Oversize Drawer Construction

Five out of five doctors agree: heavy slides, extra slides underneath, and no guarantees. August 29, 2005

Question

I have a customer that wants me to build a drawer that is 10" high by 22" inches deep. That's not a problem. It's the 65" width that is a problem. My first inclination is to insist on splitting it in two, but she insists. Does anyone have any ideas on hardware etc. to stabilize such a beast?

Forum Responses

(Cabinetmaking Forum)

From contributor B:

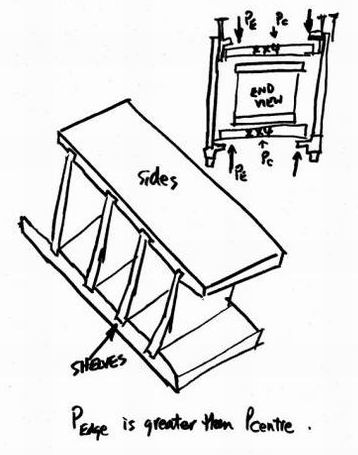

Of course, the question is what does she want to put in a drawer that big? Can you set the bottom (5/8" at the least) up a couple of inches and put some ribs under the bottom to help support it? I'd use a regular pair of full extension 100 lb guides on the sides like normal. Then I'd put a couple turned flat under the drawer, not to support the weight, but to make sure they pulled straight out and were kept in line.

Of course, have the customer sign off that they realize that you can't possibly warranty something like this and they accept it at their own peril. You can't do two drawers with one drawer front all the way across, can you? It would look like one drawer and both would pull out as one. If you can't set the bottom up, could you put a couple of ribs inside the drawer?

From contributor T:

I do sort of what Contributor B suggested. I use 1/2" bottoms in all my drawers and for wide drawers I put a slide underneath, flat. It's a bit of work getting everything lined up, but works very well. On the underside slide, I cut off the plastic retainer so you only need two hands to remove the drawer.

From contributor G:

Accuride makes a heavier duty slide that is side mounted and rated up to 500lbs, depending on the usage. It takes 3/4" of side space instead of 1/2"+. Hafele also has a rack and pinion style slide for these applications.

From the original questioner:

In doing some research I just ran across a rack and pinion, heavy-duty glide by Accuride (500lbs). They claim, and it makes sense to me, that the rack prevents the side-to-side racking. My distributor wants around $50 for a pair. I think I'm going to use a pair of these as well as build a drawer out of 3/4 material with the bottom held in a dado. The customer is an interior designer and wants to store cloth samples in it. Individually they don't weigh much, but after a while I can see it getting pretty heavy.

From contributor F:

What is the maximum drawer width that the drawer suspension manufacturer will guarantee? Most majors do have a maximum width limit. When a maximum design width is exceed the suspension racks and in the case of ball bearing slides, the balls fall out of the track and the drawer falls to the surface below.

From the original questioner:

Contributor G is correct. It is Hafele that carries the rack and pinion. The maximum width is 60 3/4", so I will have to shrink the boxes and build in a little bit. According to the folks at Hafele, the width is governed by the width of the shaft connecting the two tracks together. Without ever seeing it with my own eyes I cannot say as to whether I can modify it and add a longer shaft easy enough to make it worth my while.

From contributor P:

I would go with the side mounts and also a pair underneath. Even though the drawer will be enormous (and a real pain to insert) I don't see any reason to try to scare her. As long as the slides have enough weight capacity you should be good. The Accuride 500lb. (#9301) slides are extremely hefty, but their big problem is that they have no disconnect (we use them all the time for another application). Your application definitely requires that the drawer be removable. You could use a 200lb. capacity file drawer slide (Accuride 3640) which has a disconnect, but its insertion path would not allow the use of a slide underneath the drawer to prevent racking (which does work very well).

Another alternative is to double up with a pair of Accuride 3832s on each side, and one more pair underneath. If you make the drawer nice and hefty, with dovetailed corners and 1/2" bottom biscuited flush to the sides, mounting all of these slides will be easy and the drawer will be plenty strong. And do what Contributor T says - remove the retainer on the undermounts.

From contributor C:

One last detail - allow 1/8" at least for the drawer to settle on the laid flat slides underneath. I use the springy tabs on the accuride and pry the slide up after it is screwed to the deck. As the drawer settles it does not jam the slide.