Old-Furniture Refinishing Question: Dye or Stain? Lacquer or Shellac?

Pros discuss the differences between finishes, and share advice for thoughtfully refinishing old furniture. December 1, 2005

Question

1. What are the benefits of using a dye over a stain?

2. Should dye be sprayed on using cut lacquer or shellac?

3. Can a lacquer be sprayed over a piece previously covered with shellac? Will there be problems with the finish? I've scrubbed and sanded, but most likely there will be some remnants of the shellac somewhere.

4. If dye is used, should it be water or solvent based? Why?

I'd really appreciate your input and experience here as I've logged over 60 hours thus far on this beautiful piece and I don't want to mess it up now!

Forum Responses

(Finishing Forum)

From contributor A:

To answer your questions:

1. What are the benefits of using a dye over a stain?

A dye is clear without pigments and will not block the grain. Usually a dye is a spray-on with no need to wipe off. A dye can be faded by sunlight while a pigmented stain should not fade.

2. Should dye be sprayed on using cut lacquer or shellac?

If it is an alcohol based dye, then yes, and I think it will work with a lacquer based dye also. You cannot mix a thinner base dye with a water based finish, or vice versa.

3. Can a lacquer be sprayed over a piece previously covered with shellac? Will there be problems with the finish?

You shouldn't have problems with the shellac as they are compatible with lacquers. Rub the unit down with acetone to get rid of any wax that the older shellac may contain. You may have problems if they used Pledge or some other cleaner on it. It's hard to get rid of that stuff even with sanding.

4. If dye is used, should it be water or solvent based? Why?

For me it's a no-brainer - solvent based. Do you really want to have the grain raise after all the work you just put into the piece?

From contributor B:

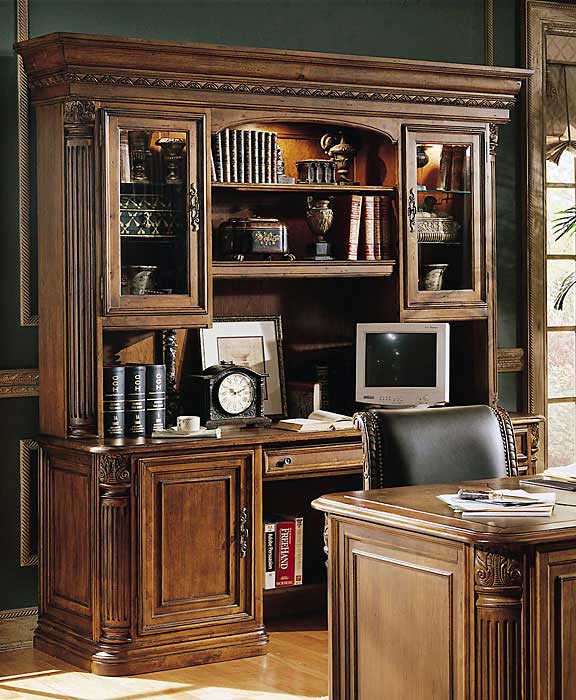

In the picture you posted, I believe I can see a few random spots of dark brown. If this is true, it doesnít matter whether you use dye or stain - you will still see them unless you go really dark. If that is the case, you still have some work to do. If itís just the lighting, then you get an atta-boy. I am going to tell you a secret that goes back 200 yrs. I'm not sure how brown you want to go with this piece but letís assume you want to bring out the grain and really make this thing pop. Find some hide glue - you can make it up fresh or use an over the counter product. For now, letís use the over the counter hide glue. Pour some hide glue in a can, and cut it by 50% with hot water. Paint it on the whole piece. The hot water will cause the solution to sink in more than if it was mixed using cold water. Let it dry over night.

Next, very lightly sand with used 320 grit paper - not too much - you just want to take it down until you just touch the wood. At this point you should be uniform in color, with any open pores now filled. If you need more color, find a water based dye. Mix it yourself and apply with hot water. By using hot water you can adjust the intensity as you want by adding more or removing it. Let it dry 2 to3 days. The gain will rise, and that is ok. At this point, hit it with a coat of sealer, wait 2 days, then sand lightly with 320. Finish with lacquer or shellac. For a really killer finish, wet sand top coat with 1200 grit. If you use shellac, let it sit for a minimum of 3 to 4 weeks to harden, then use pumice and oil to finish.

To answer your other questions:

1. It doesn't matter which you use. It depends on how you want the wood to look. I have seen Minwax stain bleach out from sunlight in just one year. To solve this you need to use a UV finish.

2. I make almost all of my own stains and dyes. I make the dye or stain with the appropriate solvent for that product for whatever finish I want to use. The only exception is if I can get a store bought one that will blend more easily.

3. You can put lacquer over shellac, however you must de-wax it first and then wash it after. If you use acetone and then lacquer, make sure you let it stand for 2 to3 days. Acetone has been known to remain in the pores of the wood and can really affect a perfect coat of lacquer.

4. Again, it really depends on the finish you are going to use and the way you want the wood to look when you are done. Either way, the grain will raise. Try a sample board and run your fingers over it.

From contributor C:

To contributor B: The hammer veneering process made me think of using hide glue as a quick and reversible filler under shellac, but I worried that the alcohol would crystallize the hide glue. Have you had any problems?

From contributor B:

I never had a problem. The only time I have seen this problem rear it very ugly head is when someone tries to use that old witches brew cleaner that contains turpentine. In this case, the cleaner cuts through the finish and lays underneath. When it dries, it crystallizes. The masters have been using hide glue for hundreds of years.

From contributor D:

I would not stain or dye that piece. I would finish it with a tinted clear coat, probably a thinned polyurethane. I would apply thin coats that are lightly tinted and build my finish and color together. I would use brushes or tight spray patterns to work my tinting up so that it had a nice look. I'd probably keep my field tint lighter than my detail areas but with a nice fade connecting them. I would do my own tinting and I would use finely ground pigments that tend to give good transparency. Colors like burnt sienna, burnt umber, raw sienna, gold ochre, and raw umber would be among my favorites. Believe it or not, black is also an excellent pigment for transparent finishes. A little black can darken a piece without hiding much grain and it gives a smoky, underglowing look. The reddish or cinnamon tints are especially enhanced by the black overtinting.