Positioning Inset Doors with Euro Hinges

Jigs and techniques for tight-tolerance positioning. October 3, 2011

Question

I'm about to install hinges on a series of cabinets. Is the technique to leave the back off and install the hinges with door in face frame opening face down? Or is there a just-as-easy way with backs installed? I don't do much inset work, and am hoping to get best practice advice.

Forum Responses

(Cabinetmaking Forum)

From contributor L:

Put the mounting plates on, press the hinges into doors, snap hinges to mounting plate, done. Cabinet sitting upright.

From the original questioner:

My issue is with the depth of the mounting plates in regards to inset doors.

From contributor D:

If you're using Blum hinges and face frame inset mounting plates #175M5030.21, get the Blum Platemate drilling jig and bit. It's a faster and more accurate way to drill pilot holes into the back of your face frame for those plates. You can do it easily with the backs on.

From the original questioner:

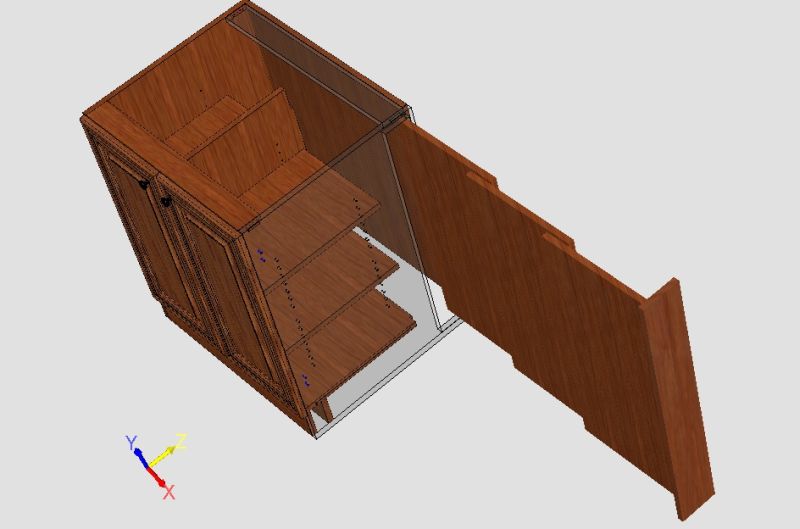

They'll be installed the same as a frameless box, just inset, as my face frame inside edges are flush with the inside case, so same as euro boxes, just better. I'm primarily concerned with setback, as with higher end cabinets with beads on the face frame like mine, the doors need to be set back almost 3/32 to make them look decent.

Form the original questioner:

I'll get even more specific. I understand the setback (see below), but when trimming a door to fit opening leaving 3/32nd all the way around, how do you calculate that when installing the mounting plates? Simply add the 3/32nd to the boring position off the door? Seems error prone with several different heights when dealing with pull out shelves in pantries and such.

From contributor J:

37mm is the typical setback for plates. That puts a 19mm overlay door 1 or 2mm out from the cabinet face. To flush inlay the door you add that 20 or 21mm to 37mm. Your drawing has 50mm where I'd think it would be 58mm. What brand/plate is that for?

From the original questioner:

Thanks. Yeah, I use 13/16 door material. 13/16" + 37-39mm will give me my ballpark.

I was hoping for tips on mounting the plates. Do any of you have jigs that you have found to be foolproof? I'm not boring these holes, simply running screws into ply.

From contributor I:

Attach hinges to door.

Clip on plate.

Place shim, for door gap, on top of lower face frame (bottom of opening).

Hold door in 90 degree, open position, on top of shim.

Drive screws.

This technique relies on being able to recognize, by eye, the correct position of an open door. After several hundred doors, it becomes second nature. If you need aide while you acquire the accuracy, use a small square or marking gauge to mark the correct depth.

From contributor S:

This is sounding a lot more complicated than it needs to be. Mock up one door application, find your center point on the base plates, and make your own jig.

From contributor J:

My system holes are all pre-bored and dead on accurate. You'll need to make a jig of some sort to position the plates. Perhaps a piece of 1/4" ply with screws just poking through to position the plate's hole centers with a tap of the hammer. The ply would be cut to index the 58mm (or whatever) depth from the face. A centerline mark on the ply lined up with a predetermined centerline on the cabinet face could be used to establish the height position. You cannot be too precise and the door cup hole indexing needs to be exact, as does the cabinet opening sizing.

From contributor M:

Most shops will have a definite standard for hinge mounting. Most American small shops choose to keep the cup a fixed distance from the top and bottom edges of the doors, let's say 3" on center. The cup's position from the side of the door will vary depending on the overlay (or for inset, the gap). The manufacturers (especially Blum) have very well documented formulas to arrive at this distance for different arm/plate combinations. You can simply rely on their math, make a test door from MDF and see if it fits as expected. The 3/32 is no big deal. I usually have 1.5 or 2mm gaps on inset doors. After you get some experience with the hardware you will be able to maintain the same cup location regardless of the application. My cup location never changes no matter if it is inset, overlay or face frame; only the arm/plate combination changes.

Once you have the location of the cup figured out, make a simple jig to drill the plate, the setback is calculated using the manufacturer's math.

Most larger shops take it to the next level and use a system to standardize the plate locations as well, but this gets complicated because you have to standardize the opening heights.

From contributor O:

What contributor M writes above is just right. I use 13/16" doors with 7/8" thick face frames as my standard. All the mounting plates holes are bored prior to attaching the face frames. Blum has this all calculated, but if you have any doubts, as has been suggested by others, set your mind at ease by mocking it up.