If your talking a one man shop making a range of products from cabs, to small scale production items from solids, to furniture. Is a small one man shop wasting money investing in a decent 4x8 given your wearing all the hats? Programing, drawing, feeding, assembly, and so on? The one man is doing the same thing with multiple pieces of equipment currently so would a CNC be worth looking into or just a waste of time?

The variables are understood, just asking in broad/general terms.

From contributor Br

Hi

there have been tons of questions like yours on this forum and opinions vary. I can tell you that for me it has been a game changer. It did take me a short time to learn the software (VcarvePro) as I was pretty green. their training videos are great. But now that I'm up and going its been great. doing all sorts of jobs with it that has broadened my range of work. I'm doing alot more commercial work now as the residental has been a headache. If you're gonna do it, you will not regret a 5X10 over a 4X8. Good Luck , Brian

From contributor Mi

I know of two shops that are 1 or 2 men operations that are extremely successful. They wouldn't have made it without their industrial cnc machines. Repeatability and speed along with good tooling decisions are what made it all happen. They both survived the recession and are thriving.

From contributor B.

No question about it a CNC is a great addition to a 1-man shop. A CNC will increase your volume, product variety and, for many, the enjoyment of what they are doing. I've had a CNC router since the late 90s and I still get a kick out of watching it cut things out.

BH Davis

From contributor ca

no, not at all

From contributor Ni

Safest thing,,,grab an old school holt her supercut panel saw ,,,and when your sales increases invest in a small cnc,,,sometime a cnc causes more headaches than Anything,,,you can easily spend all day fixing a safety mat error,,,maintenance on the chiller and vacuum,,,and the software,,,no doubt our weeke and our weeke and untouchable (when they run)..but sometimes our supercut panel saw is just ready to go

From contributor ja

Worth a look, good due diligence will pay off in the long run.

CNC is a tough move but it is not impossible, go see shops like yours with them. I have a good two to three visits a month, most all of us are pretty smidgeon with our machines and are not afraid to show them. Me I am still amazed I got this far. up until 07 I swore I would never own one and since I have had 6 and have two now.

IWF is this August. My crew will be helping a favorite Product We use extensively (Star hangers) as the owner is a local guy we all want to help. basically with the economy rockin the show should be big and all the players will be there at the same time.

