Oddball Crown Moulding Miters

Advice on joinery for spots where curved mouldings on an arch meet a horizontal return, and other odd intersections. December 6, 2008

Question

Can anyone tell me how they figure the miters for flex crown? I have kitchen cabinets that require arched and S-shaped crown moldings on the face of the cabinets. I need to know how to match the crown to a 90 degree return on the side of the cabinets.

Forum Responses

(Architectural Woodworking Forum)

From contributor B:

As long as your crown goes horizontal before reaching the corner, you can cut it like any other crown. However, just like any other crown, you cannot do a side return to the rear from any angle other than horizontal. If the crown is still curving upward or downward as it reaches the corner, the transition to the rear is geometrically impossible with the same profile. What you need is a stretched (taller) version of the same profile for the sides.

From the original questioner:

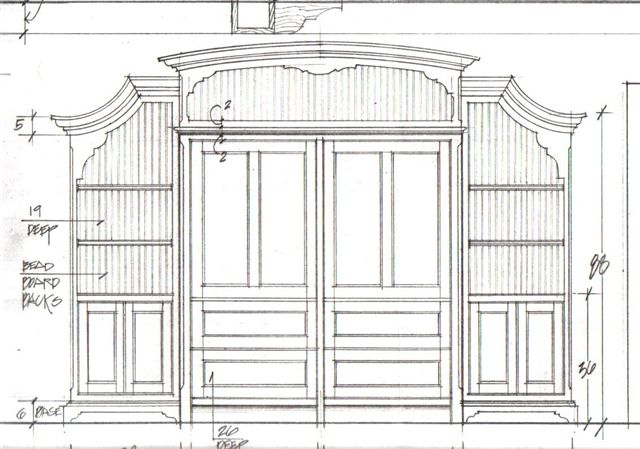

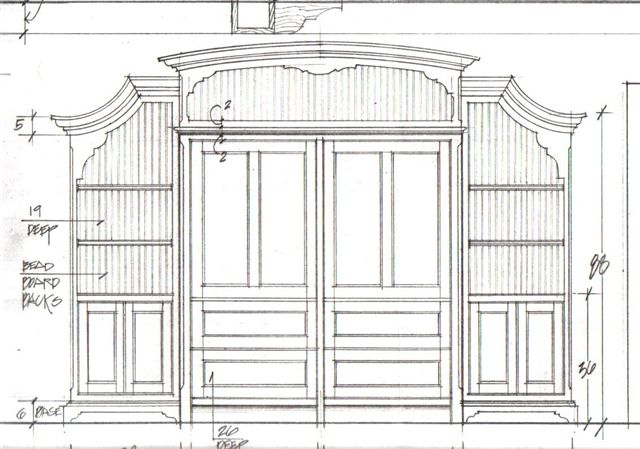

Thank you. Not being too familiar with flex molding, I've posted a picture of what I'm doing. Is there a way to make a transition from the radius crown to the horizontal crown on the two end cabinet face frames, or will the flex molding company do that for me with a template?

Click here for higher quality, full size image

From contributor B:

On the two side cabinets the crown goes to the horizontal tangent point before ending. That means you can use a standard 45 degree cut for the rear returns on those two cabinets. It is on the center cabinet that you cannot make a normal outside corner return since the crown is curving downward as it comes to the end of the cabinet. I don't think you will find a company that will produce the crown pre-mitered for you. We ship all our curved wood mouldings out overlong for fitting by the purchaser. I will, however, spend time on the phone helping the customer through the process.

There is one exception where we pre-miter crown mouldings. If the radius involved in the moulding is too tight for our overhead moulders, we can run the piece on the CNC with 3D generation software.

From the original questioner:

My issue is more on the face of the cabinets where the radius meets the horizontal, not the return on the sides.

From contributor B:

With solid wood the simplest way to make that miter to horizontal (in the same plane) is to cut a couple templates that are the same vertical projection and shape as the curved and straight crown. You can then lay one over the other at the miter point and mark the inside and outside intersections. Connect the two points and you have your miter cut. Once done correctly, trace these templates onto the backs of the crown components and duplicate the cuts.