by Dan Rudusinovich

One of the most common questions my customers ask is: "How do we make sure that our saw is cutting square?" In this article, I'll explain the easiest way I've found to verify that your saw is cutting correctly. My methods apply to sliding table saws, vertical panel saws, table saws using miter gauges, and others.

When the fence is perpendicular to the blade I use a "five way cut method" to check the accuracy of my saw when the material is transferred through the blade at a 90 degree angle. This method can be used with a miter gauge on a table saw, a sliding panel saw, or a vertical panel saw when the blade travels through the material and the fence is stationary.

Start with a piece of material about 4 foot square and at least 5/8" thick (to give the test piece some stability). In a clockwise rotation, consecutively number each of the edges.

Start with the right hand edge at #1, then the bottom with #2, left hand edge with #3, the top with #4, and the right hand edge again with the number #5. Below, I've listed the steps required to check the accuracy of your saw. Be sure to rotate the test piece in a clockwise direction.

Step 1: With the #4 edge against the crosscut fence, cut off an 1/8" or more from edge #1. Then rotate edge #1 and place it against the crosscut fence.

Step 2: Cut off an 1/8" or more from edge #2, and then rotate edge #2 against the crosscut fence.

Step 3: With edge #2 against the fence, cut off an 1/8" or more from edge #3, and then rotate edge #3 against the fence.

Step 4: With edge #3 against the fence, remove an 1/8" or more from edge #4, and rotate edge #4 against the fence.

Step 5: With edge #4 against the fence, make a 2" cut on edge #5 and mark the top and the bottom of this cut. Now measure the top and the bottom. The difference of these two measurements divided by 4 will tell how accurate your crosscut fence is. This figure should not be greater than .004 of an inch.

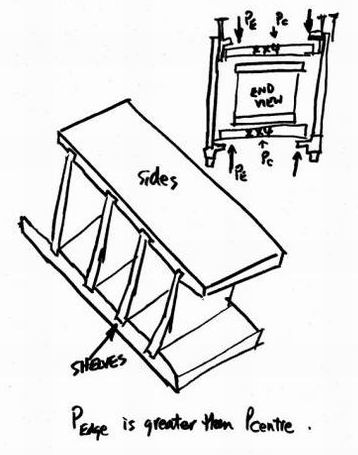

When the fence is parallel with the blade, I use a 2-Way cut method to check the accuracy of a parallel fence (when ripping stock on a table saw, for example).

Start with a piece of 5/8" (or thicker) material about 4' square (or as large a piece as your saw will allow). Consecutively number all four edges.

Step 1: With the #2 edge against the fence, and feeding edge #1 into the saw first, cut at least 1/4" from edge #4.

Step 2: With the #4 edge against the fence, and feeding edge #1 into the saw first, cut at least 1/4" from edge #2.

Measure the width of the test piece at both ends, and divide any difference by two. The result will tell you how accurate your fence is.

Danny Radusinovich is Vice President of Buckner Weatherby Co. Inc.