Question

When my compressor turns on it makes a noise in the copper line. What is the best way to remedy it? I am thinking about cutting the line after the compressor and putting in some kind of hose or flexible joint to act as a shock absorber.

Forum Responses

(Dust Collection and Safety Equipment Forum)

From contributor G:

I used a piece of soft copper tubing that I made into a 3/4 circle to attach it to my system. I did it because I didn't want to sweat a bunch of fittings to get it from the compressor to the start of the air line. I don't have a clue if it reduces noise though, because that is the way it has always been. I can hear the compressor filling the lines when I am in my spray room 75 ft (of line) away. Just a hissing sort of sound as the pressure builds.

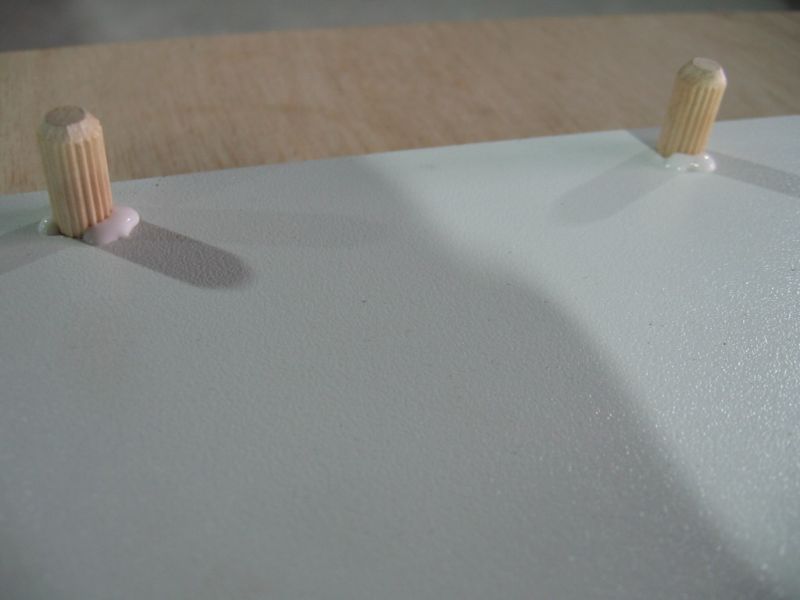

I remember when I started doing a little research into compressor setups it was highly recommend to not hardpipe to the compressor because of vibration issues. The funny thing is I had a tough time finding anything off the shelf for that purpose. I ended up going to a hose supply place and picked up a short length of hose for a couple bucks. Just make sure the PSI rating is high enough.