Quartersawing, Rift Sawing, and Plain Sawing Explained

This authoritative explanation with photos and drawings will clear up the widespread confusion about the various ways of sawing logs for grain. May 27, 2014

Question (WOODWEB Member) :

I am sawing a walnut tree in order to make the fronts for drawers and am looking for opinions on which cut is best to bring out the grain in the walnut- rift, plain saw, or quartersawn?

Forum Responses

(Sawing and Drying Forum)

From Contributor P:

In my opinion I would go with plain sawn.

From contributor R:

A whole tree for drawer fronts? Either a small tree, or lots of drawers! It depends on furniture style - contemporary looks better with rift or quarter, traditional looks better with plain.

From contributor Y:

I generally rift cut walnut. Quarter sawn walnut just does not have the figure that oak or sycamore has. How are you sawing the logs yourself? What size logs?

From Gene Wengert, forum technical advisor:

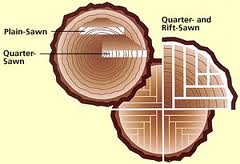

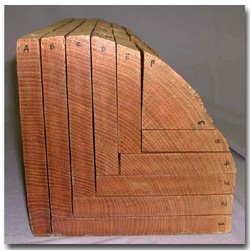

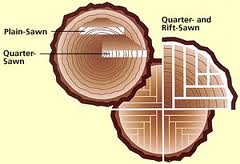

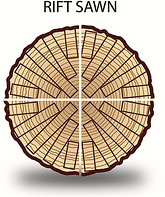

Unfortunately someone started showing the grain for plain, rift and quarter incorrectly and now the internet is full of this error. If the rings are at 75 to 90 degrees to the surface, it is quarter sawn, 45 to 75 is rift sawn and 0 to 45 is plain sawn. Stated another way, if the piece is parallel (with a few degrees) to the radius (pith to bark line), it is quarter sawn; if it is close to a radius, then rift; and perpendicular to the radius, plain or flat sawn.

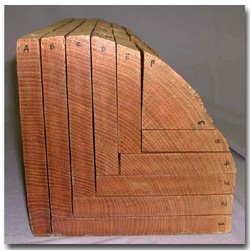

Here are some pictures of the correct information. The first shows the grain patterns for oak. The next shows a 100% plain and quarter sawn piece with the typical quarter sawing technique (right side) that produces both quarter and rift. The third shows the typical quarter sawing technique with pieces A, B, C (leftmost vertical pieces) and 1, 2 and 3 (bottom right) are indeed quarter sawn as the grain is nearly vertical. However, D, E, 4, and 5 are rift with F being scrap. The next posting shows an incorrect description.

From Gene Wengert, forum technical advisor:

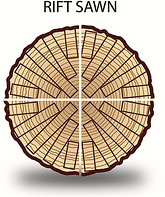

Here are two examples of errors. Every piece in this first diagram has the rings at 90 degrees so every piece is 100% quarter sawn and is not even close to rift sawn. The label is incorrect. And below that is another error where this sawing technique, which is really live sawing, does not produce all plain sawn lumber. The three pieces at the top and three at the bottom are indeed plain or flat sawn, but as we go to the wider pieces, they will have mostly rift grain. The three wide center pieces will have a very small strip of flat grain in the center, then a very small bit of rift and then mostly quarter sawn, so it will be quarter sawn lumber. Again, the label is incorrect. The final picture is again labeled incorrectly, as the wider pieces are quarter sawn but the narrower ones are rift.

From the original questioner:

Thanks for the info Gene. It clears up a lot of misinformation. As a forester I am familiar with the different sawing patterns, but finding pics of what walnut looked like it was problematic for me. I am used to the oaks and maple - rift, quarter sawn, and plain. There is a mill that was getting ready to saw some walnut (we have thousand cankers here in East Tennessee) so I am being careful on where the walnut is as well. I'll be going with plain sawn from the same tree so I can keep the pattern. You have given me good info in the past on air drying, but I'll be kiln drying the walnut.

From contributor Y:

Thanks, Gene. I stand corrected. I plain saw walnut. Based on those diagrams, I've never rift sawn a log, and don't plan on it anytime soon!

From Gene Wengert, forum technical advisor:

The number one rule when drying walnut is to end coat twice - two coats that is. Correction: It is not a rule; it is much closer to a commandment.