Give that some consideration

From contributor ja

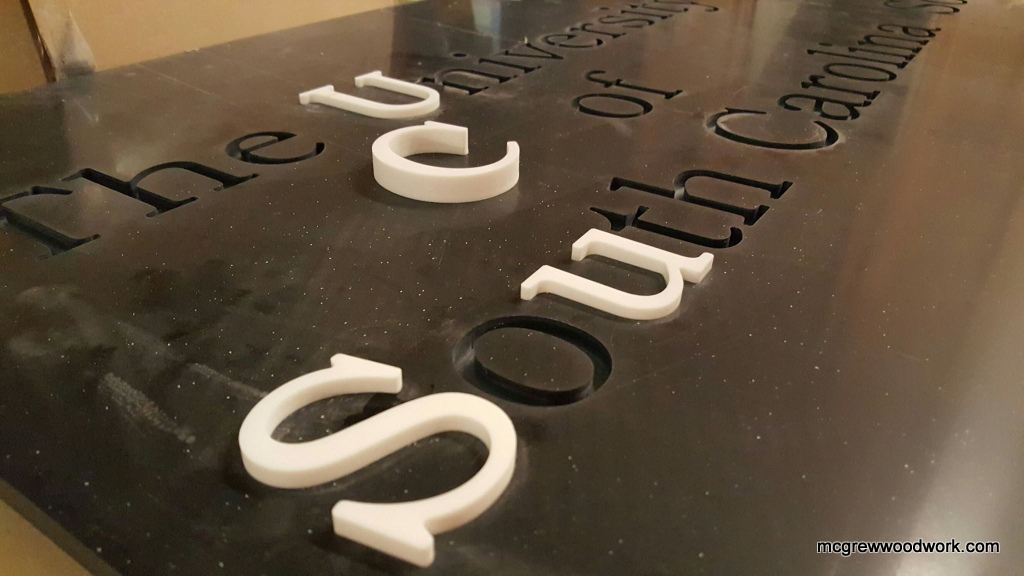

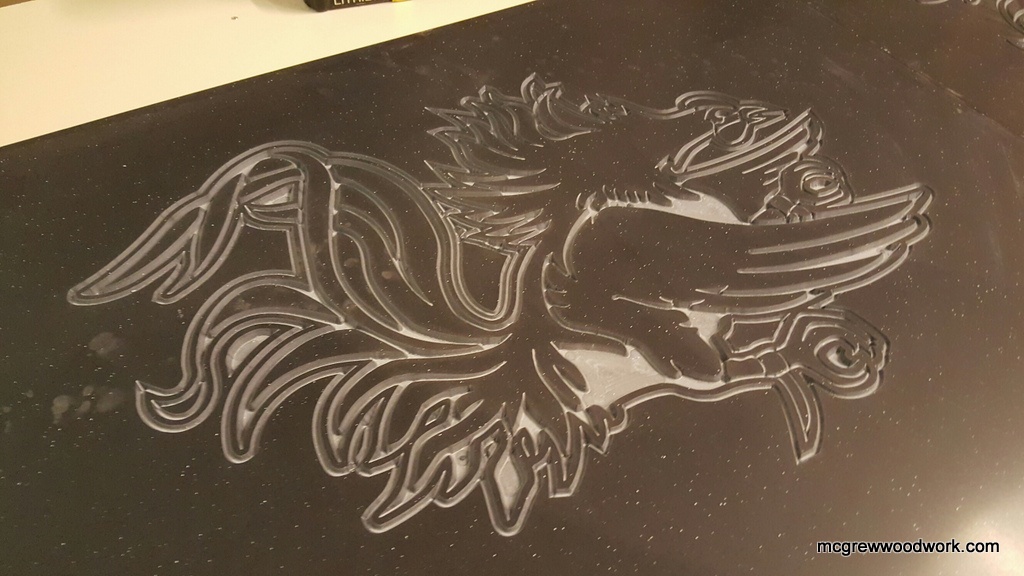

It is Nice to be specified for High custom Projects

For the Colonial Center, Home of the USC Gamecock Mens and Ladies Basketball Programs

Gamecock inlay for the Colonial center, Gonna inlay the garnet today, did two methods

1) TEXT - Vectric Aspire inlay toolpath feature, do the male first, then the female, you can adjust needed offset this way for a great fit.

2) Vcarve with epoxy colored fill and surface polish

From contributor Dr

Had a CNC before a table saw...

