Plywood and Lumber Rack Ideas

Thoughts, suggestions, and examples of shop-built material storage racks. September 26, 2009

Question

I am in the process of setting up a new 2500 sq ft shop and am looking for advice for plywood storage and lumber racks. I've been looking at used pallet racks online, but they seem big for my space.

Forum Responses

(Cabinetmaking Forum)

From contributor L:

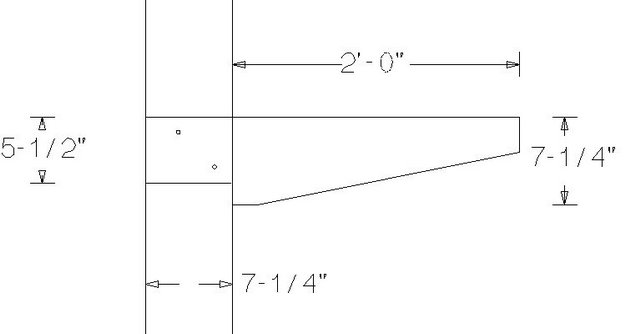

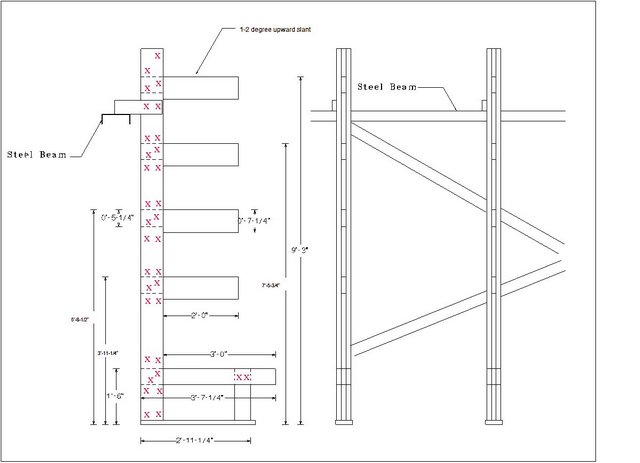

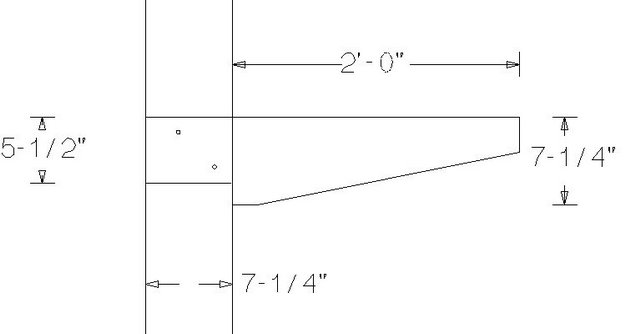

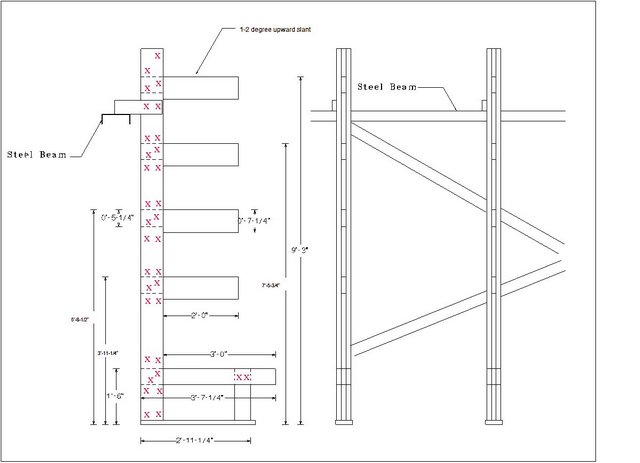

I don't have plans for a plywood rack but do have them for a wood rack. For plywood storage I made a rolling "A" frame that holds about 20 sheets.

Click here for higher quality, full size image

Click here for higher quality, full size image

Click here for higher quality, full size image

Photos courtesy of Leo R. Graywacz Jr.

From contributor J:

We like our vertical plywood rack, standing on the 4 foot end. It's constructed so there is no bottom - the sheets just slide in on the floor. We have storage on the ends of it for narrow rips and shorts too. Solid storage works well on cantilevered racks. We have a two sided one that is freestanding but close to a wall. If you have tall ceilings take advantage by going up.

From contributor Y:

If you have a forklift, take advantage of the air. We have 14' high steel cantilever arm racks that work well. Drops are stored on end in a shop built rack. Full units of board are stacked up to 5 high on the floor.

From contributor D:

I have neither the height nor space for full units and use racks slightly off vertical and off the ground enough so that only minimal bending/lifting is required.

Click here for higher quality, full size image

From contributor S:

We built this in a few hours. The materials cost about $250 and it holds about 50 sheets. Sheets further in the stack can be accessed by hooking one end of a bar clamp to the top of the rack, then leaning the stack against the other end of the clamp.

Click here for higher quality, full size image

From the original questioner:

Thanks for the input - some great ideas.

From contributor J:

As a small shop I find I use too many different sizes and thicknesses of material to use horizontal storage. If I had a bigger shop I would love to go that route, but at just about 2k sq ft, it ain't happening.

Anyway I use vertical storage for all my sheet goods. This way I can easily pull out any single sheet I need, without having to move other sheets. Lumber is also stacked vertically because of the lack of space. When I get a delivery for a job it goes on the floor where I can pick through and work it. Anything left over then gets stacked vertically against the wall. Not the most practical way to store lumber, but I can't afford the footprint a 12'+ long rack would take up.

From contributor H:

I have a 4x10x13' high metal rack set up to the right of my slider and have a forklift truck. I have about 8 dividers to store different sheet goods and can easily slide the lower level stock directly onto my locked sliding table when it is pulled back, or if I am cutting 20 sheets, I use the forklift. This racking is available used everywhere.

From contributor C:

I would put a longer bottom support on those tilted racks to ensure not creasing the sheet on narrow rails as you take it off.

From contributor G:

I just finished a rack to store sheets vertically on the 4' end, using 3/4" EMT separators inserted into 1" holes drilled into the flat sides of 2x4's, which are in turn mounted on the ceiling joists and the floor. The holes are about 1 foot apart along the 2x4's and the several storage areas are then about 2' wide each. I just lean the sheets against the tubing and pick what I want by sliding out onto the floor. I put extra tubing on the floor perpendicular to the sheets to keep the sheets off the floor itself. I find it to work very well so far.

From contributor S:

Contributor G, I have the same rack in mind to build in my shop. I like this one cause it allows me to access any sheet without having to move any others. Also, when it's on its 4" end, it's easier to scoot it along the shop floor over to the saw and then just easily lay it down on the table.

From contributor G:

It's as good a system as any I've seen posted and very strong.