How to quartersaw

Sawyers share details and pictures of their preferred methods. May 17, 2003

Question

What are some different methods to cut logs for quarter sawn lumber? I can see where some methods would produce a lot of waste and some would be very labor intensive.

Forum Responses

(Sawing and Drying Forum)

If you follow the link below, you'll find a thread with pictures of how I do it. The critical thing is to take the time to get the pith parallel with the mill bed. If you have a log with a lot of 'flair' you should take off some flat-sawn shorts until you have a perfect parallelogram. After that everything works out quite nicely. Can't do much about the waste, I'm afraid.

Quartersawing My Way

On big logs I rip the log into quarters with the chainsaw and then cut from the bottom on each 1/4 the old fashioned way, flipping after every cut. WM has another way that is very productive but you don't get 100% 1/4 sawn lumber. Some comes off bastard sawn. Check their website for info.

Go to the top right where we have a search option. Put in the word quarter and you will get a lot of suggestions. (Do not use quartersawing, quarter saw, etc., as the word "quarter" will find all of the references and not worry about spelling variations.)

Gene Wengert, forum technical advisor

From contributor A:

I do it like this and also produce rift and flat sawn from the same log so that I do not waste anything.

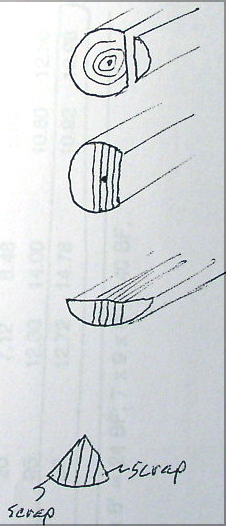

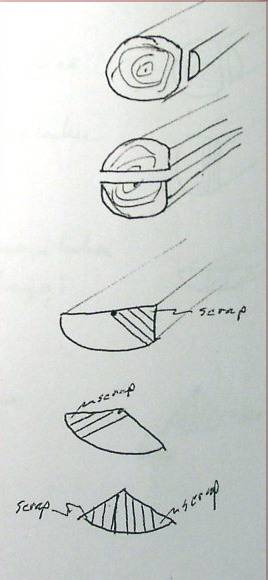

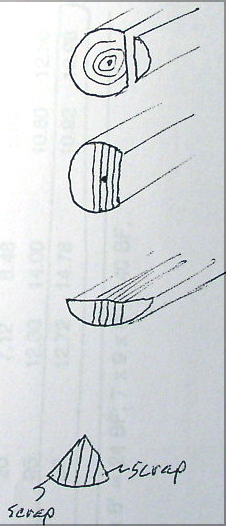

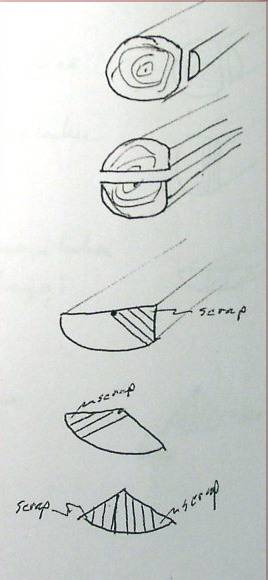

This is a sketch of how to saw 20" and larger logs. Slab heavy on one face, then slab heavy on the opposite face. Saw the cant into q-sawn lumber. Saw the center of the slab into q-sawn and the triangle edges of the slabs with some waste.

This is the technique for smaller logs. Take off a small slab to obtain a flat surface (for safety when holding the log), split the log in half, saw each half from one edge (at an angle) until the center is reached, repeat for the other edge, then rotate the remaining triangle shape piece and saw (with some waste).

Gene Wengert, forum technical advisor

I only quarter saw to get flake. The top board in the picture has rings at 30 degrees off vertical and as you can see, no flake. The bottom board has rings at 90 degrees and plenty of flake. Both from the same 28" burr oak log.

At what degree do you start to lose the flake? Are there some species of white oak that show more flake than others? Same question on the red oaks.

Quarter sawing for flake has been sort of hit or miss for me, so any help will be appreciated.

I quarter saw for the flake or fleck, whichever it is, also. Like you say, the flake is best at 90 degrees from growth rings. I think this is because the saw is cutting parallel with the rays creating long flakes or flecks. As we move away from 90 degrees they become shorter because the saw is going through them at an angle. White oak makes beautiful fleck because the rays are so thick, increasing the chance of hitting them and staying in contact with them. I have heard that sycamore has pronounced rays too, but have never sawed any. Stability of the wood is another good reason to quarter saw. I have noticed that sticker stain seems to go deeper in my quarter sawn red oak than other species. I could be imagining things!

From contributor A:

To tell if a log is going to produce good Q-sawn lumber, look first at the bark. Straight bark means the rays run straight from the outside to the middle of the tree. Then look at the rays. The thicker and longer they are the more chance you have of hitting them. Here is a photo of a red oak with good rays. They are wide and straight and run solid from the outside to the middle. Looking at the ends of the log will give you good clues as to Q-saw or not. Most of the time, unless it is a 30 inch log, I Q-saw the middle 4 cuts and rotate and make 4 more cuts, then flat saw the pies so as not to waste much and get the best and widest Q-sawn boards.

From contributor L:

That makes sense to me. 4 cuts and rotate for 4 more cuts. I am going to try sawing a log your way next time. Thanks for the tip!

Contributor A, in your first picture, after you've made the three cuts from the center of the log, what do you do with the big top and bottom chunks? Do you stand them up 90 degrees from the original orientation and saw through?

From contributor A:

Yes, I will rotate the whole thing 90 degrees and pull the middle boards out and then saw it again. I will have 4 pies and 3 or more boards. In larger logs I cut the tip off the pie till it is 3 inches wide, then put the tip down and flatten the back. Rotate 90 degrees and saw some and flip and then saw out 3 or 4 boards. In small logs I just clamp 2 pies in and flat saw to the deck. You will get flat sawn and rift sawn lumber but no waste.

How much bow in the log do you get when cutting so deep into the log on your first cuts? Kind of hard to manage stress by taking cuts off all sides when you go straight to the middle.

From contributor A:

Often I get none or so little it does not matter. I have cut sycamore and it really jumped up. The bigger the log, the less it moves.