Question (WOODWEB Member) :

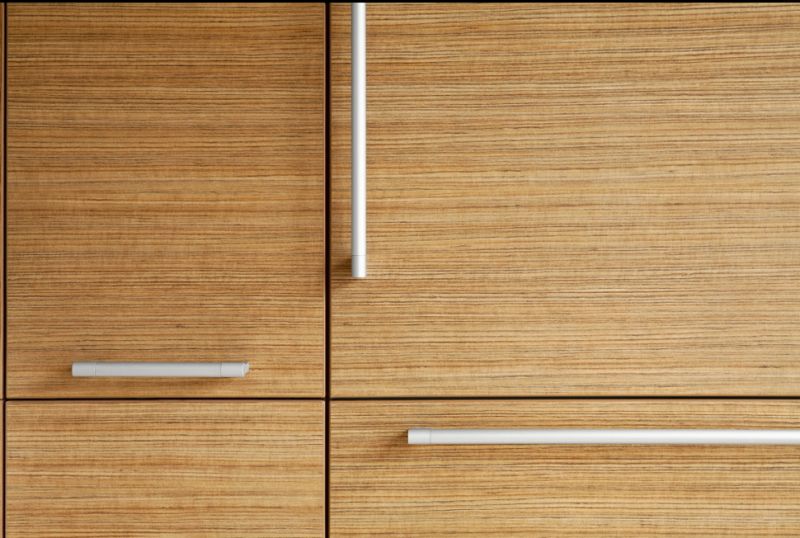

Crystal Cabinet Works up in sunny MN makes a couple lines of contemporary fronts, all doors and drawer fronts flush. Photos for the look are below. There are two offerings. One with taped edges, tape matches faces. The other is with 1/8" solid edges, species matches faces. Of course the one with solid edges carries a higher price.

Unfinished doors in, say, a rift-sawn white oak look might carry a material cost of what? The MDF core, edges, veneers, adhesive, all might come to $12 per square foot? Am I close? The solid edge version is going to carry a little more cost, of course. Not much more, we're talking material costs here. But let's say a shop is set up with equipment to make either. Which door then gets the higher labor cost, including burden costs for machine time, etc.?

Forum Responses

(Cabinetmaking Forum)

From Contributor C:

My short answer is it depends. The stuff in your picture is mismatched - basically cut sheets. If you shop well you can get five piece doors at a good cost. To do a proper matched veneer kitchen, there is a lot of labor in laying out the veneer faces so they match vertically and side to side with full veneer plates (leaves) side to side. Each panel needs to be made separate and cut carefully to align with adjacent panels, the veneer leaf with will vary for each panel slightly for a true balanced effect on each panel and overall. The effect can be dramatic. However that is not what your pictures indicate, the veneer may be reconstituted also, but it's mismatched for the most part. The banding difference is minimal. We use an in house made 2-ply veneer from the same log as the project which is about .050" before sanding. Some request 3mm (1/8) material with 2.5mm radius.

We are not in the kitchen business but we do contract veneer work for a bunch of companies. I am continually amazed how much time it takes to do this correctly for large kitchens. By the same token, smaller straight forward kitchens come in quite reasonable. Attached is a pic of a small local job we did.

Actually banding the panel first and then veneering is much more time consuming and much more expensive for materials. I don't do much of that except for the rarest of jobs where the price can be justified. Now if you’re trying to narrow it down to just the difference between a solid band and a taped edge leaving out the rest of the construction, I don't think there's going to be much difference at all outside of the material costs as long as your still buying the solid banding and applying it with an edge bander. Where would the extra labor costs come from?