Making Fluted Pilasters

Detailed tips on efficient fluting, including images of a shop-made jig. October 5, 2004

Question

When making fluted pilasters, we have taken a traditional path; clamp a straight edge, rout the flute with a core-box bit, move the straight edge for the next flute, etc. Has anyone developed a better technique for fluting?

Forum Responses

(Cabinetmaking Forum)

From contributor T:

That sounds like the slow, hard way. Router table is better. Or you can get a moulding head for your table saw, which will cost more but gives a better result. I've not tried to do stopped flutes on the table saw, but I think I could.

From contributor M:

I would definitely suggest the router table. Just run it through or drop it in at specified points to make stop flutes. As you make your first pilaster, mark your router table as you move the fence over for each flute, then the next time you need to flute something you already have your spacing laid out. Also, as you are making the pilasters this way, set up for the first cut and run all the pilasters through, then adjust the fence for the next pass and run them all through again. This way saves setup time and all the pilasters are the same.

From contributor B:

I lay out my flutes so I can spin the board and do two outside flutes with one setting. Move fence and do next two inside flutes, etc.

From contributor T:

Contributor M, I used to do what you describe on the router table for stopped dados. I prefer to have a stop block at both ends indexed to the bit. Takes a bit of setup time rigging something to extend past the ends of the router table without interfering with the workpeice, but the tradeoff is that you can just butt against the stop block and drop the piece down without having to sneak up on your mark, which inevitably leaves burn marks in the end of the cut.

The other thing about this method is that it's best to move the fence for each cut and run all cuts in the same direction rather than reverse the board as Mark describes. If your blocks are off even 1/32 from each other you've pretty much defeated the accuracy of this method.

From contributor K:

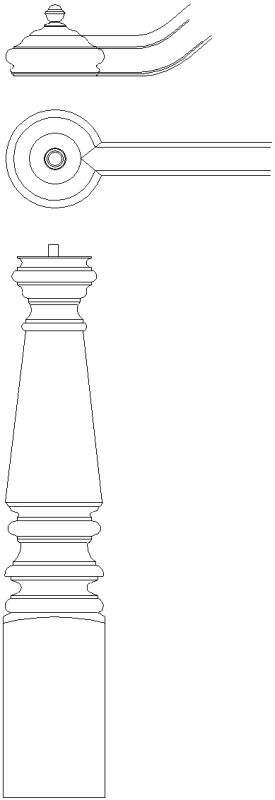

Below are some shots of my shop-made jig. I built it after trying many things, from a router table to a CNC router. The router table was too hard to do "stepped" and "stopped" flutes, etc. The CNC has a problem if the board has any twist, bow or warp - the pods can't pull it flat and your flute depth changes. You are also limited to certain lengths. I make a lot of columns, so that was a problem. My jig sits on the piece so it will follow any defect in the wood. It has worked well for me. I would eventually like to build one with some "Micro-adjustment".

The jig is just a piece of tempered wallboard with the router centered, and slots cut for two adjustable guides. It is drilled to fit two different plunge routers.

From contributor C:

Here is what I do when I am on site (trim carpenter/installer) and it is fast and very accurate. I don't touch or move the fence. I need all my fluted pilasters to be the same exact size, so I use either 1/4 to 1" (depending on what the job specs call for) MDF strips as spacers. After the first flute is milled, I remove an MDF spacer and repeat the process. The flutes will always be the same and this is very fast. If I need stopped flutes, I simply put a stop block at the end of the run and a register mark at the back. If this is still too slow, I suggest you outsource.

From contributor R:

Contributor K, what an amazing jig. I've been using my shaper to make flutes and it's a pain. Your jig looks easier to set up and use and can be made from scrap. Thanks for the idea.

From contributor C:

This is exactly why I like this site. There are great ideas here that can help speed things up and that means more money, as time is money. Your jig looks easy and simple and I will also try it!

From contributor O:

Photos of the jig are great. The blocks that hold the work piece limit how close to the end you can go with the flutes, correct?

From contributor T:

This is a great jig. As I was looking at the pictures it occurred to me that you could use it for radius work simply by replacing the stops with blocks that mate to the inside and/or outside radii of the piece.

