From Gene Wengert, forum technical advisor:

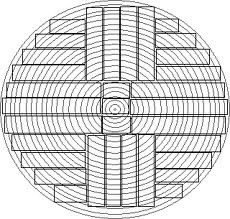

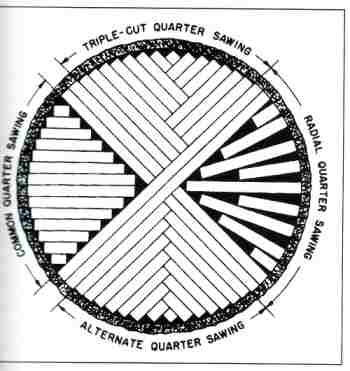

I am continually amazed of the incorrect info on the Internet about how to quartersaw and what lumber is quartersawn and what is rift. This is a good diagram of quarter sawing methods. The most figure will come from the right-most pattern, but it will have the lowest yield. Every piece is 100% quartersawn - that is the grain or annual rings are at a perfect 90 degrees to the face. The bottom is the way many people do quarter sawing, but there is a lot of rift - the rings are at an angle between 45 to 75 degrees to the face.

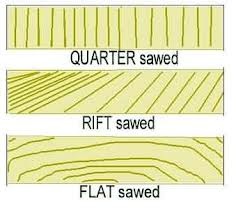

The left figure has more figure than the bottom, but still has a lot of rift. The top will have the least figure and the least quartersawn, but turning is minimized as you saw three pieces before turning. The second photo shows the end grain pattern for quarter, rift and flat sawn. Note that q-sawn is 75 to 90 degrees to the face, rift is 45 to 75, and flat is 0 to 45 degrees. The most figure or ray fleck on the face of the lumber will be with quartersawn. Rift will not show much fleck, but will have the straight grain lines on the face that quartersawn also has.

Forum Responses

(Sawing and Drying Forum)

From contributor A:

That's a great chart. How would one go about cutting radial quarter sawn like on the chart? Could a band mill do something like this?