by Rick Allen at gardenofwar.gq.nu

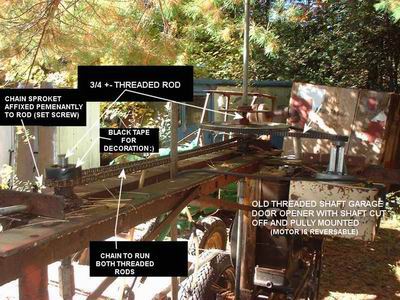

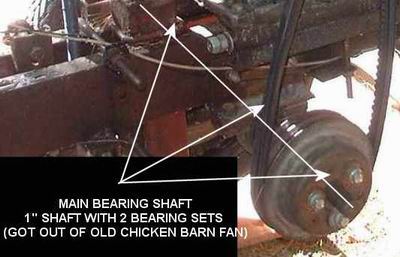

Band saw lumber mill design notes. This is not a how to. It's just some photos of a mill I built and use. If you attempt this you are on your own. I can take no responsibility for your injuries (which you will sustain on use). There are many things that can go wrong with this and either kill you, maim you or people nearby. Blades break, engines can explode or catch fire, motors can short and electrocute you. I once had a blade break and had an 8 inch section sticking out of the shed you can see in some of the photos. (build a blade guard) But it can be built and used to good effect if you are real careful. Custom blades can be purchased in most cities - look in your yellow pages. No plans are included as there can be none with a junkyard sawmill - it's a case of find it and weld it on. Read and use at your own considerable risk.

Comment from contributor A:

I had a machine shop build a bandmill of my own design, similar to this. The following comments explain what I wish I had done.

1. Factory made steel bandmill wheels would not have cost any more. Machining of auto wheels to run true was expensive. Also, machining the proper radius on the tire was a problem.

2. Rails and log bunks should be at least 1/2". Costs only a few dollars more. You will never get a good cut unless the tracks are straight and true. I use 16 leveling bolts to keep my frame true.

3. Four post, not just two.

4. Better to buy Suffolk saw guides than make your own.

5. Drive arbor should be at least 1.5" if extended over 5 inches.

6. *Raise the bed frame* at least 18 inches high. You may want to add hydraulic dogging and log turning at some point.

7. Some form of hydraulics to raise and lower the saw head. I use a worm gear winch and it is a real pain and very slow.

8. Bolt everything together *first*. After it is "true", then weld. Even the major firms are now doing it this way.

9. If you are cutting over 14" wide, it might be best to use a 20 HP gas motor or an electric 10 HP industrial motor.

10. For your posts, pick up used hydraulic cylinders (they get thrown away). A little design rework and mounting in square tube frame sections will do wonders for your saw.

I should mention that I am not unhappy with my saw, as I can cut 1/6" veneer 12' wide by 18' long. I cut mesquite, a very hard wood and this type of saw does quite well.

Should you follow the ideas above, you will find yourself with a $20,000 saw for less than $5,000.