From contributor K:

Yes, the blocks are the stops for blind stopped flutes. You can cut different size stops to start and stop your flutes wherever you want. If you want the flutes to go all the way through, just cut blocks the width and thickness of your fluted piece and use them to hold the pilasters. That way the jig will run past the ends of the piece you are cutting. Or you can have through flutes on one end and stopped flutes on the other. This jig wouldn't be for a shop running hundreds of pieces a day, but it works pretty good for small runs.

From contributor E:

Neat jig. I would consider using slots/wing nuts for sliding the stop blocks to different lengths. Also, I would have a second pair of blocks that are like ramps (with a radius, not flat surface) that would allow for teardrop stopped flutes. It's another option people like and it prevents burning when entering/exiting. Your 3/4" (?) guides should work fine when entering/exiting the cut on a slope. Just enough to raise the bit off the piece.

On the few sets of columns I've made, I have used the above technique. However, my spacing method was a pain compared to yours. Combining both concepts should render me an awesome little jig.

From contributor K:

There are a lot of improvements that could be made to this jig. I eventually want to make the base plate and fences out of phenolics. Every time I tighten those little wing nuts I vow to order knobs, but then I am done with the job, I hang the jig on the wall and don't worry about it until next time. It's the same with my circle jig… while I am using it I think of all kinds of improvements. When I am done it doesn't seem to matter that much.

The ramp would work also. I personally never liked that kind of flute, so I never offer it.

From contributor D:

When we pre-hung 40-50 passage doors a day, we did a lot of stopped flute jambs. After watching the foreman lose 3/8" of an inch off his index finger (setting a piece onto a tablesaw molder head, backing up just a bit...), we started trying different ways to improve the fluting on all counts.

What we ended up with is a dedicated table that would hold a jamb from 24" long to 96+" long, from 4-9/16" to around 7" wide. One end was a clamp to hold down the end of the jamb and to work as a stop block; the other end was moveable and lockable, and indexed for the "normal" sizings we did. Next to this clamping/work surface was a piece of 3/4" MDF with a bunch of hardwood strips very accurately milled into the face, running the 96+" length. These were all fixed for our one and only spacing - 1/2" flutes at 1" OC spacing. An offset plunge router base with an 18" steel bar rode in the tracks. Once the piece was clamped in, you could do the 4 or 5 routes in a typical jamb in a few minutes by just advancing to the next track. Take the lock off the plunge function so the operator has to hold it down, making it much easier to stop/lift without burning. It did require a bit of practice/finesse. I found it a great way to separate employees who cared (could advance) from those that just weren't gonna get it.

This setup worked for years, and is still working in several permutations. The advantages are that a piece could be completed with one clamping, nearly all variations could be handled easily, pushing the router down compensated for out of flat (the router base rode on the work piece, but was guided by the tracks), and it was easy to see what was going on and adapt.

From contributor W:

I really like the jig and all the ideas. Something I found by accident (basically I forgot to flute 2 - 94 inch stiles before I assembled the face frame) was that instead of being in a jam, I actually now had a really nice way to hold the stile to rout the flutes, since it is attached to the rails with pocket screws - just clamp the frame to the bench with the guide bar my router followed. The rails of the frame are out 90 degrees and make a convenient surface to lay the guide bar on. I simply laid out the spacing needed with marks on the rails and move the guide bar over each pass. If I did enough flutes I would make spacers for faster repeats.

From contributor V:

I use my old Craftsman RAS with a Craftsman moulding head and I custom grind the cutters from one of the standard cutters. The motor is turned 90 degrees and locked at the appropriate distance from the fence. It is cranked up or down as required. On fluted half round columns I can tilt the motor to follow the profile. The work is slid under the cutters and along the fence with a push stick. Outer flutes are done to both sides equally by turning the piece end for end, as previously suggested.

From contributor K:

Along the same vein as the above idea, there is a builder here who built a carriage for a router and mounted it to an old radial arm. He uses it for dadoes mostly, but also does fluting with it. It is a neat idea but has the same problem as CNC. If there is any cup, bow or warp, you have problems with depth, since the router is fixed and doesn't "float" on the piece you are cutting. He especially has problems with dado depth in plywood.