Pros and Cons of Pocket-Holing Face Frames

Cabinetmakers praise pocket hole joinery for face frames, discuss the occasional glitches, and compare notes on equipment. October 26, 2005

Question

I am looking to go to Ritters pocket screw system for face frames. I’d like to know some pros and cons. Once you go to the system is there joint failure, and is production time improved? Any help is appreciated.

Forum Responses

(Cabinetmaking Forum)

From contributor R:

There is no downside to pocket holing face frames. It's all positive as far as strength, speed and cost.

From contributor L:

There are a couple of things that I don’t like a whole lot with it. When you tighten the screw the face frame has a tendency to move slightly because of the angle of the screw, and this means more sanding. It leaves a hole or two on the backside of the face frame which sometimes isn't desirable. They aren't as strong as dowels or tenons, although I have never had a pocket screwed joint fail after the glue has dried unless I was making it fail on purpose.

They will speed up production of your cabinets because you don't need to wait for the glue to dry before you attach them. In most cases the hole that is left behind is of no concern. If you are building a cabinet with doors on both sides or a cabinet that will have a mirror in it this will be a problem. I use them and think they are a very good investment for your production.

From contributor J:

A vise grip welding clamp will eliminate the creep from the screw during assembly, and there will be no more uneven faces as well.

From contributor L:

I agree with Contributor D. Contributor J - you’re correct, pliers hold the joint flush. I find pocket screwed joints are not only good for faceframes, but you will be surprised the amount of other applications you will find for this system. Leo is correct however - pocket screws leave holes that may be visible. However if you wish, the holes can be plugged and sanded.

From contributor M:

I agree with the advantages of pocket boring. I purchased the Ritter system years ago and have found the weak point in the system is the boring bit itself. The pilot bit can break, the carbide tips break off and the bit itself can snap in half. This is especially true with hardwoods such as maple even with new bits. I would not say the overall look of the bored hole to be clean looking either. I would now keep my framing easel but would switch over to the Castle pocket boring machine. It is designed with routers and the cut is very clean. Most of the new shops in my area all have the Castle machine.

From contributor D:

I've been using the Kreg Pro unit for 2 years now and I am still using the original bit. I bought 2 Pro units thinking that they would wear out fast and I would have a backup one just in case. Well it’s sitting on my shelf collecting dust. I've bored everything from pine to hickory with it and it is still sharp. Now when it comes to hickory the face frames tend to split and the heads of the pocket screws tend to twist off. I always have to run a small drill bit in afterwards to stop it from splitting. I love the pocket screw system, and it saves me a lot of time in production.

From contributor R:

We've had the Castle machine for a long time. It gets used to joint all sorts of things - mostly panels as we don't do face frames. I'd buy the face frame clamp table if that was my main use. They also make a production grade machine if you are going to run it all day long.

From contributor B:

I couldn't be happier with my Ritter drill tub and table. There is no shifting if the joint is clamped tight. I'm only on my 2nd bit after 16 months, but probably should change out at least the pilot bit regularly. As for bit breakage, I got over a year on the last one. If you buy the Castle, I recommend getting a 3/8 rough mill bit, it'll cut faster and last longer.

The Castle machine is great. When it’s used with a FF table, joints come out flush every time. I've had mine since '88, six drill bits, three router bits, and one drill router motor. We find new applications for the pocket holes all the time.

From contributor N:

I prefer the Kreg Pneumatic over the Castle and Ritter. I looked at all three when purchasing and actually prefer the size and shape of the pocket holes better that the Kreg system makes. I've had an automatic system for over 5 years and have had no repairs and no downtime with the machine.

From contributor A:

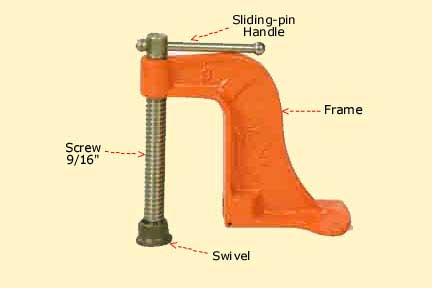

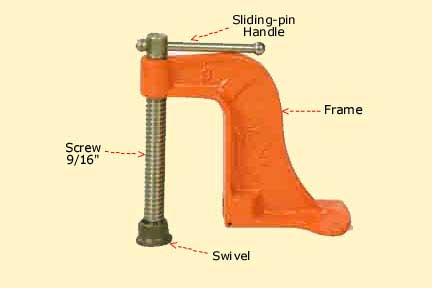

A few of you mentioned "creep" and getting an uneven match on the frames. I only do about 1 kitchen a month so production isn't so great that I need a hydraulic hold down, but Jorgensen makes a hold down clamp that I use, and I never have creep issues. It’s holds the 2 pieces tight to a flat table, and I have had better luck this way than with the vice grip style clamps or welders clamps.

Click here for full size image

From contributor H:

I just had to respond to this and put in a good word for Ritter as we bought a drill and face frame assembly table from them in the early 1980's. It was one of the best purchases we ever made. It has speedy production, short training time and strong jointing. We've always used glue on our joints and still have the original Formica tables. The original Baldor motor is still running. It has used quite a few drill bits and counterbores, but I go through maybe three sets a year and we built 70 face framed kitchens last year. We've been in business since 1971.

I have never ordered a single replacement part for either machine from Ritter and I bet I can get 75% of the original purchase price for the pair. I did put a new switch, cord end and belt on the drill a few years ago. The original ARO driver that came with the machine is still kicking. You will not be disappointed with their products – they are a great investment.