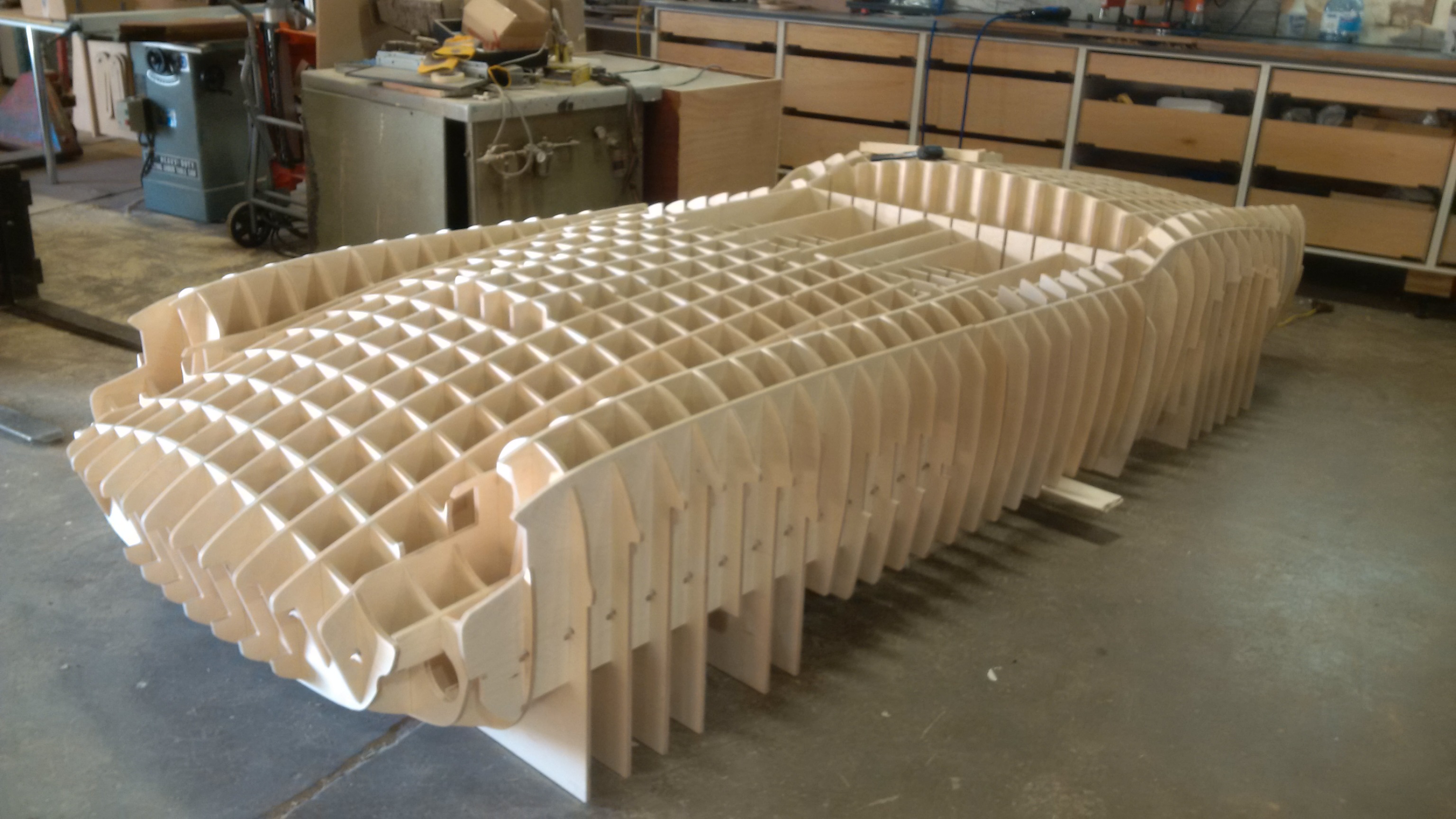

Can't do stuff like this with out it.

From contributor ca

"sometime a cnc causes more headaches than Anything,,,you can easily spend all day fixing a safety mat error,,,maintenance on the chiller and vacuum,,,and the software,,,no doubt our weeke and our weeke and untouchable (when they run). "

OMG are you kidding me ? Set up a maint program, make sure your air is clean, and check all the connections on the machine once a quarter. This elimantes 99.9% of all problems

From contributor B.

My CNT 900 has broken down once in the 10 years I've had it and my machine before this never broke down.

The CNT 900 break down turned out to be a solder spot on a circuit board on the computer end. It had been rubbing on a plastic box housing and broke. A minor fix that kept us down for a couple days.

Two days down in over 15 years of significantly increased production. I'll take that any day !!

BH Davis

From contributor Ma

Thanks for all the input guys. Looks like its time to start figuring it out. Much appreciated.

From contributor ed

Just me and a part timer. I wish I had bought a router a long time ago. Have had mine for 18 months now.

One benefit I really can't put a cost on is my health. A lot less wear and tear on my body. I don't ache at the end of the day. After cutting, drilling, dadoing a big job.

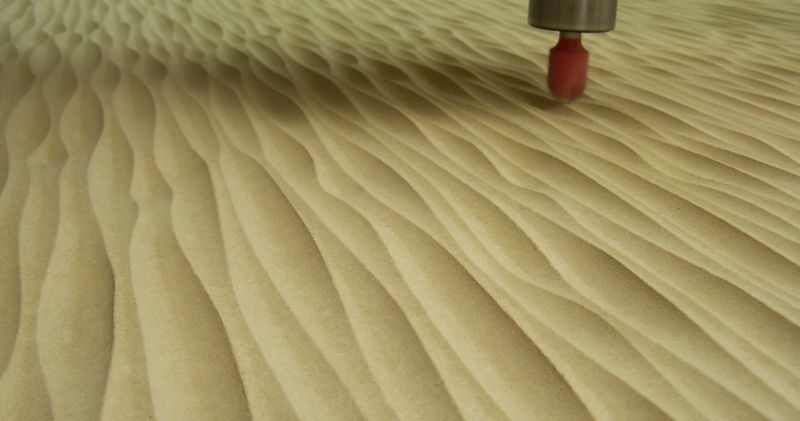

As others have said it opens new job opportunities. Just finished one piece textured, trapezoid shaped window and door frames.

From contributor ri

In a one man shop, a cnc sitting in the corner waiting for you to get off the phone or back from a client visit, is an expensive investment. Now if you have another shop cutting your parts, you will be making money while you aren't even in the shop. And, you didn't have to make the investment in machinery. I feel the smart small shop owner today is outsourcing as many of his components as possible. Especially "cabs" as you mentioned. When you have someone else make your parts, you know exactly the time and cost of the parts and it makes estimating a dream.

From contributor Ga

From my experience of investing In a router 2 years ago is that it's not so much the router to be worried of but what software your going to run. Which software will give you the best support and training ?

Also, have a plan for the router before you get it . Goals of what you see yourself cutting with it . My problem was I bought ours for a large church door and window job, but I lacked a plan for after that. You'll also be surprised at what new elements you can easily add to your projects for added value

Having a cnc is great, it is like learning woodworking all over again but it sure is fun . Best of luck

From contributor Je

If you think out your cuts you can really save time as after you cut the first sheet you can start assembling while the next one is cutting. you do not have to stand there and watch it cut but be close enough to hear it and see what is going on

From contributor Ma

Ok.. the big plunge. Bank involved... business plan in the works, vendors are quoting. Here we go. Thanks again for all the input. This place is amazing.

From contributor ri

Make sure you are getting the whole package quoted. Software, dust collector, vacuum table, collets, etc. It takes thousands or dollars more than just the machine.

From contributor Ma

Thanks Rich, I think Ive got most everything other than tooling outlined. Working out the in-shop modifications as well. Will be a bit of a process for sure.

From contributor He

Getting a CNC was the best thing we ever did! We are a 3 man shop and the is absolutely no way we could turn out the volume with out it..

We got ours used like Dropout has, no bank= no debt.