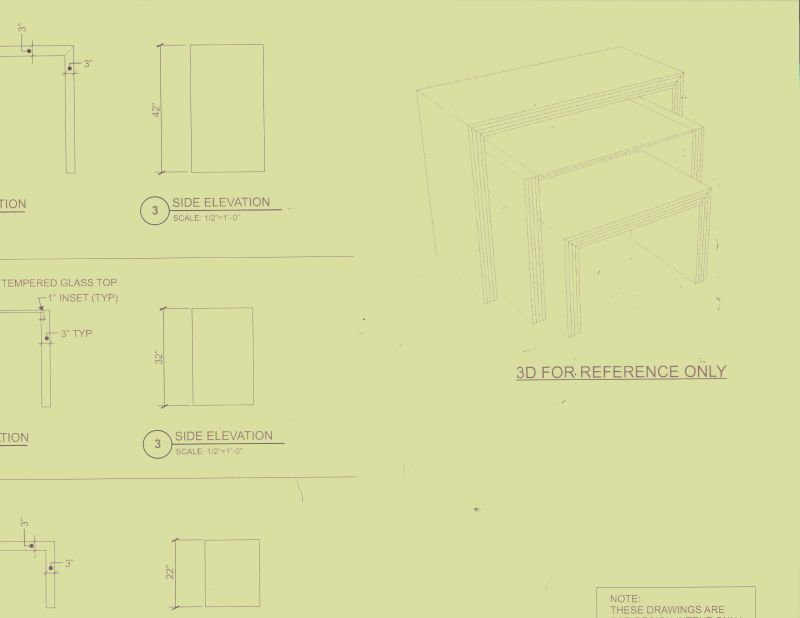

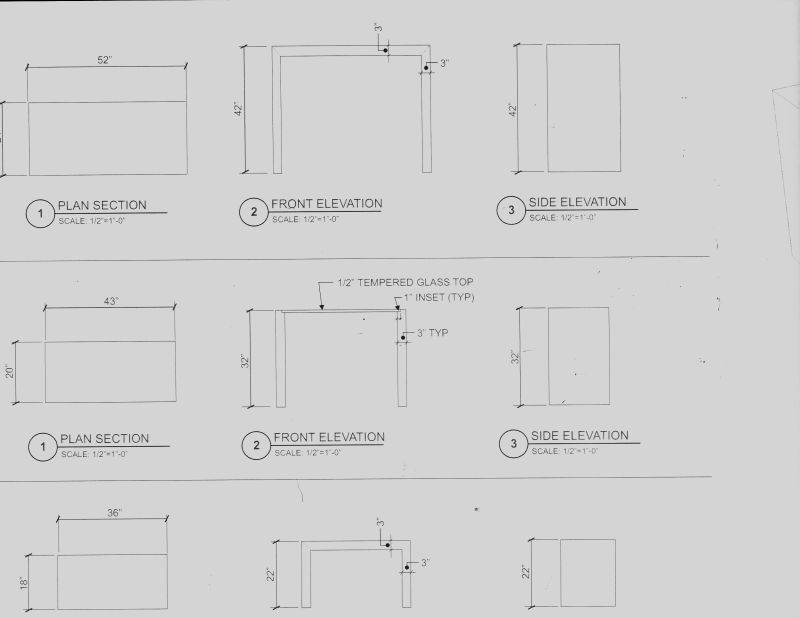

I have nine sets of nesting tables to make. Each set has three tables and the tables are made of maple laminated together. The middle size has a 1/2" glass top table, maple legs and no stretchers. My question is how to attach the glass to the maple legs. I am thinking of having the glass company drill and countersink holes in the glass for bolts to attach to the legs. Any thoughts that you guys have would be appreciated.

Click here for higher quality, full size image

Click here for higher quality, full size image

Forum Responses

(Architectural Woodworking Forum)

From Contributor O:

There is a reason you have never seen glass/wood tables like that - they don't work. No adhesive or any normal mechanical fastener will work to forestall the tremendous leverage on the corners. The closest I would get to it would be with a rubber isolated shock mount in a 2" thick top, with 2" or more butted on the wood.

From the original questioner:

I know what you mean. Classic case of the architect wants it this way. I just want to explore my options.

From contributor F:

I'm all for trying different things, but sometimes people do just have brain cramps! Ask the architect how he expects the glass to perform in this circumstance and if he's any good he'll realize his mistake or come up with another way of making it. Architects, (if he actually is one?), are supposed to understand materials and structural connections. My guess is he'll just put it on you to figure it out since he has no clue.

From contributor L:

There seems to be a terminology problem. Surely they can't intend for the table to consist of two heavy leg slabs and a 1/2" glass top mysteriously attached. I wouldn't make it. I only have $2 million in liability insurance! Remember even if you get some sort of waiver of responsibility from the designer (unlikely), you're still ultimately on the hook if something goes wrong.

From the original questioner:

I agree on the section that is not correct. I am going to build the middle size out of wood just like the other two sizes.

From contributor A:

Even if you are able connect the glass to the legs mechanically what is to keep the table from breaking when an employee drags it across the flooring and hits a transition or the leg snags on the carpet?

From contributor M:

I'd build it. Well, I'd fix it first, but the idea is possible. I would use 1" tempered, and leg build-ups with very little mass. The actual bearing surface would be machined stainless steel pads, attached to the glass with UV cured adhesive. The reason that you don't see designs like this is because they're costly (not impossible) to make well, and the difference between well-made and not is drastic (the junk falls apart).