Question

I am having a problem jointing straight knives. The knives are 6 wing carbide. The moulder is a Hydramat 23. The knives are checked for grinding accuracy before they are run. During the jointing process, the knives end up with a smaller cutting circle on the side the jointer indexes on. How do I avoid this? We do not have this problem in high-speed steel applications. The jointers have been checked for parallel.

Using a straight stone in a profile jointer does not seem to work very well. Is the stone too hard or soft for the application?

Forum Responses

It sounds like you need a harder stone, but be careful since you need to hold a minimum joint to maintain top quality. Check the things listed below, then call Weinig for help.

1) What type of carbide knives are you trying to joint? Supplier? Braised Tip? Double-Back? Straight? Spiral?

2) Are you rough grinding, then finish grinding at a lower clearance angle?

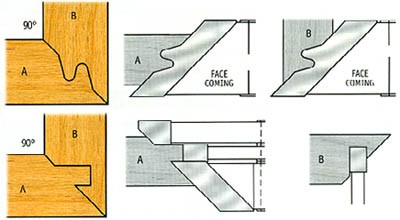

3) What back-clearance angles are you grinding?

4) What tolerance of concentricity from knife to knife are you grinding?

5) What is the measured diameter of the ground tool at both ends? (measured before jointing)

6) Are your jointers set to index in at both ends of the stroke, or just on the inwards stroke?

7) What type of jointstone are you using?

There are other possible solutions. Why are you using carbide? At present, new knife materials, which are easier to joint and grind, are being developed that may replace the need for carbide in many applications.

Dave Rankin, forum technical advisor

If you are checking true on your moulder and it is square, you may also want to check your grinder for true.