Joinery for Mitered Corners

Suggestions run the gamut: lock miters, splines, dowels, floating tenons, pocket screws, and butterfly splines. Take your choice. October 19, 2013

Question (WOODWEB Member) :

I am going to make a solid walnut cabinet with mitred corners. I plan to make an initial beveled cut on the tablesaw and then clean it up with a router with a straight bit on an angle. Then I will join with biscuits. Is there another way to do this that is more efficiently?

Forum Responses

(Furniture Making Forum)

From contributor M:

Forgo the router step. I also use floating tenons as opposed to biscuits.

From Contributor C:

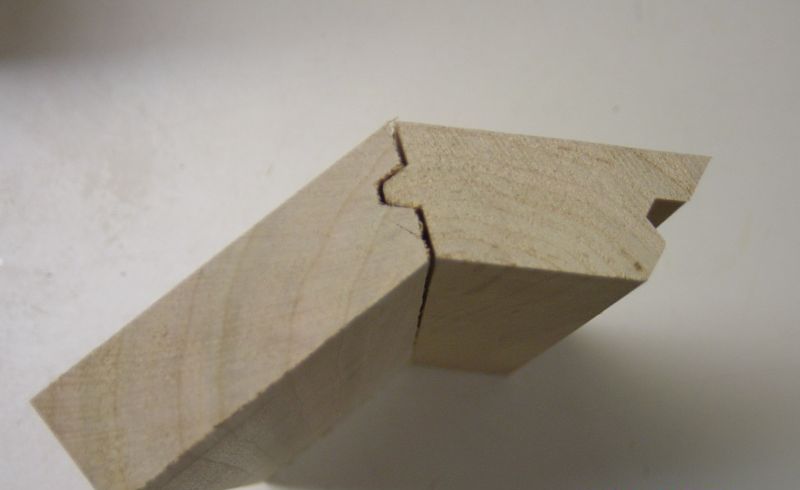

There are router bits available with a "lock miter" joint in a 22.5 and 45 deg.

bevel.

Click here for higher quality, full size image

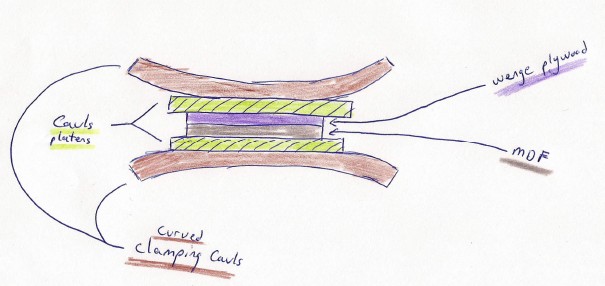

Click here for higher quality, full size image

From Contributor D:

Another way is to spline the joints after you bevel the 45. While the blade is still at an angle adjust the fence and height of the blade and cut a slot or the splines.

From contributor R:

You can use pocket hole joinery. One piece is cut to 45, the other stays at 90. You have to trim back the 45 piece with a hand plane to make the corner, but it works very well if holes inside the cabinet don't bother you. I have done a couple and even covered the pocket holes with a thin trim board inside the cabinet. You don't need to make clamping cauls with this method either.

From Contributor H:

All good ideas - especially the lock miter or the full length spline. Wafers are a weaker second choice.

From Contributor B:

I use a construction drill (Maggi 2332) to bore for dowels on miter frames. It's a fast and accurate way to join mitered panels or frames.

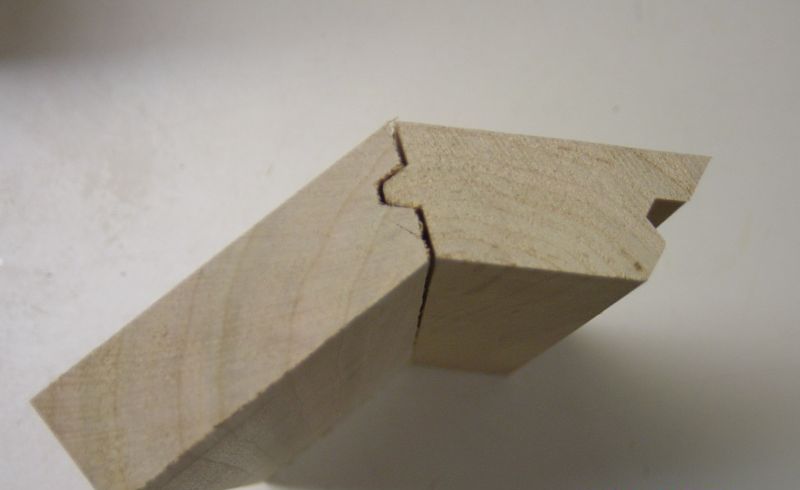

Click here for higher quality, full size image

From Contributor O:

I would have to agree with floating tenons for the best strength. I like biscuits and they are strong but they are small and scare me, especially on something like a cabinet door that gets slammed repeatedly. Set up a 1/4" spiral bit on a router table, make a tall back board and some stop blocks and you can knock them out in no time at all. The pocket screw idea, while a noble attempt, is a poor choice. He wants to 45, not butt them. The finished product looks better and more professional. Now don't get me wrong I use pocket screws on every cabinet box I build. But doors are one of those items you just need a router bit set for to do properly. Pocket screws are ugly, even on the inside of doors (in my opinion). They do look nice if you use contrasting plugs and place them strategically. I have completed some projects like that.